Electric transmission and transformation equipment contact luminous temperature sensing cap system

A power transmission and transformation equipment, light-emitting technology, used in signal transmission systems, thermometers, thermometers, etc., which are directly sensitive to heat-sensitive electrical/magnetic components, can solve the problem of unintuitive, power transmission and transformation equipment contacts can not be remotely known, transmission Problems such as outdated temperature measurement methods of substation equipment, to achieve the effect of simple wiring, increased use range, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

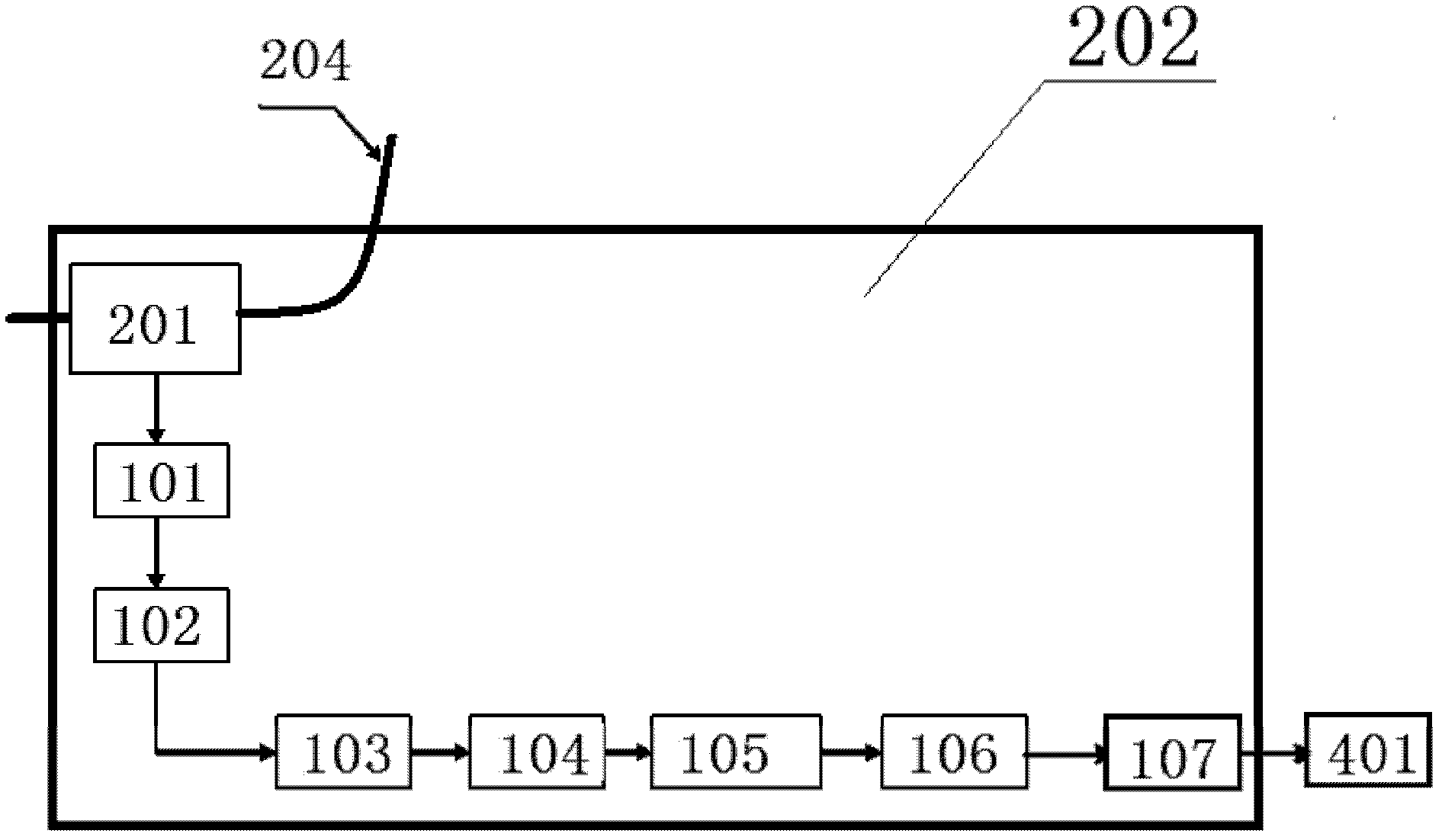

[0122] Example 1: figure 1 , Shows the circuit diagram of the high-voltage self-contained power supply device.

