Preparation method of reversible photoinduced deformation liquid crystal high polymer and carbon nano tube composite thin film

A carbon nanotube composite and carbon nanotube film technology, which is applied in the field of preparation of liquid crystal polymer and carbon nanotube composite film, can solve the problems of low material sensitivity and stability, difficult orientation of liquid crystal polymer, etc. Effects of defects and electrostatic aggregation, improved mechanical properties, simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

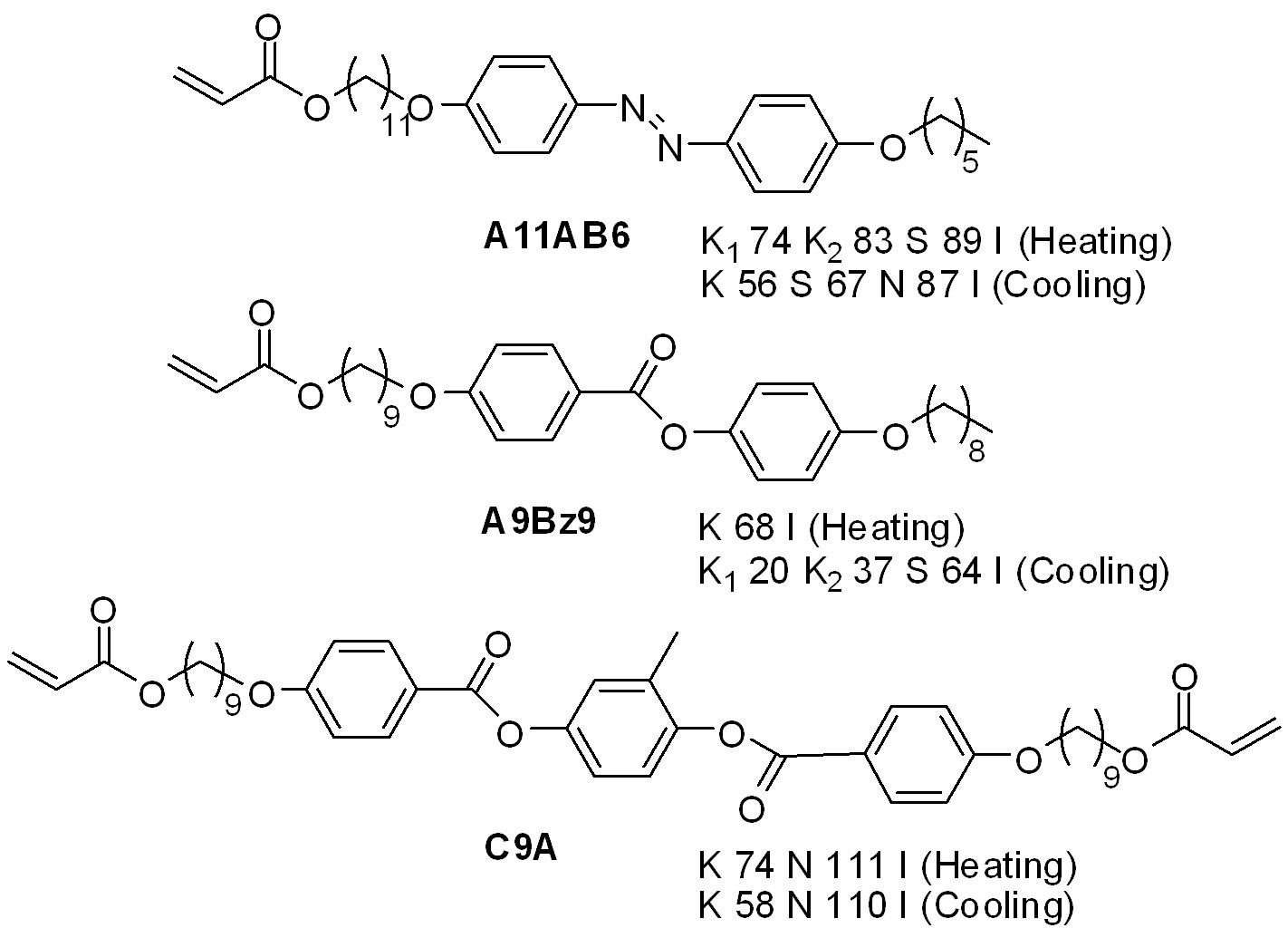

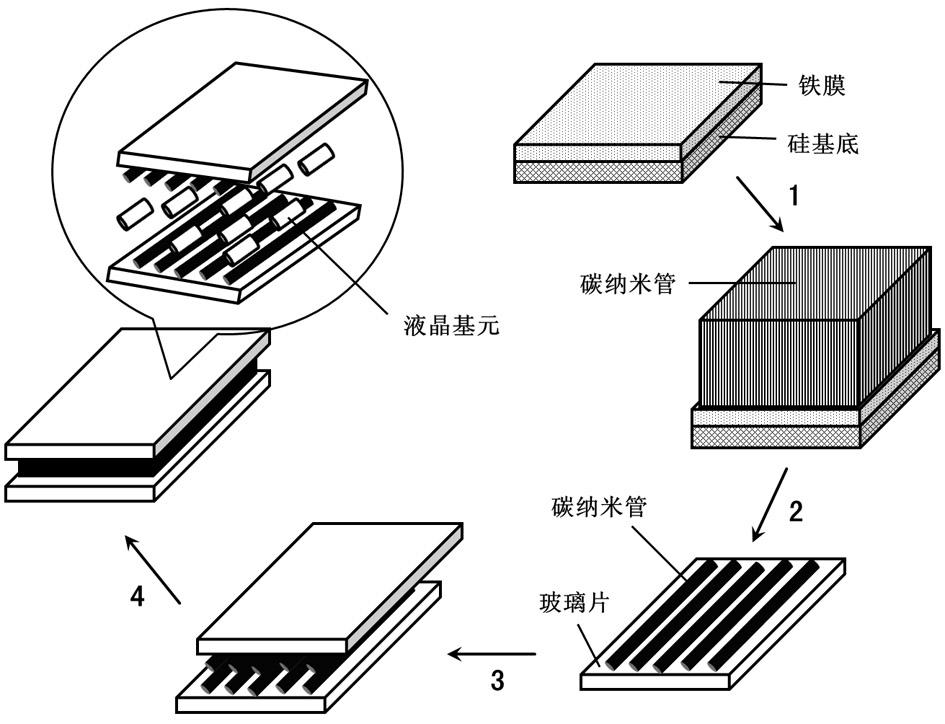

specific example 1

[0037] Highly oriented carbon nanotube films were prepared by dry spinning and fixed on glass substrates. The two glass substrates are respectively covered with two layers of carbon nanotube films, and the glass sheets are fixed in parallel with an interval of 30 microns to make a liquid crystal cell. Mix the two monomers A11AB6, A9Bz9 and the crosslinking agent C9A in a molar ratio of 1:1:3 and a photoinitiator with a molar percentage of 1%, heat it to 90 degrees Celsius, melt and inject it into the liquid crystal cell, and the liquid crystal material in an amorphous state. Cool down to 77 degrees Celsius at a rate of 0.1 degrees Celsius / second, and the liquid crystal is in the nematic phase. Then keep the temperature at 77 degrees Celsius, filter the high-pressure mercury lamp light source to obtain monochromatic light with a wavelength of 547 nanometers, and irradiate for 2 hours to carry out the polymerization reaction. Then cool down to room temperature, open the liquid...

specific example 2

[0039] Highly oriented carbon nanotube films were prepared by dry spinning and fixed on glass substrates. Two glass sheets respectively covered with a layer of carbon nanotube film are fixed in parallel with an interval of 20 microns to make a liquid crystal cell. Mix the two monomers A11AB6, A9Bz9 and the crosslinking agent C9A in a molar ratio of 1:1:3 and a photoinitiator with a molar percentage of 1%, heat it to 89 degrees Celsius, melt and inject it into the liquid crystal cell, and the liquid crystal material in an amorphous state. Cool down to 76 degrees Celsius at a rate of 0.1 degrees Celsius / second, and the liquid crystal is in the nematic phase. Then keep the temperature at 76 degrees Celsius, filter the high-pressure mercury lamp light source to obtain monochromatic light with a wavelength of 547 nanometers, and irradiate for 2 hours to carry out the polymerization reaction. Then cool down to room temperature, open the liquid crystal cell, and peel off the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com