Master-slave hydraulic mechanical arm system of high-voltage hot-line operation robot

A robot main, high-voltage live technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of difficult inspection and elimination of faults, poor operation flexibility, difficult control procedures, etc., to achieve convenient operation, reliable operation, stable and reliable performance. , The effect of flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the utility model is described further.

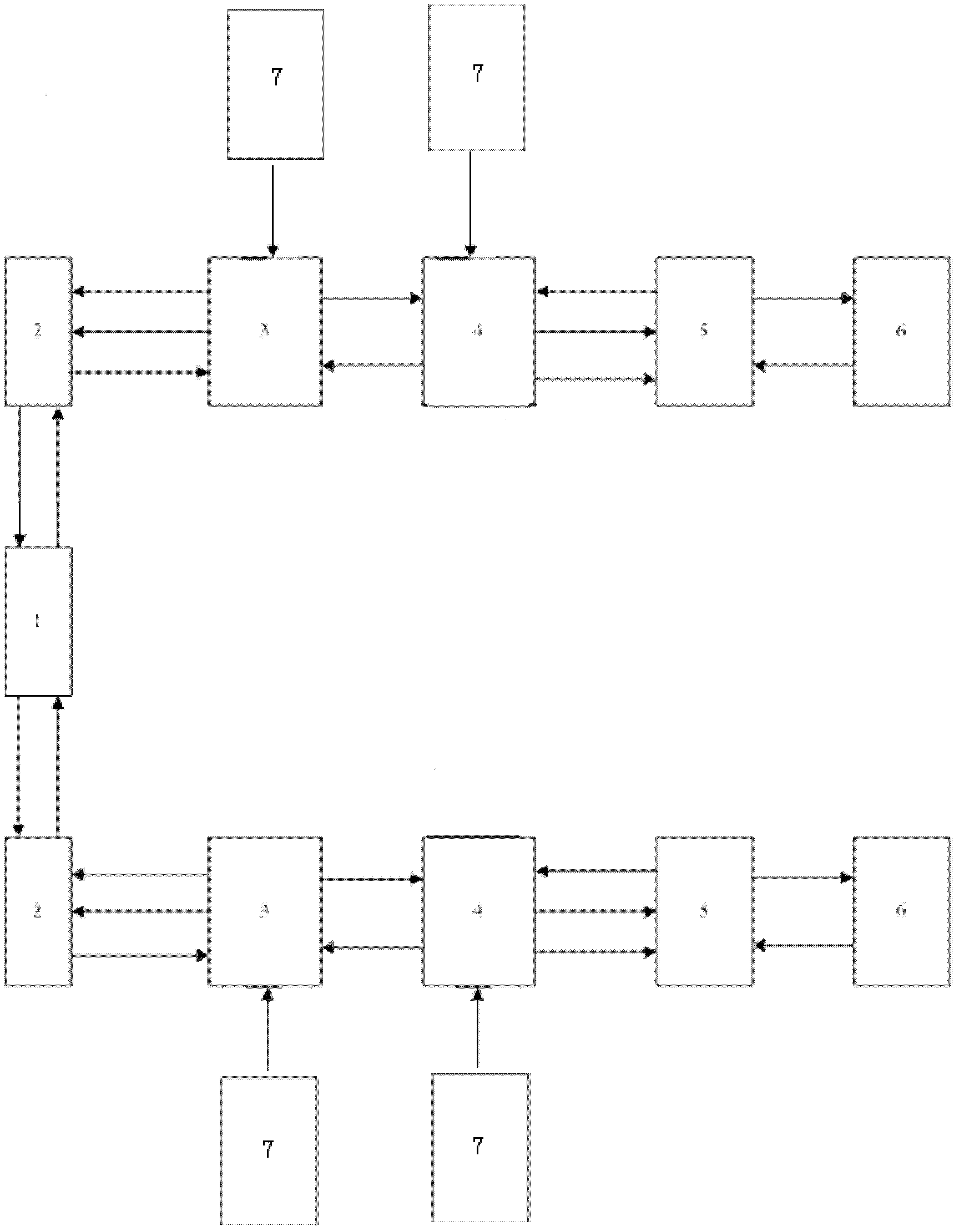

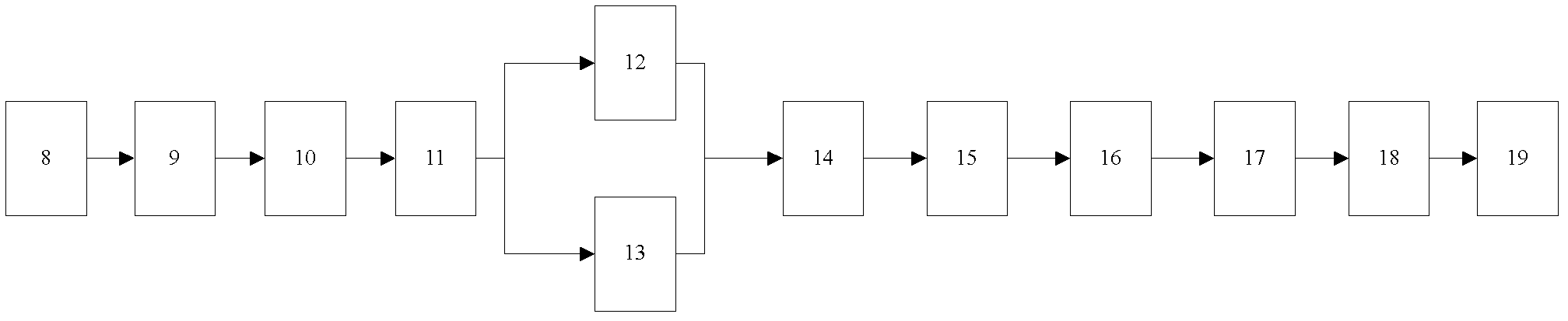

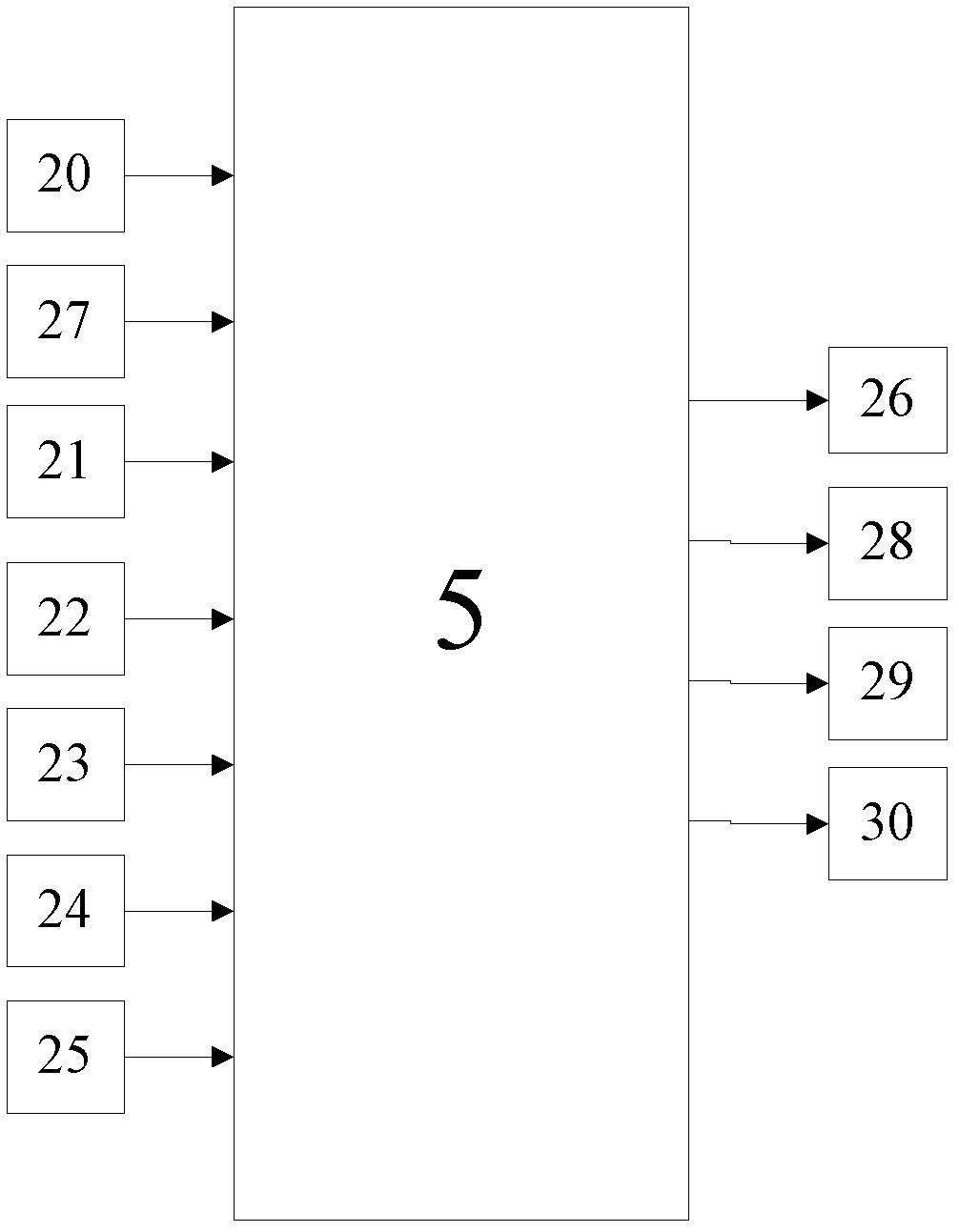

[0043] figure 1 Among them, a master-slave hydraulic manipulator system for a high-voltage live working robot, which includes a hydraulic oil source 1, a manipulator 2, a hydraulic servo driver 3, an optical fiber, a master hand controller 4, a master hand 5, a handheld terminal 6 and a power supply 7 The mechanical arm 2 is connected to the hydraulic servo driver 3 through the control bus, the power bus and the position signal bus, and is connected to the hydraulic oil source 1 through the oil return pipe and the oil inlet pipe; the hydraulic servo driver 3 communicates with the main hand controller 4 through an optical fiber; The main hand controller 4 is connected with the main hand 5 through the control bus, the power bus, and the state signal bus; the main hand 5 is connected with the handheld terminal 6 through the state signal bus and the command signal bus; C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com