Regenerative high-temperature air combustion energy-saving environment-friendly shuttle-type kiln

A high-temperature air, energy-saving and environmental protection technology, applied in the direction of improving energy efficiency, furnace, waste heat treatment, etc., to achieve the effect of significant energy-saving effect, improvement of technical level and energy utilization level, and significant economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

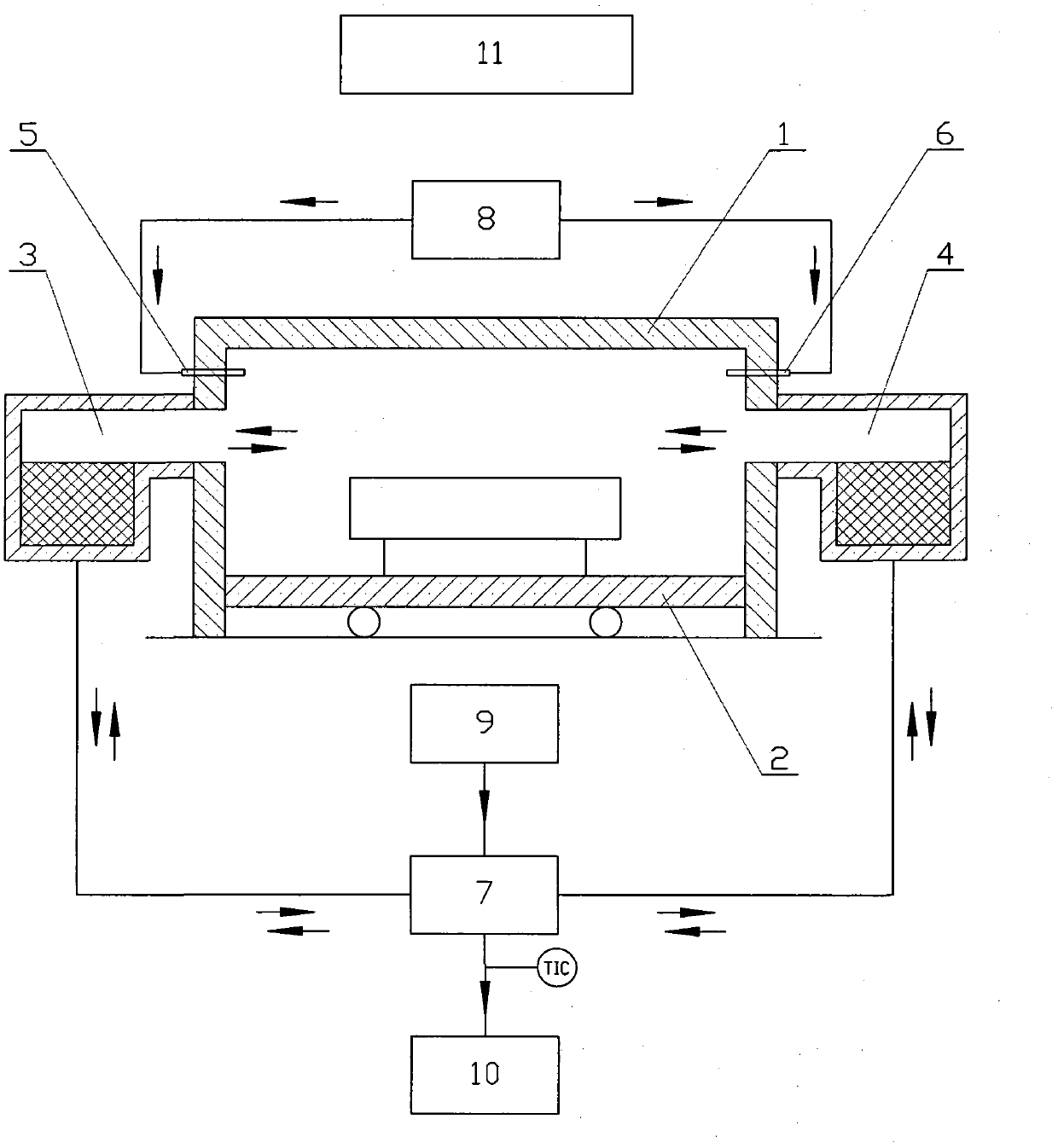

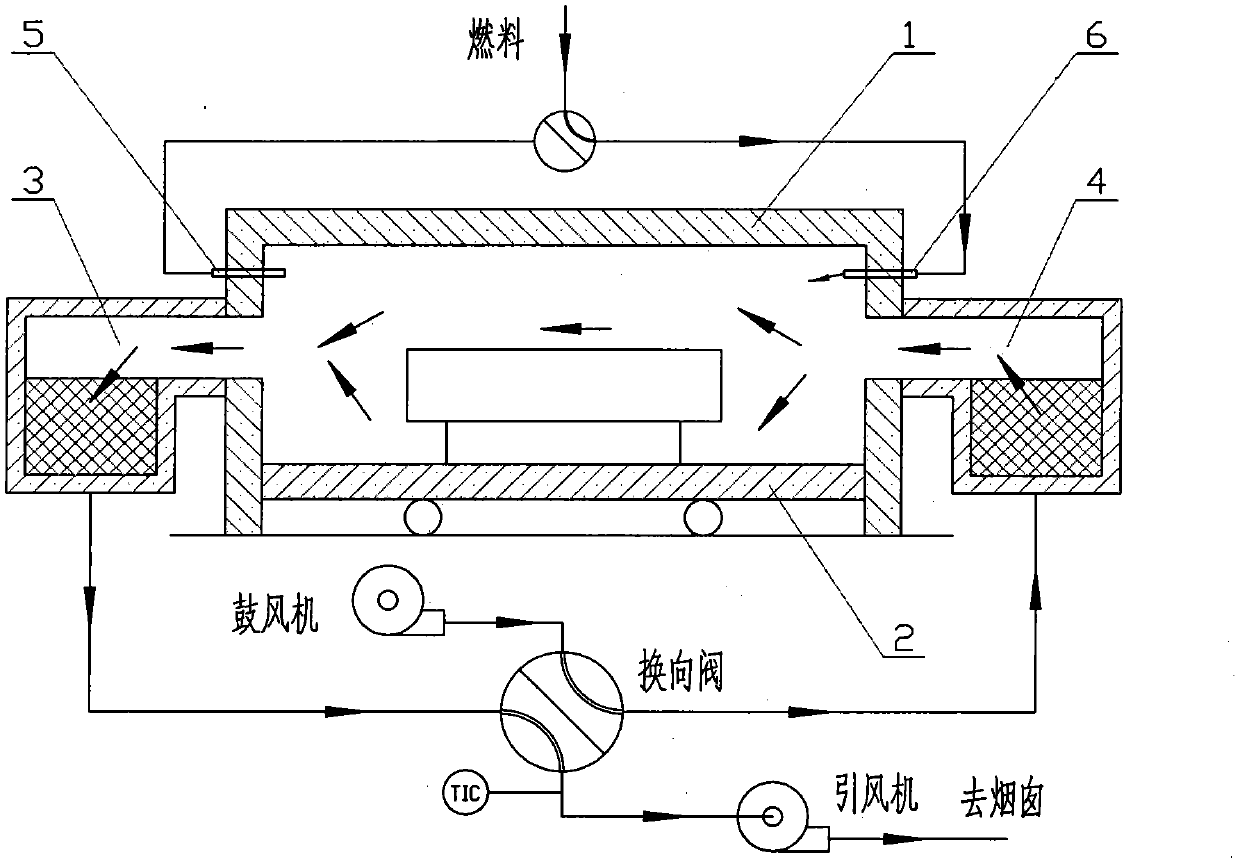

