Backlight module

A backlight module and backplane technology, applied in the field of backlight modules, can solve problems such as uneven brightness at the edge of the backlight module, abrasion of the light guide plate, cracking of the light guide plate, etc., to ensure the intensity of light and the uniformity of light, Avoid the effect of changing the light path and avoiding extrusion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

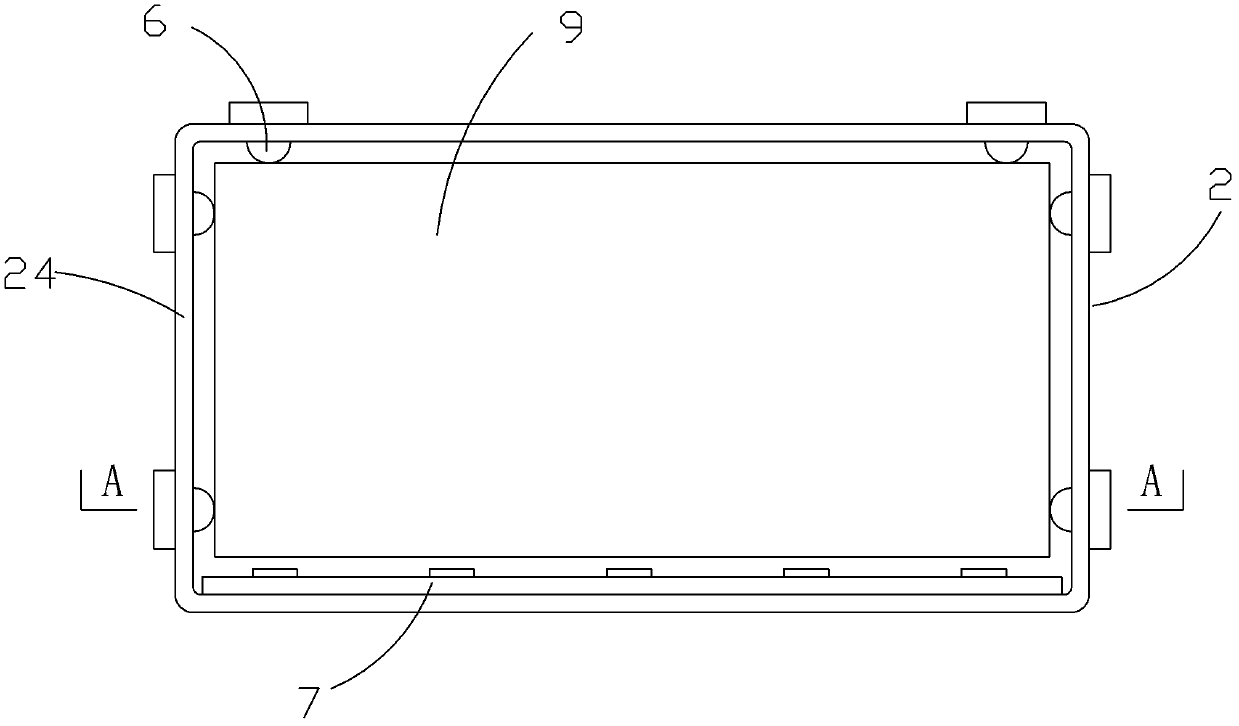

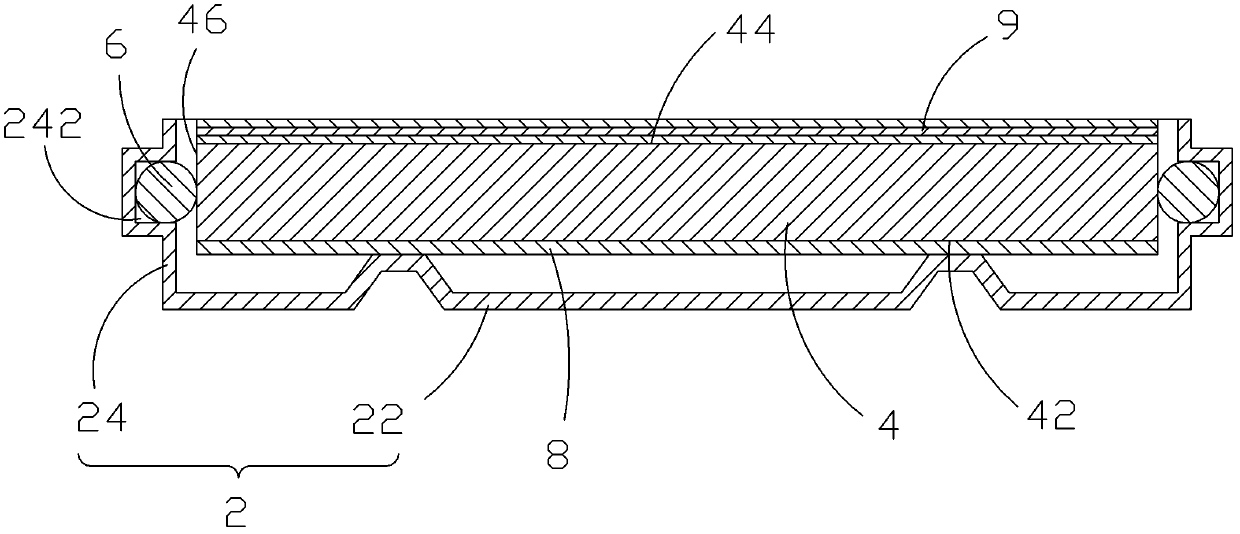

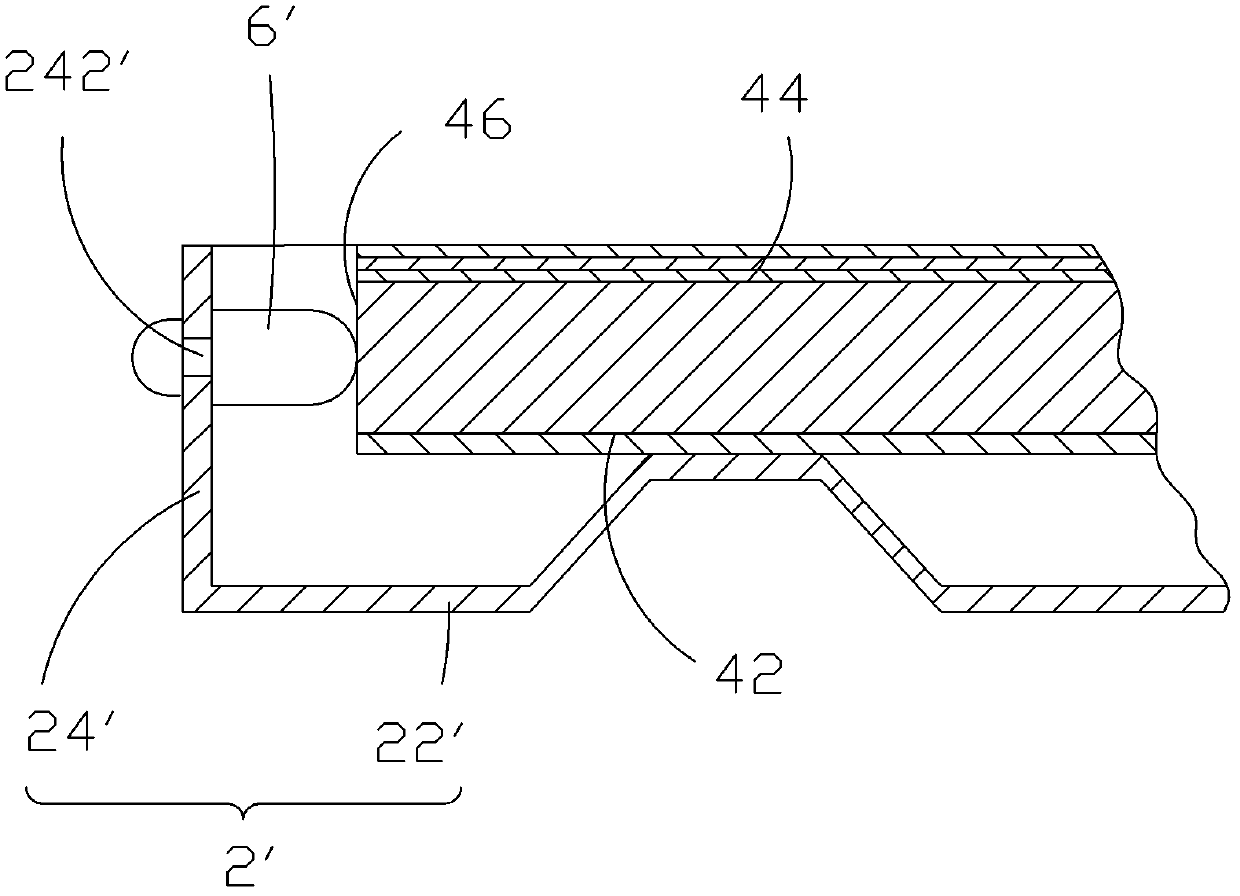

[0024] see figure 1 and figure 2 , as an embodiment of the backlight module of the present invention, the backlight module includes: a backplane 2, a light guide plate 4 disposed inside the backplane 2, and several elastic bodies 6 disposed between the backplane 2 and the light guide plate 4 . The backboard 2 includes a bottom board 22 and a plurality of side boards 24 vertically connected around the bottom board 22 . The light guide plate 4 includes a bottom surface 42 facing the bottom plate, a top surface 44 away from the bottom plate, and several side surfaces 46 connected between the bottom surface 42 and the top surface 44, and the several side surfaces 46 correspond to several sides facing the backplane 2. Side panels 24. Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com