Integrated car plug

An integrated, spark plug technology, applied in spark plugs, electrical components, circuits, etc., can solve problems such as abnormal engine operation, and achieve the effect of solving the problem of misfire and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

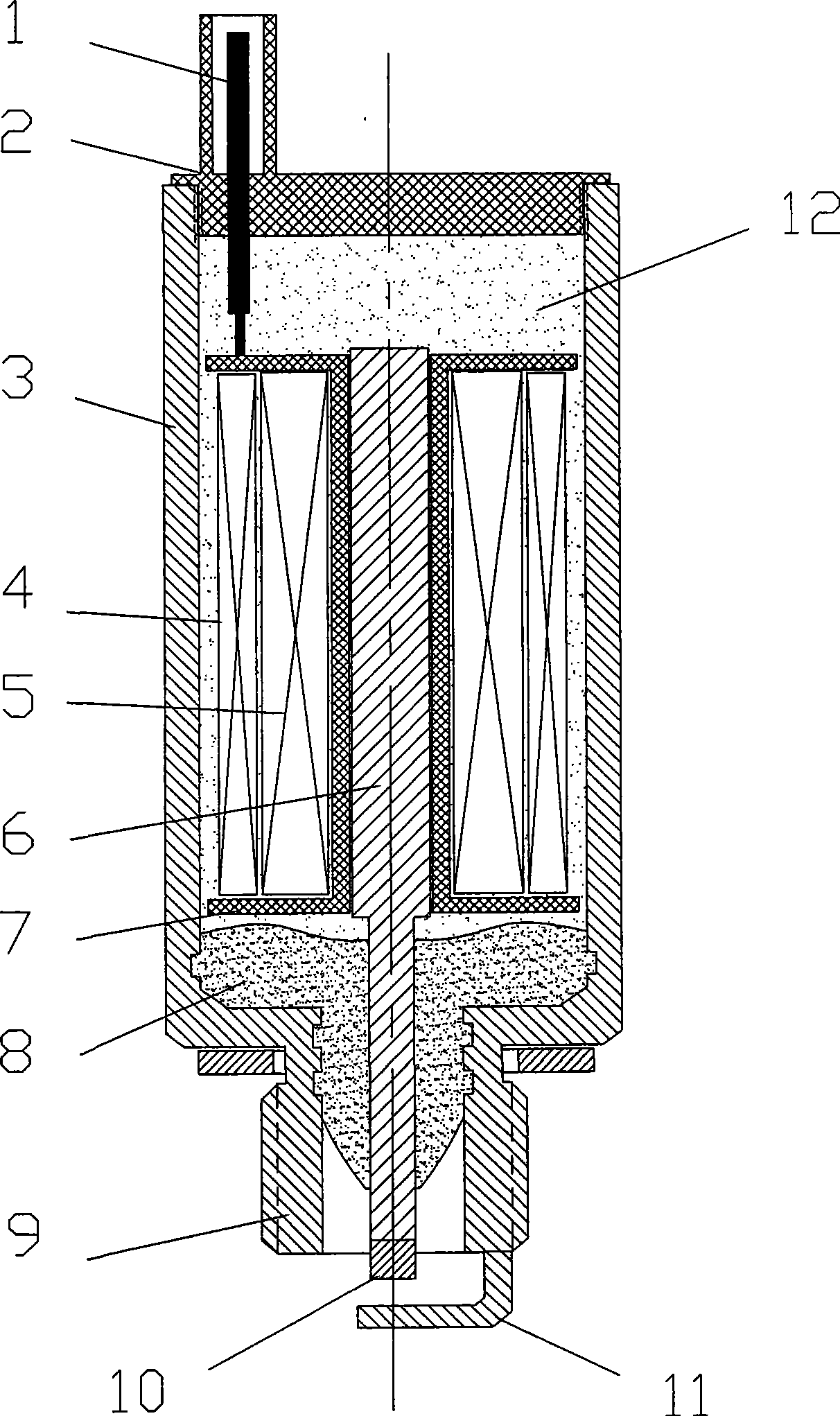

[0013] As shown in the figure, the one-piece automobile spark plug includes a threaded metal plug 9 and a center electrode 6 that is penetrated on the axis of the metal plug 9 and is isolated and fixed by a ceramic core 8 .

[0014] The upper end of the metal plug 9 is made into a cylindrical shell 3, and in its inner cavity, the low-voltage coil 4 and the high-voltage coil 5 wound on the wire frame 7 form an ignition coil, and the wire frame 7 is set on the center electrode 6, and the center electrode 6 As the iron core, a step-up transformer is formed.

[0015] The inner cavity of the cylindrical housing 3 is filled and sealed with resin 12, and the resin 12 is epoxy resin.

[0016] Both ends of the high voltage coil 5 are electrically connected to the cylindrical casing 3 and the center electrode 6 respectively.

[0017] Both ends of the low-voltage coil 4 are electrically connected to the cylindrical casing 3 and the lead-out electrode 1 respectively.

[0018] The cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com