CNC (computerized numerical control) lathe

The technology of a numerical control lathe and a numerical control device, which is applied in the field of numerical control lathes, can solve the problem that only one end of a workpiece can be machined, etc., and achieve the effects of easy control and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

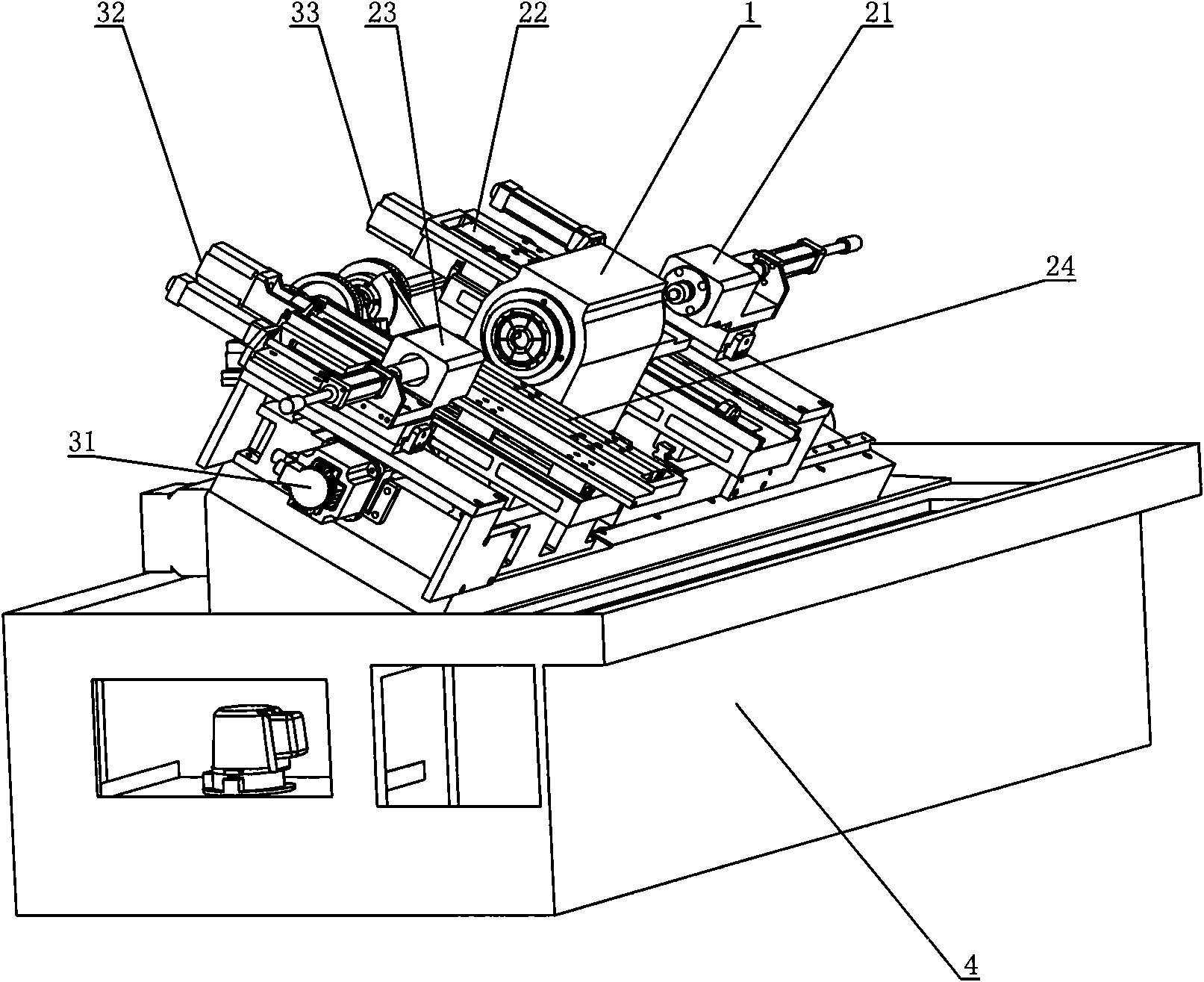

[0037] Such as figure 1 As shown, this embodiment discloses a CNC lathe, which includes: a bed part 4; a headstock device 1 arranged in the middle of the bed 4 for clamping workpieces, and the headstock device 1 adopts a double-ended headstock structure; The sliding device that is made of right top part 21, right slide plate part 22, left top part 23 and left slide plate part 24, right top part 21, right slide plate part 22 are installed on the right side of main shaft device 1, left top part 23, and The left slide part 24 is installed on the left side of the spindle device 1; the tool for processing the workpiece is installed on the left and right slide parts (22, 24), including the tool rest and the tool holder; the first X-axis servo drive device 31, the second A Y-axis servo driver 32, a second X-axis servo driver 33, and a second Y-axis servo driver (not shown in the figure, it has the same function as the first Y-axis servo driver 32 and is symmetrical in position) const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com