Integrated linkage control valve bank for all-hydraulic coal mine drill

A linkage control and full hydraulic technology, applied in fluid pressure actuators, mechanical equipment, servo motor components, etc., can solve the problems of disassembly, maintenance and handling difficulties, many connecting hoses, and small maintenance space, etc., so as to facilitate maintenance , Reduce the chance of oil leakage and reduce the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

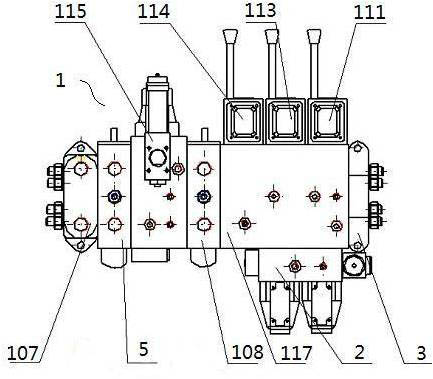

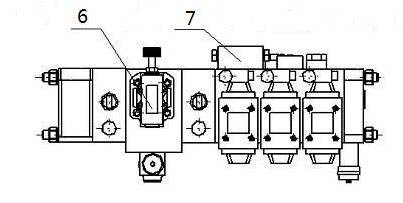

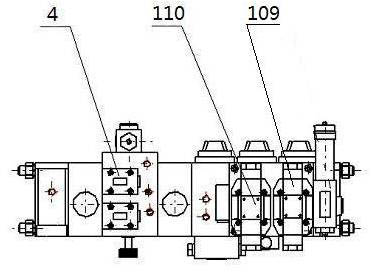

[0026] like figure 1 As shown, it is a structural schematic diagram of an embodiment of an integrated linkage control valve group for a fully hydraulic drilling rig for coal mines of the present invention; figure 2 for figure 1 top view of image 3 for figure 1 bottom view.

[0027] The integrated linkage control valve group for the fully hydraulic drilling rig used in coal mines in this embodiment includes a valve body 1 , and an oil channel is arranged in the valve body 1 .

[0028] The integrated linkage control valve group for the coal mine full hydraulic drilling rig of this embodiment also includes a rotating piece 107 connected to the motor 102 and a pushing piece 108 connected to the feed cylinder 103, both of which are three-position six Through multi-way reversing valve.

[0029] The integrated linkage control v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com