Laser processing method of carbon-coated metal micro-powder

A technology of metal micropowder and laser processing, applied in coatings and other directions, can solve the problem of less research on micron-scale powder carbon coating, and achieve the effect of improving application, low cost, and improving anti-oxidation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Disperse 0.1g of Ni micropowder in 10mL of ethanol, take 1mL and place it in a quartz tube with a diameter of 11mm. Under the condition of ultrasonic dispersion, place it under the parallel laser light.

[0040] Among them: when the laser is active, the solution emits a lot of heat, so an ice bath is added during the laser action to reduce the risk of operation through its cooling.

[0041] The finished solution is taken out, and due to the large particle size, the solvent and the powder particles can be separated by natural sedimentation without centrifugation.

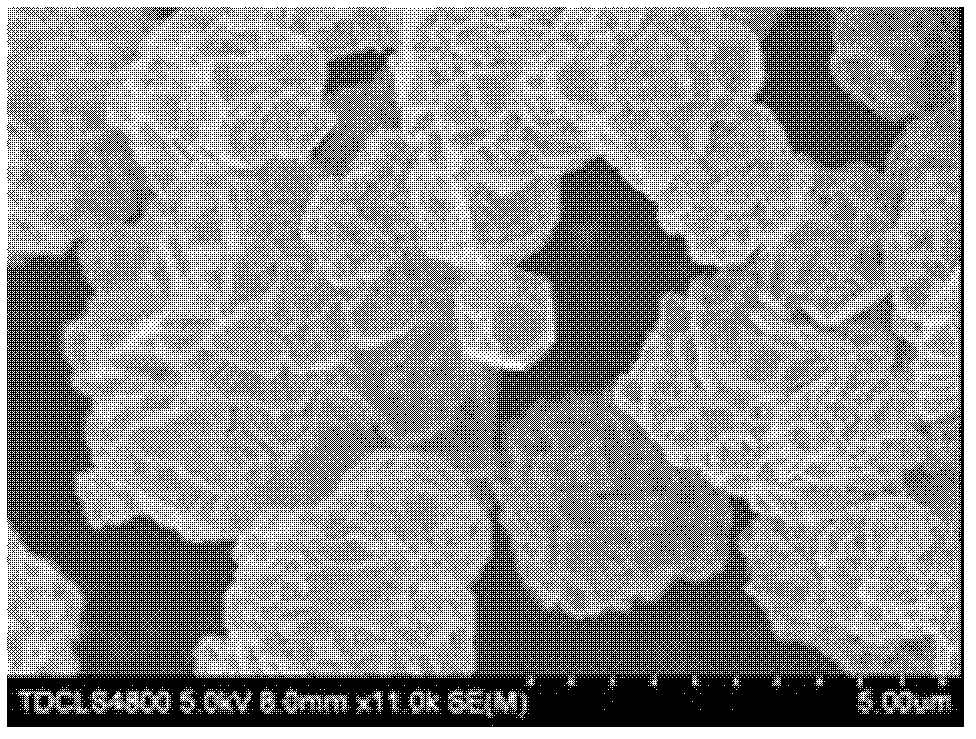

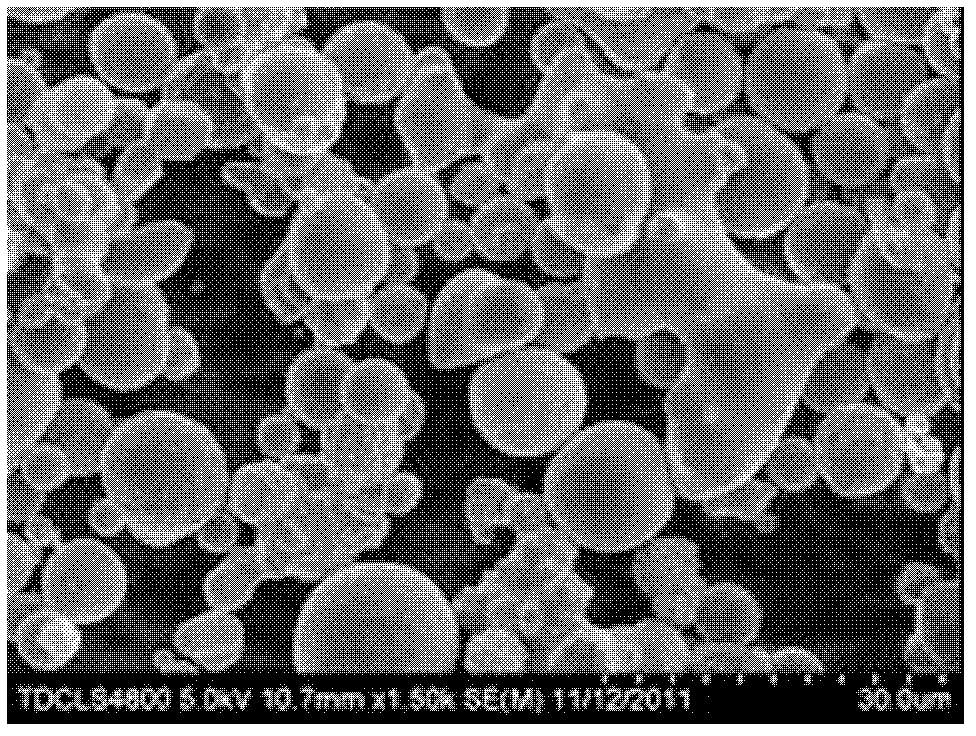

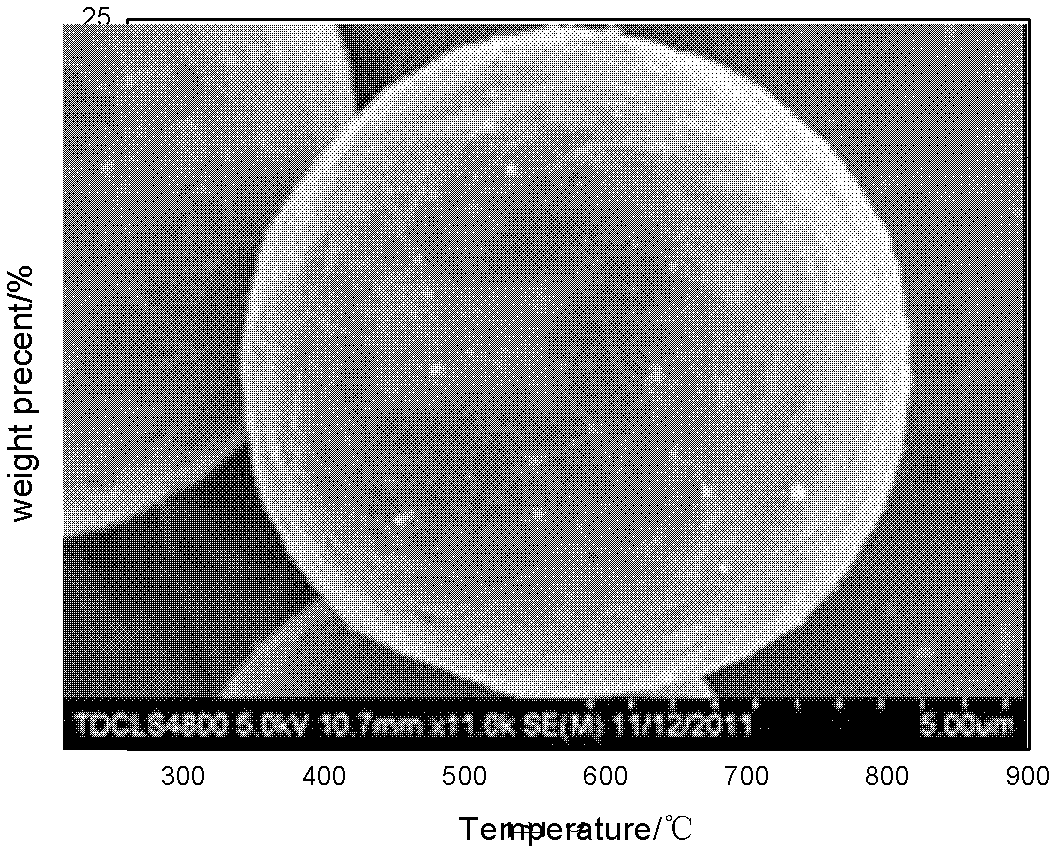

[0042] Depend on figure 1 It can be seen that the morphology of the raw material Ni powder before processing; by figure 2 It can be seen that the morphology of the raw material Ni powder after processing; by image 3 It can be seen that the carbon coating on the surface of a single particle of the raw material Ni powder after treatment.

Embodiment 2

[0044] Disperse 0.1g of Ni micropowder in 15mL of ethanol, take 1mL and place it in a quartz tube with a caliber of 11mm, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0046] Disperse 0.1g of Ni micropowder in 25mL of ethanol, take 1mL and place it in a quartz tube with a caliber of 11mm, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com