Preparation method of electrode material of silver/graphene thin film supercapacitor

A graphene film and supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, capacitors, electrolytic capacitors, etc., can solve the reports, physical and chemical properties that have not yet been seen in the preparation of silver/graphene film supercapacitor electrode materials Loss and other problems, to achieve the effect of superior supercapacitor performance, promotion of charge transfer, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.025g of graphite oxide and disperse into 100mL of ultrapure water for ultrasonic dispersion for 1h, add 0.025g of silver nitrate and magnetically stir and mix for 30min, then add 0.04g of sodium borohydride and continue stirring for 2h to obtain a bright brown solution. Add the above solution into a three-necked flask, add 2.5g of sodium borohydride again, raise the temperature to 80°C under a nitrogen protective atmosphere, and keep it warm for 1 hour to obtain a black suspension. The centrifugation speed is 6500r / min and the time is 15min. Ultrapure water After centrifugation and washing for 6 times, the film-like product was obtained by suction filtration, and washed 5 times with ultrapure water.

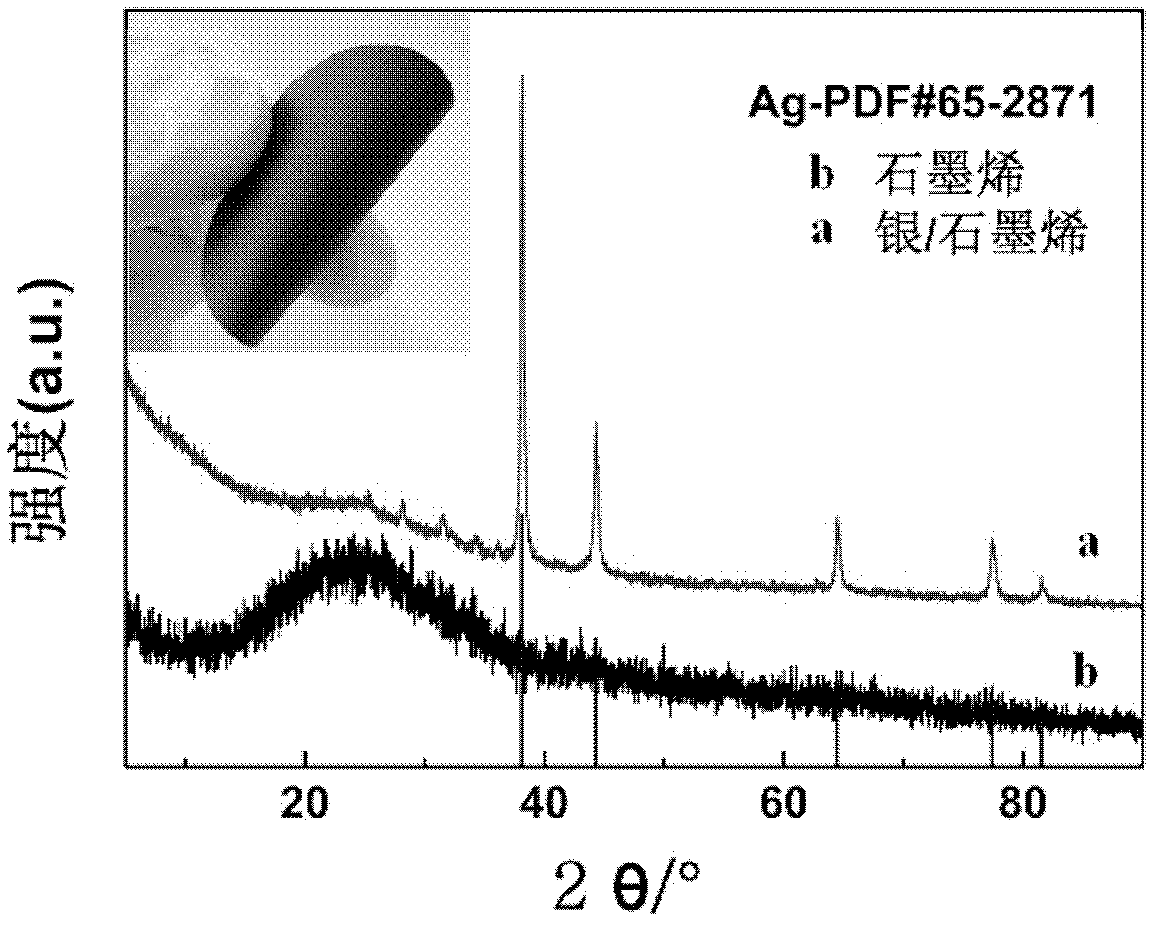

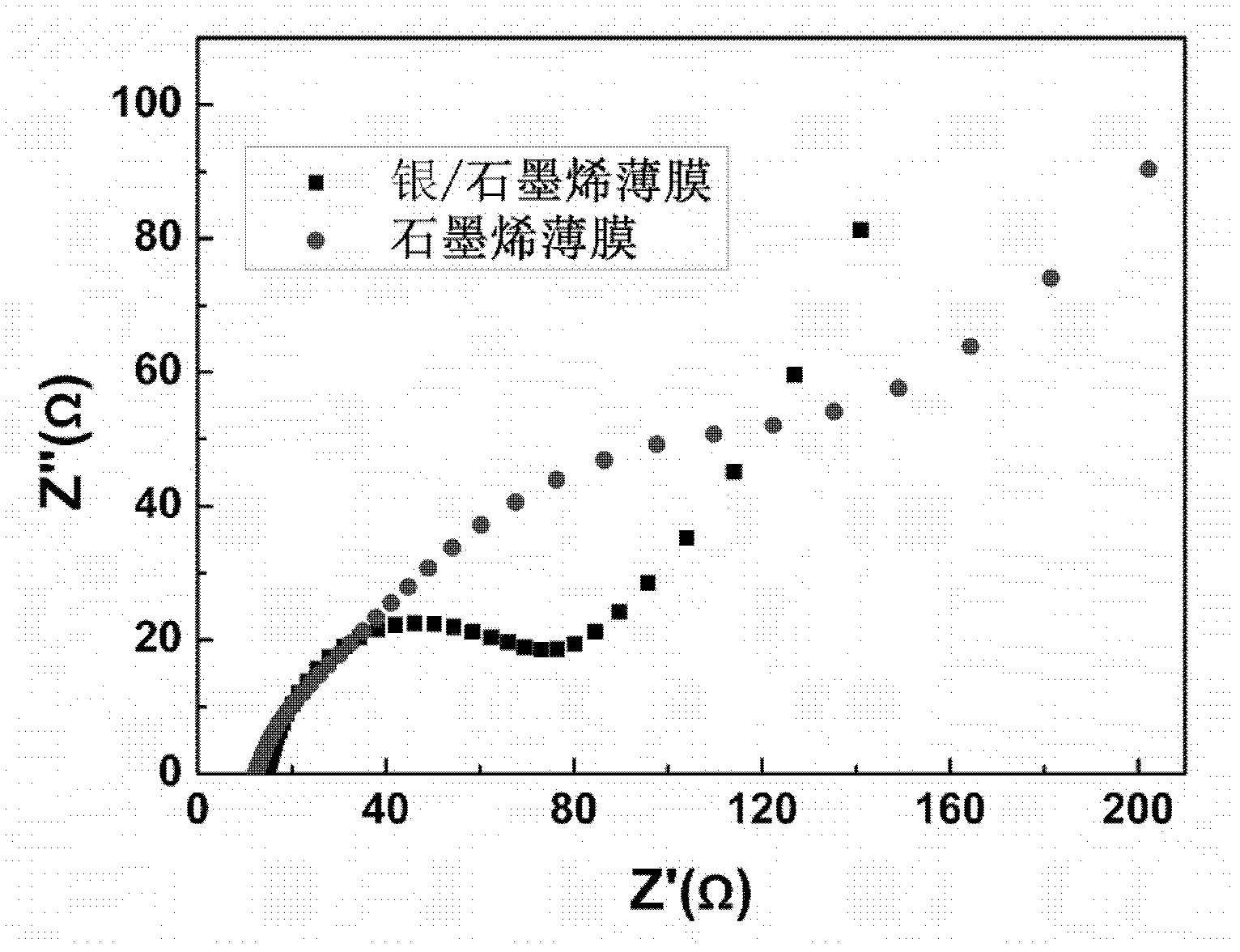

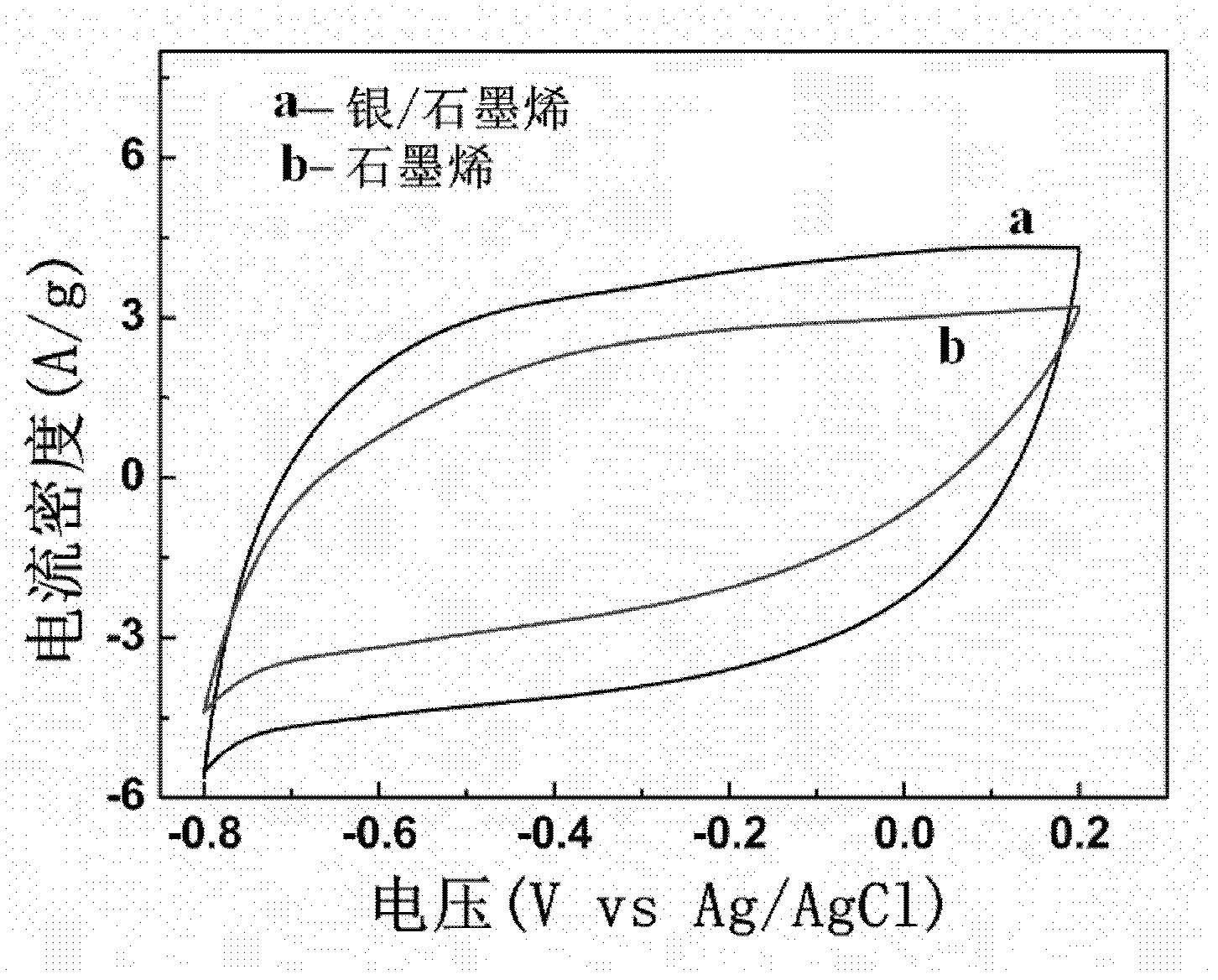

[0029] figure 1 For the comparison of the X-ray diffraction curves of the product and pure graphene, the steamed bread peaks of graphene appear in the figure, and several strong diffraction peaks match the PDF standard card 65-2871 of silver, indicating that the gr...

Embodiment 2

[0035] Weigh 0.025g of graphite oxide and disperse it into 50mL of ultrapure water for 2 hours, add 0.005g of silver nitrate and stir for 60 minutes, then add 0.025g of sodium borohydride and continue to stir for 1 hour to obtain a bright brown liquid. The liquid was added into a three-necked flask, and 1.25 g of sodium borohydride was added again. Under a nitrogen protective atmosphere, the temperature was raised to 70° C. and kept for 3 hours to obtain a black liquid. The centrifugation speed is 9000r / min and the time is 5min, and the ultrapure water is centrifuged and washed 10 times, and then the film-like product is obtained by suction filtration, which can be washed 10 times with ultrapure water. X-ray diffraction analysis shows that it is a silver / graphene composite component, impedance analysis shows that the charge transfer resistance is low, cyclic voltammetry curve analysis has high specific capacitance performance, and constant current charge and discharge analysis ...

Embodiment 3

[0037] Weigh 0.025g of graphite oxide and disperse it into 80mL of ultrapure water and sonicate for 1.5h, add 0.02g of silver nitrate with magnetic stirring and mix for 30min, then add 0.05g of sodium borohydride and continue stirring for 3h to obtain a bright brown liquid. The liquid was added into a three-necked flask, and 1.5 g of sodium borohydride was added again. Under a nitrogen protective atmosphere, the temperature was raised to 85° C. and kept for 1 hour to obtain a black liquid. The centrifugation speed is 8000r / min and the time is 10min, and the ultrapure water is centrifuged and washed 5 times, and then the film-like product is obtained by suction filtration, and the ultrapure water is washed 7 times. X-ray diffraction analysis shows that it is a silver / graphene composite component, impedance analysis shows that the charge transfer resistance is low, cyclic voltammetry curve analysis has high specific capacitance performance, and constant current charge and dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com