Complex calcium sulfonate grease and method for preparing same

A technology of compound calcium sulfonate and lubricating grease, used in lubricating compositions, petroleum industry, thickeners, etc., can solve the problems of raw material base number requirement, complex production process, high refining temperature, and achieve water-spray resistance. Good, good shear resistance, good pumping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The production method of composite calcium sulfonate base lubricating grease of the present invention adopts following processing steps: its component ratio is by weight percentage:

[0022] The present invention takes paraffin-based mineral base oil: 32%, vegetable oil: 30%, concentrated sulfuric acid: 20%, calcium hydroxide: 12%, formic acid 3%, conversion accelerator 3% is the composition of calcium sulfonate base lubricating grease of the present invention share.

[0023] Under normal temperature conditions (20-30°C), take 30% of vegetable base oil and 20% of concentrated sulfuric acid, stir and mix for 20-30 minutes, as a spare (1); then take 32% of mineral base oil and 12% of calcium hydroxide, stir and mix Evenly, add 3% special accelerator to the mixed oil, stir for 20-30min, and use it as a spare (2); take the spare (1) and add it to the spare (2), add 3% formic acid, stir, Heating up to 80-110°C, dehydrating, refining, cooling, and homogenizing to obtain the ...

Embodiment 2

[0025] The present invention takes paraffin-based mineral base oil: 35%, vegetable oil: 35%, concentrated sulfuric acid: 13%, calcium hydroxide: 12%, boric acid 2%, conversion accelerator 3% to be the composition of calcium sulfonate base lubricating grease of the present invention share.

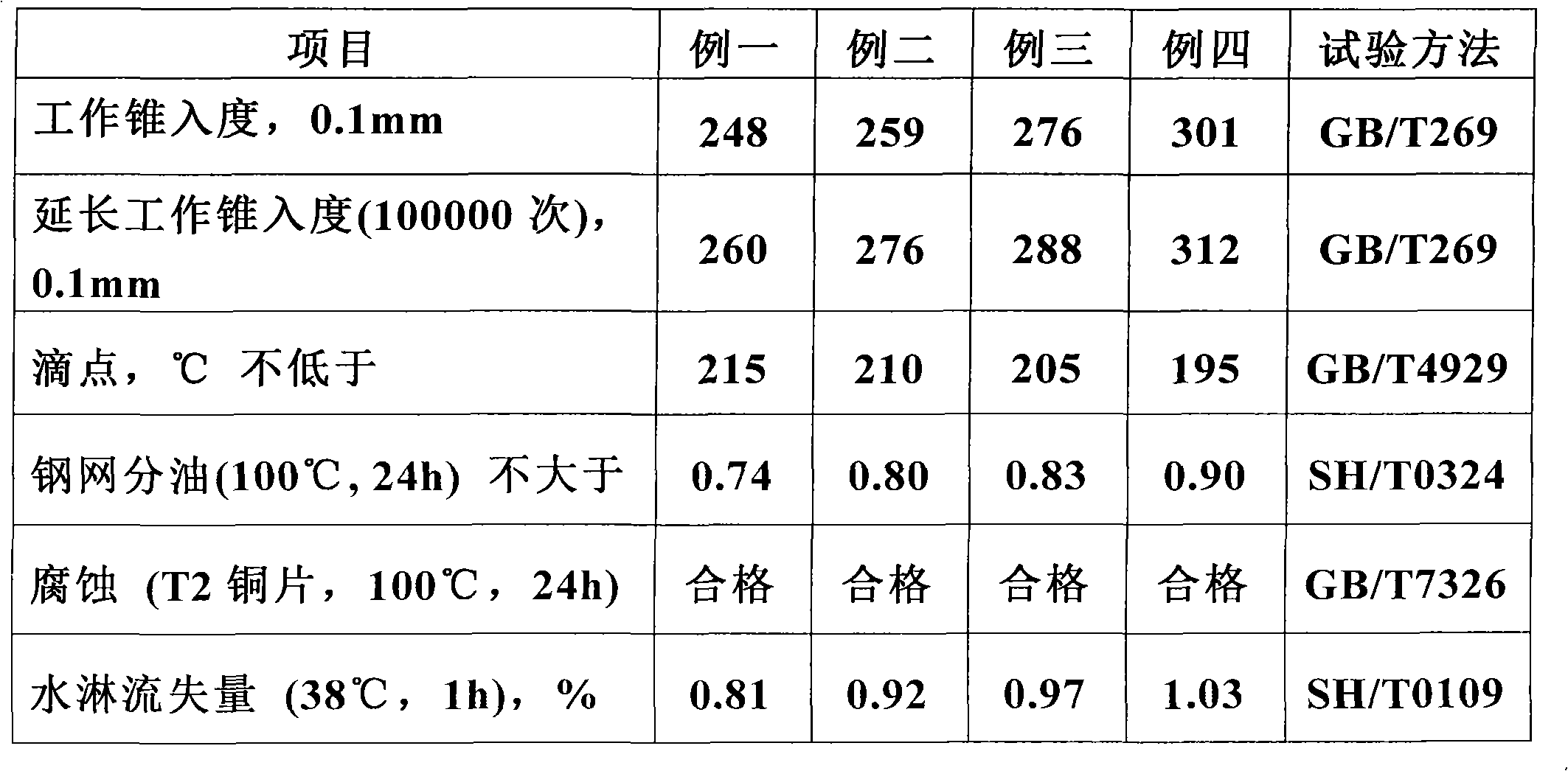

[0026] Under normal temperature conditions (20-30°C), take 35% of vegetable base oil and 13% of concentrated sulfuric acid and stir and mix for 20-30 minutes as a spare (1); then take 35% of mineral base oil and 12% of calcium hydroxide and stir and mix evenly , then add 3% conversion accelerator to the mixed oil product, stir for 20-30min, as spare product (2); take spare product (1) and join in spare product (2), drop into boric acid 2%, stir, heat up to 80-110°C, dehydrated, refined, cooled, and homogenized to obtain the complex calcium sulfonate-based lubricating grease. The physical and chemical performance analysis results of the lubricating grease are shown in Table 1.

Embodiment 3

[0028] The present invention takes paraffin-based mineral base oil: 47%, vegetable oil: 26%, concentrated sulfuric acid: 10%, calcium hydroxide: 10%, glacial acetic acid 4%, conversion accelerator 3% is calcium sulfonate base lubricating grease of the present invention Component.

[0029] Under normal temperature conditions (20-30°C), take 26% of vegetable base oil and 10% of concentrated sulfuric acid and stir and mix for 20-30 minutes as a spare (1); then take 47% of mineral base oil and 10% of calcium hydroxide and stir and mix evenly , then add 3% conversion accelerator to the mixed oil product, stir for 20-30min, as spare product (2); get spare product (1) and join in spare product (2), drop into 4% glacial acetic acid, stir, Heating up to 80-110°C, dehydrating, refining, cooling, and homogenizing to obtain the complex calcium sulfonate-based lubricating grease. The physical and chemical performance analysis results of the lubricating grease are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com