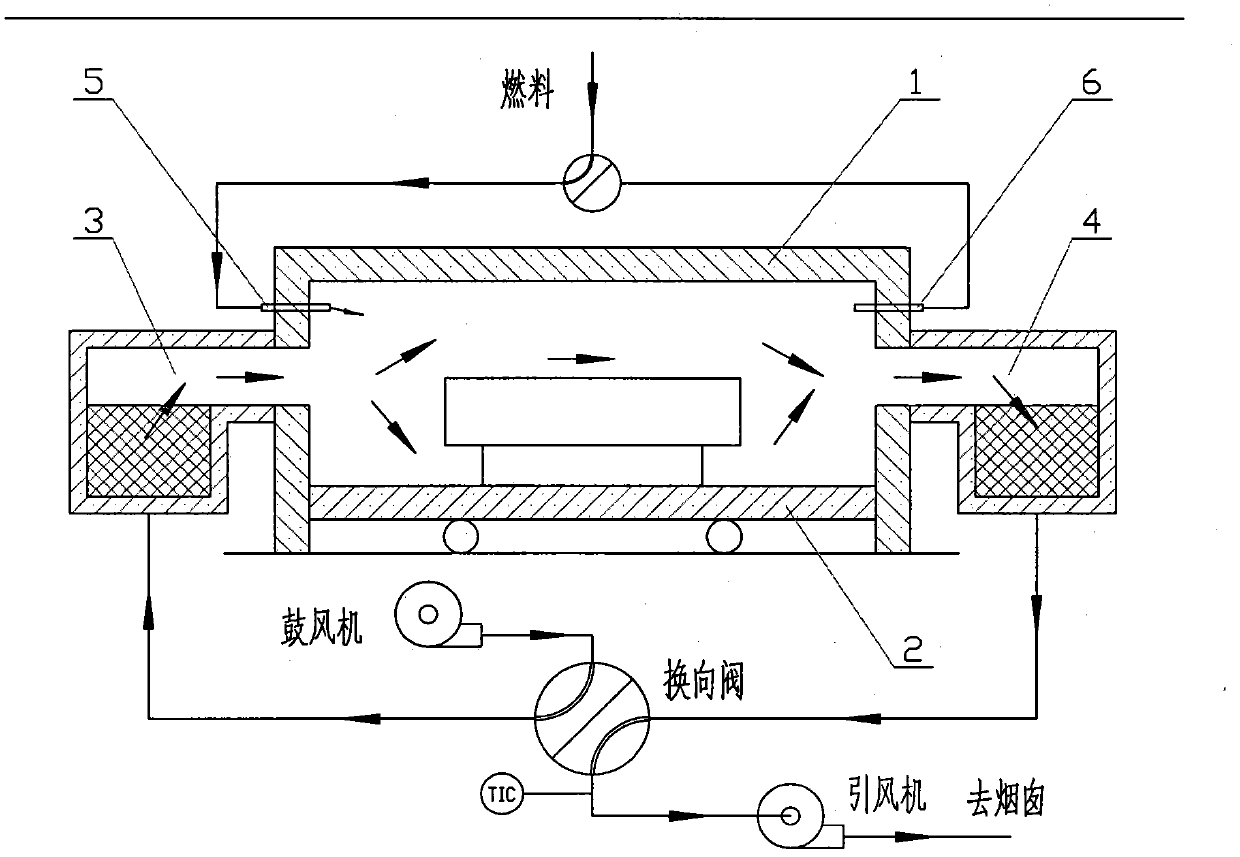

[0018] See figure 1 , Regenerative high-temperature air combustion energy-saving and environment-friendly shuttle kiln includes: furnace body 1, trolley 2, regenerator or regenerative burner 3, 4, fuel spray gun 5, 6, combustion air and flue gas reversal It consists of equipment 7, fuel supply equipment 8, combustion-supporting wind supply equipment 9, flue gas emission equipment 10, and automatic control and safety protection equipment 11.

[0019] The furnace body 1 is composed of a steel frame, side walls made of refractory and thermal insulation materials, a ceiling and a furnace door. The trolley 2 is composed of a steel car body, wheels, rails, and a platform made of refractory materials.

[0020] The regenerator or regenerative burners 3 and 4 are composed of shell, refractory insulation material and heat storage body; the heat storage body can be honeycomb ceramic or refractory pellets, or both can be used at the same time. When in use, the heat storage body can be divided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com