Phase separation conductive high molecular composite material

A technology of conductive polymer and composite material, applied in the field of phase-separated conductive polymer composite material

Inactive Publication Date: 2012-07-25

上海聚威新材料股份有限公司

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to solve the problem of how to reduce the amount of conductive filler while maintaining the conductivity of the polymer composite material, and provide a phase-separated conductive polymer composite with less conductive filler material, high PTC strength, and good material processing performance. Material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

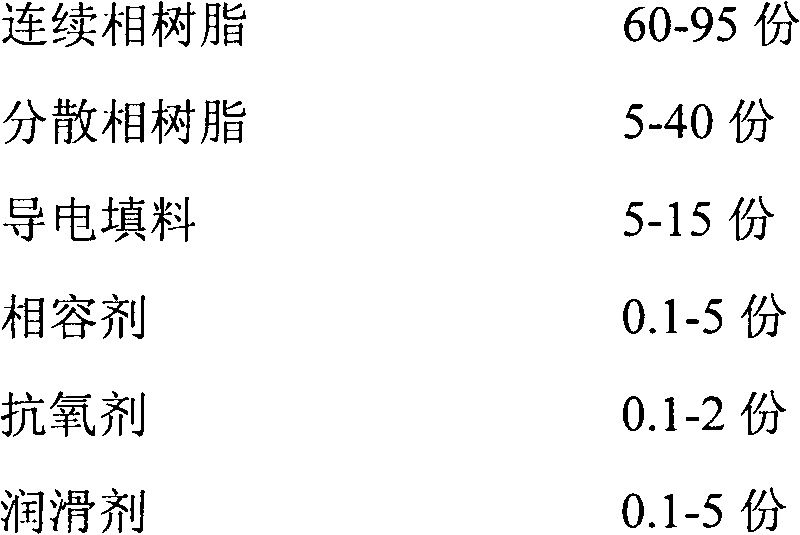

[0025] A phase-separated conductive polymer composite material, consisting of the following substances by weight:

[0026]

Embodiment 2

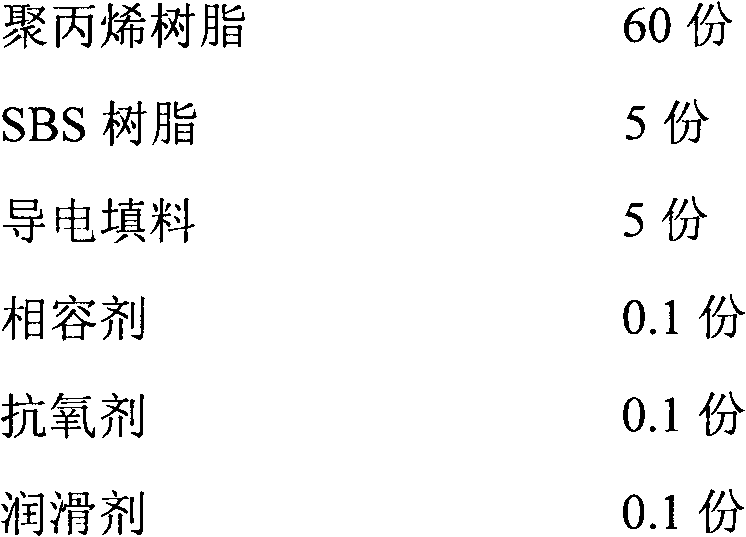

[0028] A phase-separated conductive polymer composite material, consisting of the following substances by weight:

[0029]

Embodiment 3

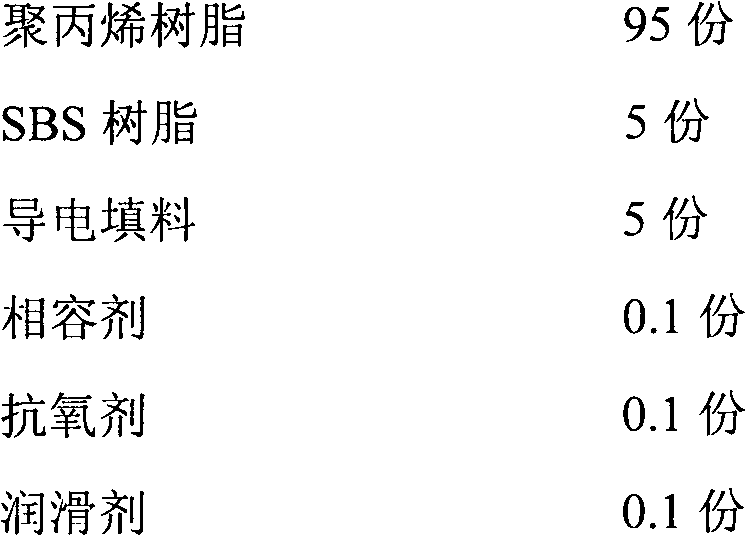

[0031] A phase-separated conductive polymer composite material, consisting of the following substances by weight:

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a phase separation conductive high molecular composite material, which has the composition comprising the following components in parts by weight: 60-95 parts of continuous phase resin, 5-40 parts of dispersed phase resin, 5-15 parts of conductive filler, 0.1-5 parts of compatilizer, 0.1-2 parts of antioxidant and 0.1-5 parts of lubricant. According to component proportioning in the scheme provided by the invention, polypropylene resin forms a continuous phase, SBS (Styrene-Butadiene-Styrene) resin forms a dispersed phase, and meanwhile, the SBS resin forms a conductive path of a continuous network structure in the continuous phase resin of the polypropylene matrix. During preparation, radiation cross-linking is adopted for an extrusion formed product, and further, the repeatability, the stability and the PTC (Positive Temperature Coefficient) strength of the material are improved. According to the phase separation conductive high molecular composite material, the conductive capacity and the PTC strength of the material are kept while the using amount of the conductive filler is reduced; and the material can be used as a superior PTC material.

Description

technical field [0001] The invention relates to the field of composite materials, in particular to a phase-separated conductive polymer composite material. Background technique [0002] Conductive composite materials are composed of polymer materials as the matrix and a certain amount of conductive fillers (such as carbon black, graphite, carbon fiber, metal powder, metal fibers, metal oxides, etc.), which have both the processing characteristics and electrical conductivity of polymer materials. The conductivity of the filler, and its resistance can be adjusted within a wide range. Due to better comprehensive properties, conductive polymer composite materials have a wide range of industrial applications, such as antistatic materials, semiconductor materials, conductive materials, electrothermal materials, and electromagnetic shielding materials. These materials have been widely used in various industries such as electronic communication, energy, and thermal control. Among ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/12C08L53/02C08K13/06C08K9/02C08K3/04B29B9/06B29C35/08

Inventor 王晶王凯张天荣王健李杰

Owner 上海聚威新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com