Method for increasing wheat straw anaerobic gas yield through pretreatment of catalysis-ammoniation on wheat straws in solid state at normal temperature

A technology of pretreatment and gas production, which is applied in the field of pretreatment, can solve the problems of long ammoniation pretreatment time, and achieve the effect of being suitable for large-scale production, saving operating costs and reducing engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

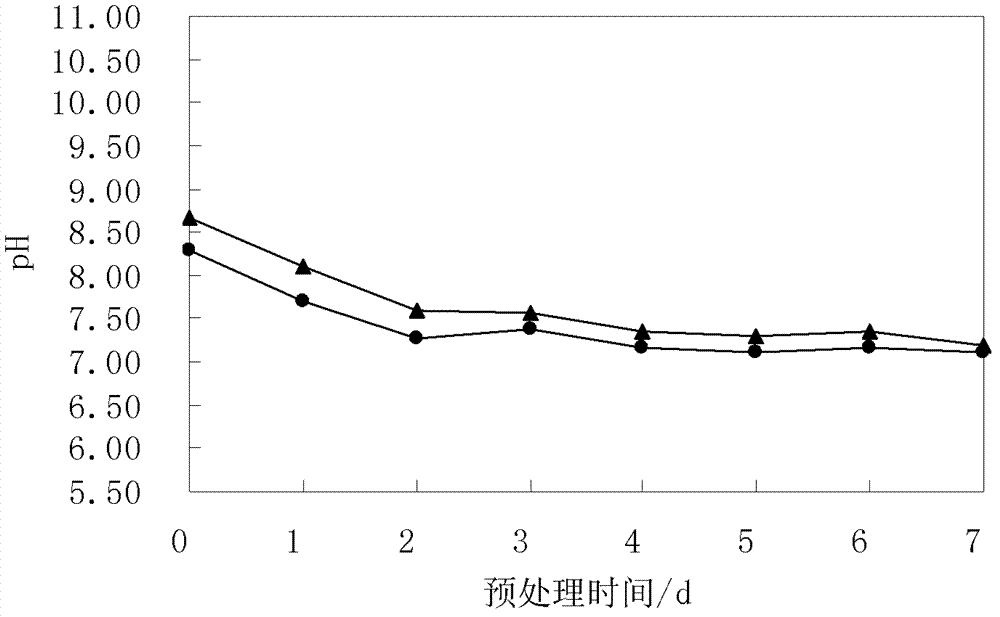

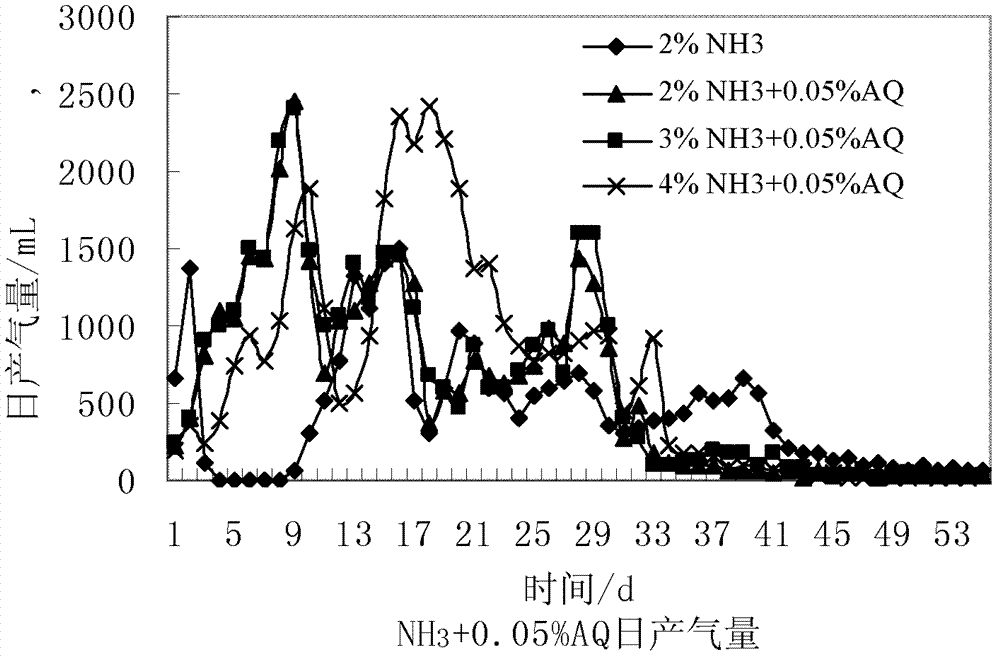

[0032] Take by weighing 3 parts of wheat straw, every part of wheat straw is 97.5g (in TS), account for 2%, 3%, 4% NH of the dry weight of wheat straw respectively 3 ·H 2 O and 0.04875g of anthraquinone (accounting for 0.05% of the dry weight of wheat straw) were mixed, and then 292.5g of water (equivalent to 3 times the water of the dry weight of wheat straw) were added to make NH 3 ·H 2 O and anthraquinone were mixed with each other, sprayed on the chopped wheat straw after uniform mixing, put in a sealed bag, and sealed and stored at 15°C for 4 days.

