Salt mist system of multifactor environmental aging test device for composite material

An aging test and composite material technology, applied in the field of salt spray systems, can solve the problems of large diameter of salt spray particles, affecting the sample workpiece, corrosion, etc., to achieve the effect of improving effectiveness, achieving sedimentation, and achieving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

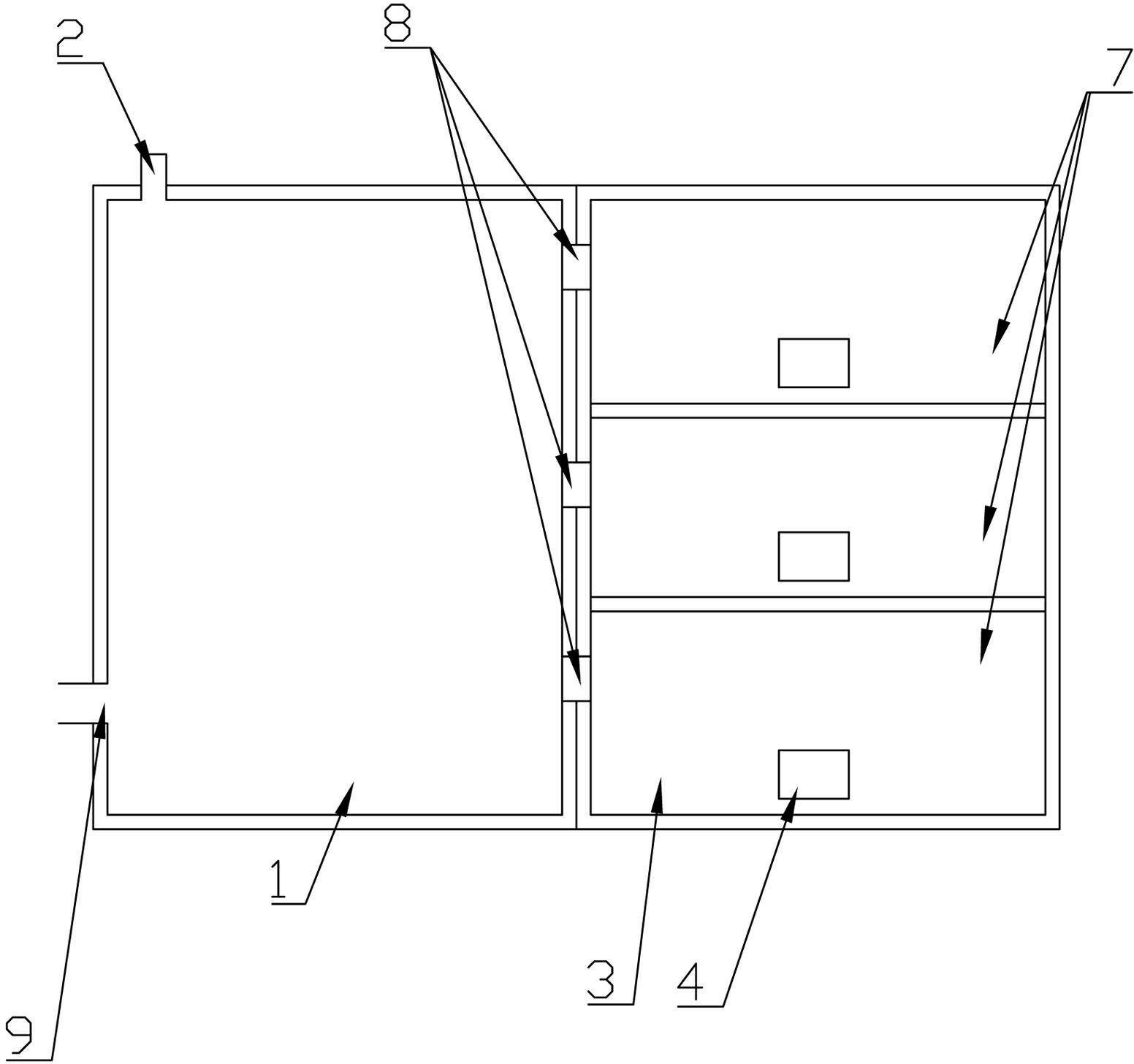

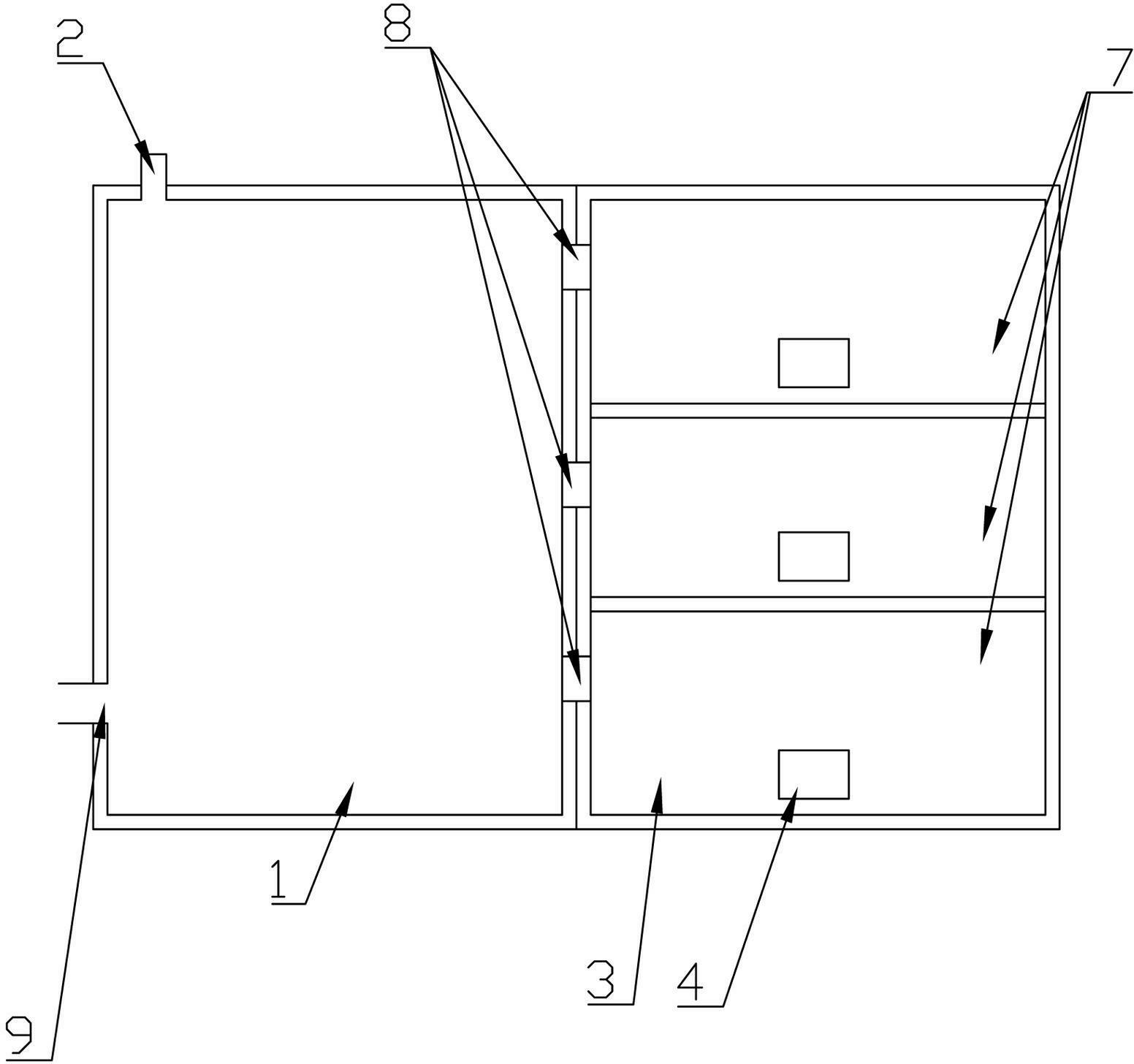

[0013] refer to figure 1 , a salt spray system of a multi-factor environmental aging test device for composite materials, comprising a salt spray generating chamber 3 and a test working chamber 1, the salt spray generating chamber 3 being connected to the testing working chamber 1, and the salt spray generating chamber 3 An ultrasonic salt spray generator 4 is provided. The test chamber 1 and the salt mist generation chamber 3 form a closed space.

[0014] The working principle of the ultrasonic salt spray generator 4 is to use the ultrasonic generator and the transducer to generate self-excited oscillations, radiate strong ultrasonic waves into the water, and the ultrasonic waves pass through the water and the semi-permeable membrane to act on the salt solution to be atomized in the salt spray chamber. The microbubbles in the saline solution vibrate under the action of the sound field. When the sound pressure reaches a certain value, the microbubbles expand rapidly and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com