Device and method for applying an adhesive friction increasing material on an upper surface batch of a stack layer

A static friction and surface technology, which is applied in the stacking, packaging, transportation and packaging of objects, can solve pollution and other problems, and achieve the effects of avoiding pollution, benefiting economy and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

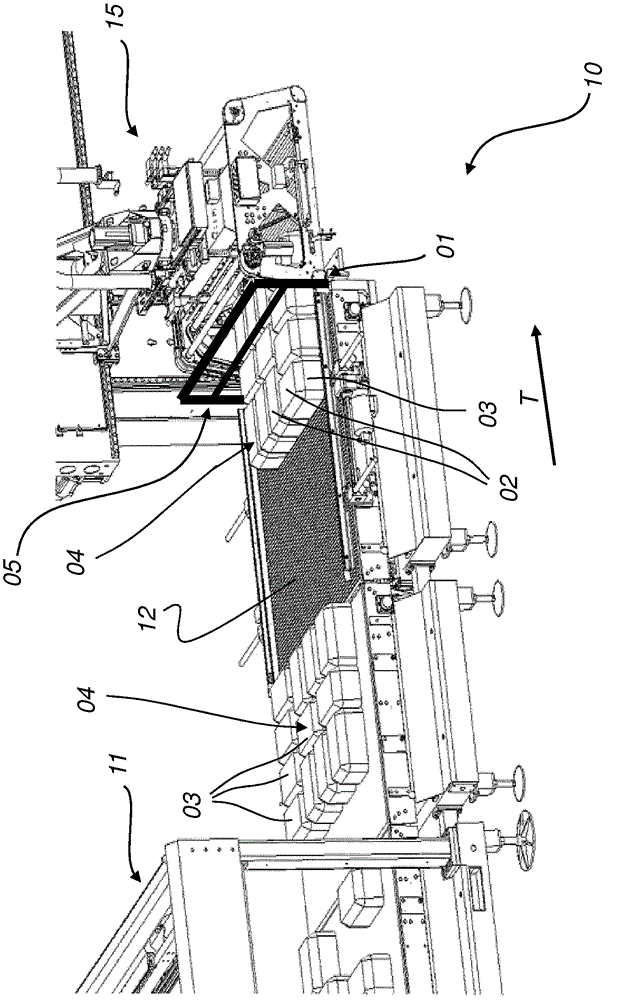

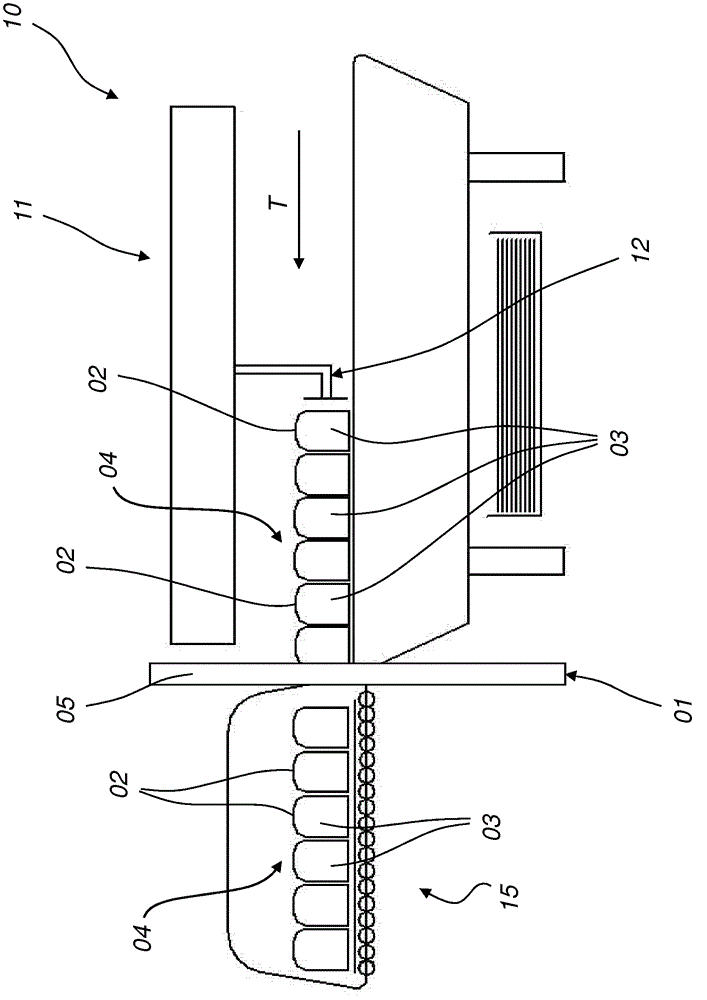

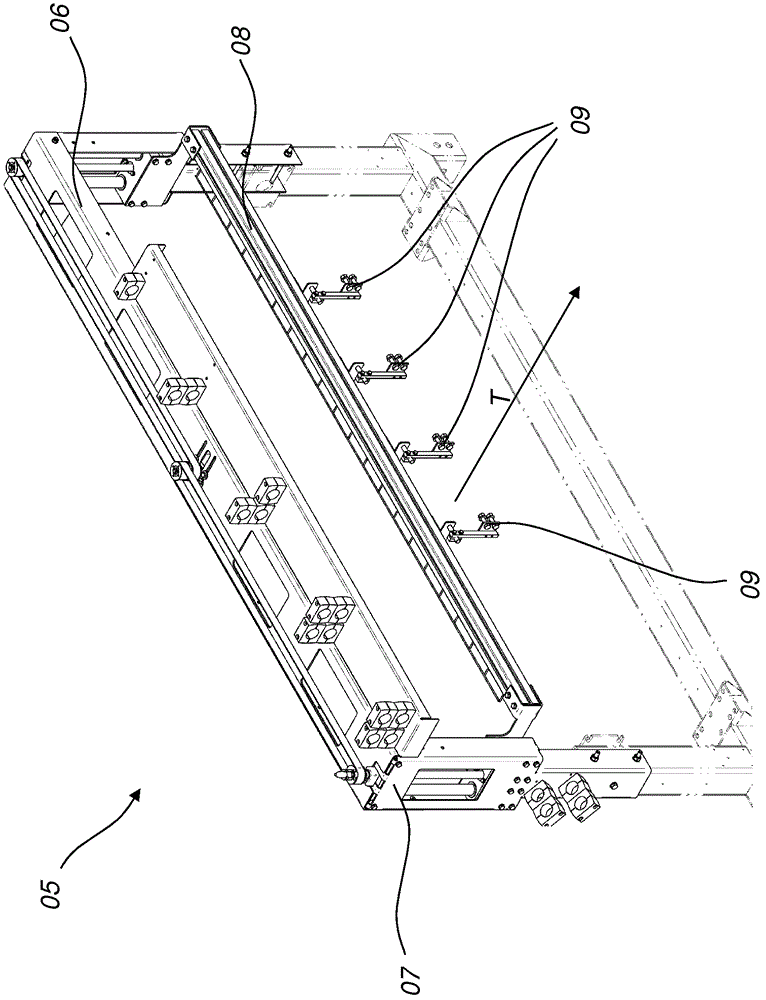

[0055] exist Figure 1 to Figure 3 Device 01 shown in full or in part for applying at least one static friction-increasing medium to at least one surface portion 02 of at least one stacking unit 03 of at least one stacking layer 04 to be stacked into a stack , mainly comprising a nozzle system 05 provided for applying a static friction-increasing medium.

[0056] The nozzle system 05 is preferably arranged or arranged downstream of the workstation 11 for grouping a plurality of stacking units 03 into a stacking layer 04 , and here particularly preferably also for the The stack layer 04 is placed before the appliance 15 on the stack at the storage place. A correspondingly configured device 01 for applying at least one static friction-increasing medium to at least one surface portion 02 of at least one stack unit 03 of at least one stack layer 04 to be stacked into a stack thus comprises A nozzle system 05 for applying a static friction-increasing medium to the surface portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com