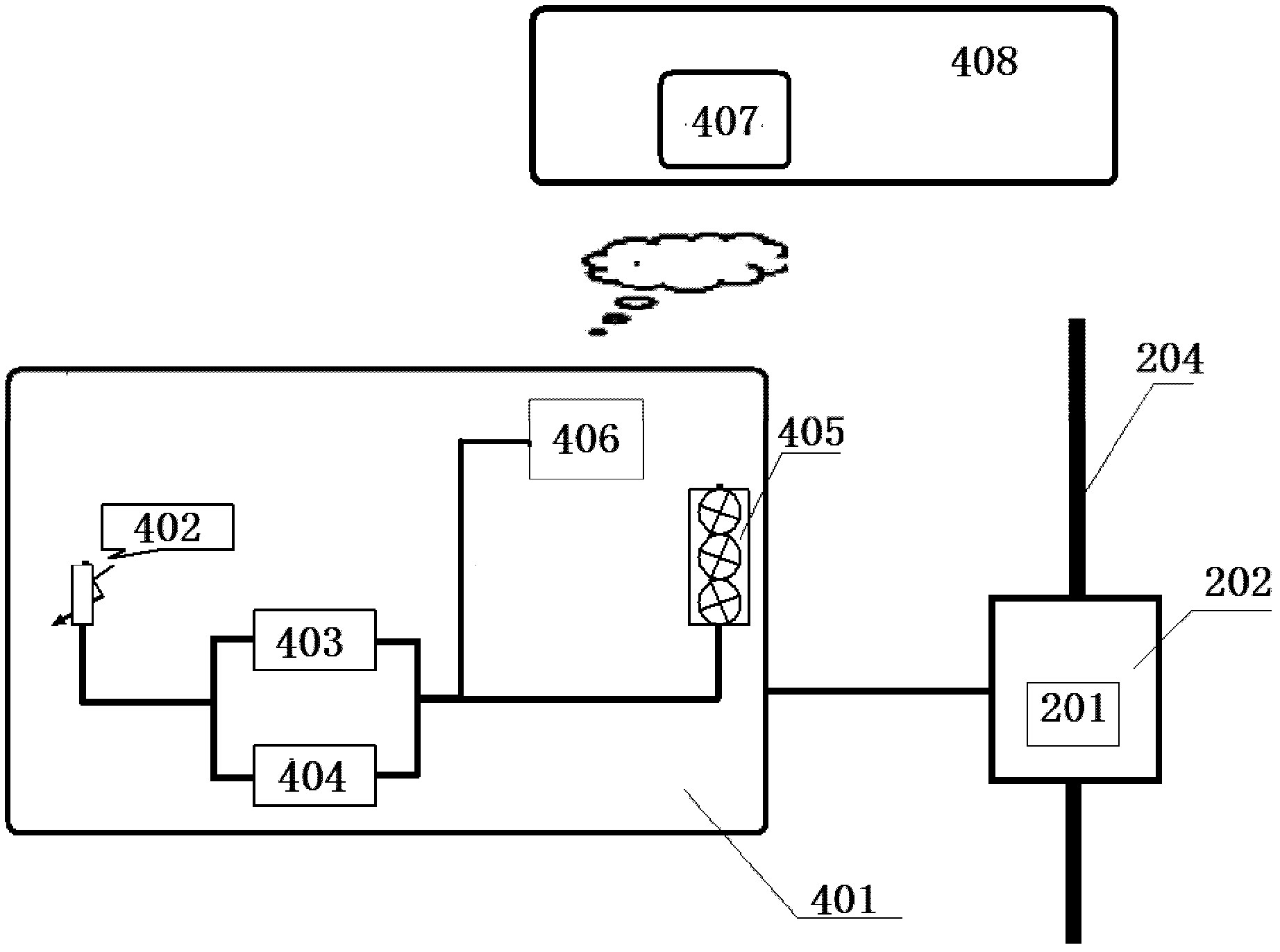

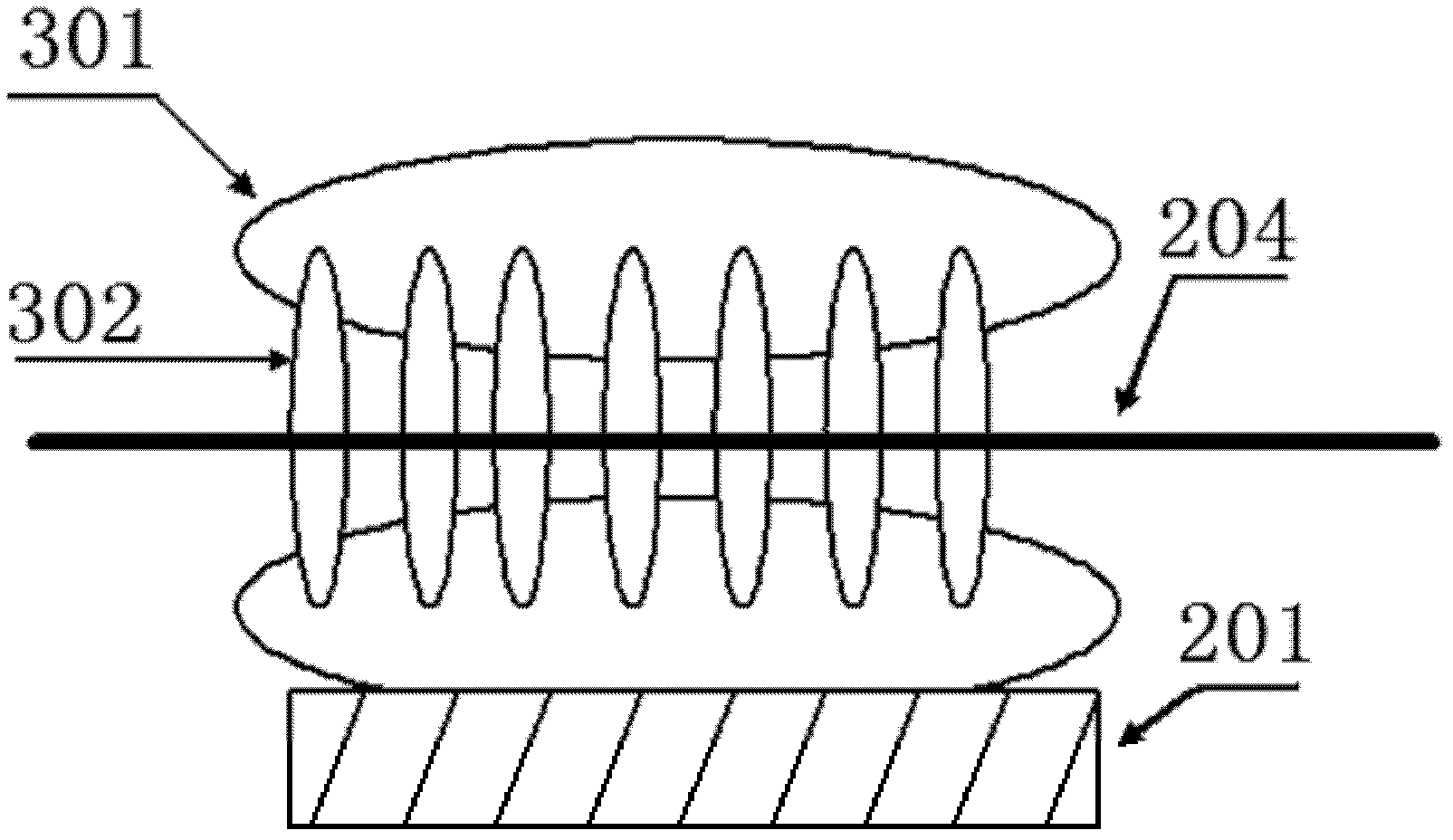

[0123] CT directly induces the AC voltage from the primary current, passes the smoothing reactance 101 and uses the full-wave rectifier bridge 102 to convert, obtains a relatively stable DC voltage on the stabilized capacitor 103, and then passes the voltage protection circuit 104, filter circuit 105 and The DC-DC module 106 and the current-limiting resistor 107 are converted into a 3.3V power supply for the electronic circuit in the light-emitting temperature sensing cap 401 of the contact of the power transmission and transformation equipment. When the CT is deeply saturated, both the induced voltage and the induced current rise significantly. After the smoothing reactance is added to the position between the CT and the full-wave rectifier bridge 102, it can share most of the high voltage induced by the CT and limit the current of the CT Output. The voltage protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com