[0033] Simultaneously with 2% NH 3 ·H 2 O without anthraquinone pretreatment of wheat straw as a control.

[0034] The pretreated raw material is mixed with 200 g (15 g / L in terms of MLSS) inoculum sludge and added to the anaerobic fermentation reactor, and water is added to make the effective volume of the reactor 1.5 L. The reactor was sealed at 35°C for anaerobic reaction for 55 days, and the daily gas production and ...

Embodiment 2

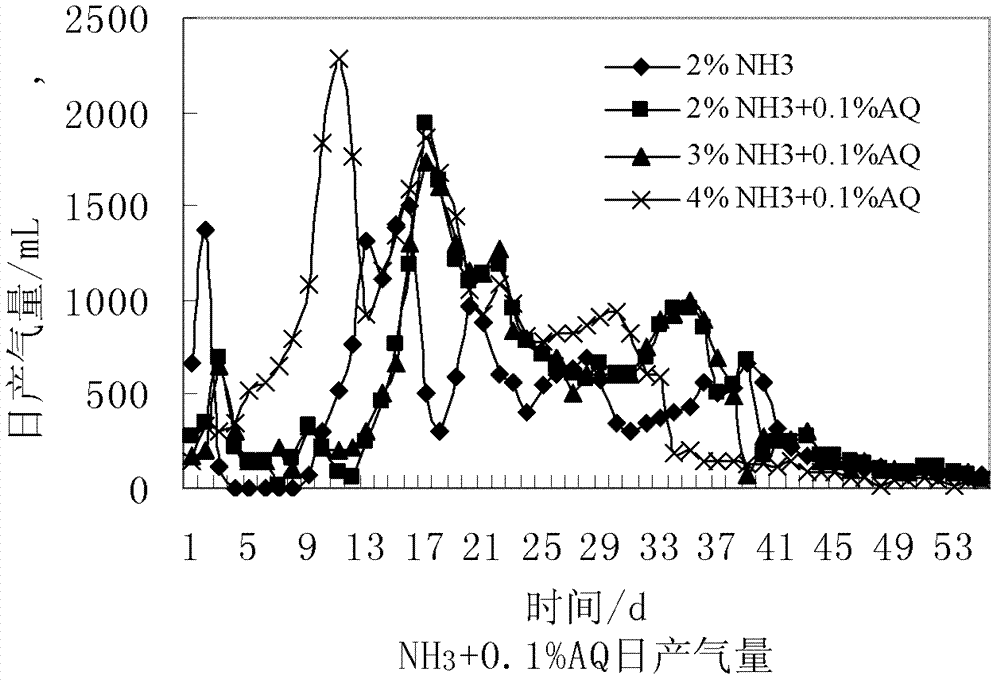

[0039] Take by weighing 3 parts of wheat straw, every part of wheat straw is 97.5g (in TS), account for 2%, 3%, 4% NH of the dry weight of wheat straw respectively 3 ·H 2 O and 0.0975g of anthraquinone (accounting for 0.1% of the dry weight of wheat straw) are mixed, and then add 390g of water (equivalent to 4 times the water of the dry weight of wheat straw) to make NH 3 ·H 2 O and anthraquinone were mixed with each other, sprayed on the chopped wheat straw after uniform mixing, put in a sealed bag, and sealed and stored at 20°C for 4 days.

[0040] Simultaneously with 2% NH 3 ·H 2 O without anthraquinone pretreatment of wheat straw as a control.

[0041] The pretreated raw material is mixed with 200 g (15 g / L in terms of MLSS) inoculum sludge and added to the anaerobic fermentation reactor, and water is added to make the effective volume of the reactor 1.5 L. The reactor was sealed at 35°C for anaerobic reaction for 55 days, and the daily gas production and methane conten...

Embodiment 3

[0046] Take by weighing 3 parts of wheat straw, every part of wheat straw is 97.5g (in TS), will account for 9%, 13.5%, 18% of NH 4 HCO 3 Mix with 0.04875g anthraquinone (accounting for 0.05% of dry weight of wheat straw), then add 487.5g water (equivalent to 5 times of water of dry weight of wheat straw) to make NH 4 HCO 3 Mix with anthraquinone, mix evenly, spray on the chopped wheat straw respectively, put in a sealed bag, and store in a sealed bag at 25°C for 4 days.

[0047] Simultaneously with 2% NH 3 ·H 2 O without anthraquinone pretreatment of wheat straw as a control.

[0048] The pretreated raw material is mixed with 200 g (15 g / L in terms of MLSS) inoculum sludge and added to the anaerobic fermentation reactor, and water is added to make the effective volume of the reactor 1.5 L. The reactor was sealed at 35°C for anaerobic reaction for 55 days, and the daily gas production and methane content were measured every day. The results are shown in Figure 4 . Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com