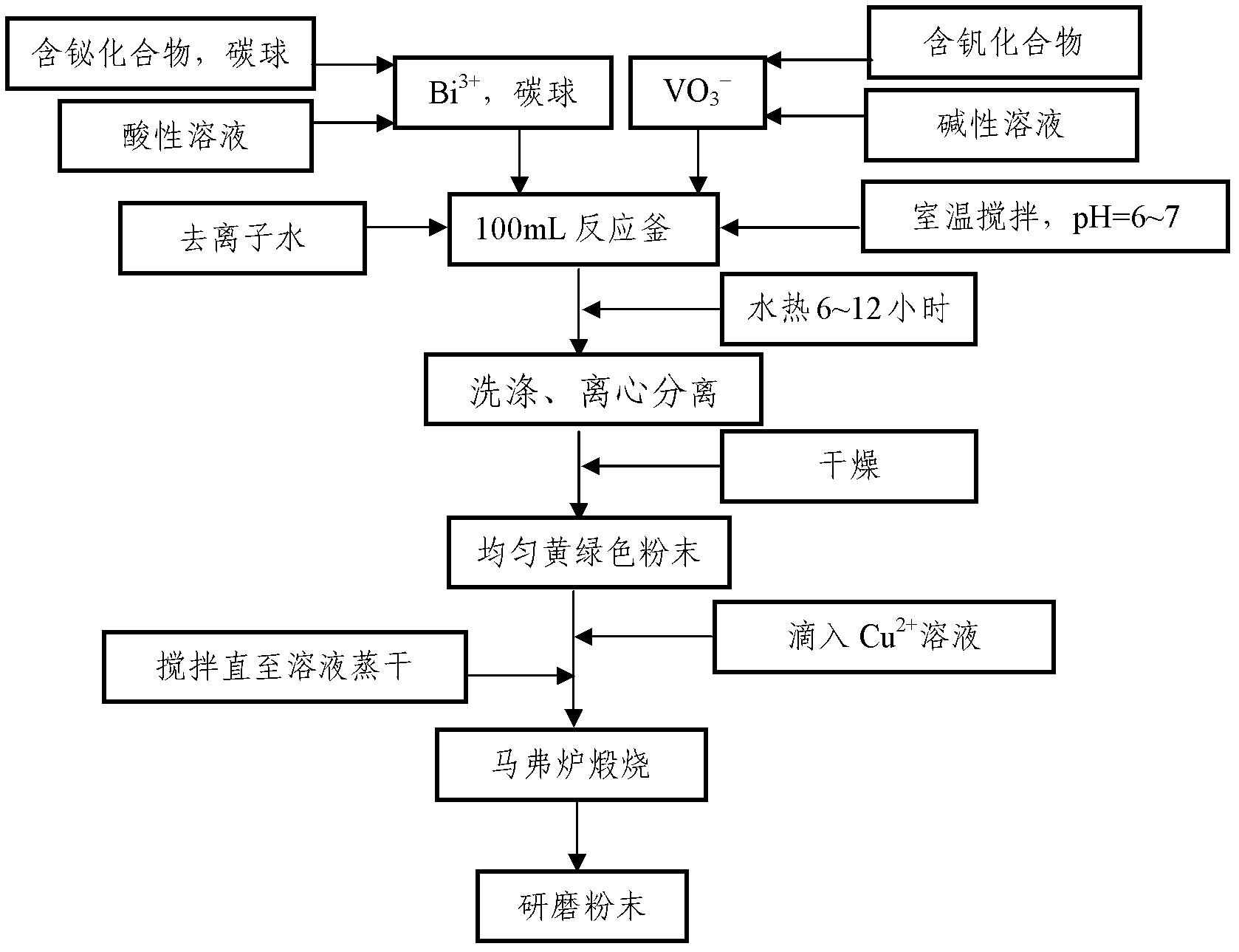

Preparation method of carbon ball-loaded CuO-BiVO4 heterojunction compound photocatalyst

A cuo-bivo4, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of ineffective separation of photogenerated electrons and holes Problems such as easy recombination of flow particles and limited photocatalytic activity, to achieve excellent visible light catalytic activity, adjustable process parameters, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Put 50mL of 0.1mol / L sucrose solution into a 100mL autoclave, heat-treat at 180°C for 10 hours, centrifuge after cooling, wash 3 times with absolute ethanol and deionized water, and dry at 100°C for 12 hours. Carbon spheres are obtained.

[0042] (2) 0.005mol of Bi(NO 3 ) 3 Dissolved in 25mL 4mol / L HNO 3 solution, stirred until completely dissolved, then added 0.015g of carbon spheres, and magnetically stirred for 0.5 hours.

[0043] (3) 0.005mol of NH 4 VO 3 Dissolve in 25mL 4mol / L NaOH solution and stir until completely dissolved.

[0044] (4) Mix the solution obtained in (2) with the solution obtained in (3), adjust the pH of the mixed system to 6, stir it magnetically for 1 hour, transfer it to an autoclave, add 20 mL of deionized water, heat it at 200°C for 6 hours, and cool After centrifugation, the BiVO was prepared after being washed 4 times with absolute ethanol and deionized water, and dried at 70 °C for 24 hours. 4 C catalyst.

[0045] (5) Take 5m...

Embodiment 2

[0048] (1) Put 60mL of 0.3mol / L sucrose solution into a 100mL autoclave, heat-treat at 200°C for 6 hours, centrifuge after cooling, wash 4 times with absolute ethanol and deionized water, and dry at 80°C for 20 hours. Carbon spheres are obtained.

[0049] (2) 0.006mol of BiCl 3 Dissolve in 25mL of 3mol / L HCl solution, stir until completely dissolved, then add 0.09g of carbon spheres, and stir magnetically for 1 hour.

[0050] (3) Add 0.006mol of NaVO 3 Dissolve in 25mL 3mol / L NaOH solution and stir until completely dissolved.

[0051] (4) Mix the solution obtained in (2) with the solution obtained in (3), adjust the pH of the mixed system to 6.5, stir it magnetically for 1.5 hours, transfer it to an autoclave, add 40 mL of deionized water, heat it at 140°C for 12 hours, and cool After centrifugation, washed with absolute ethanol and deionized water three times, and dried at 100 °C for 12 hours, the BiVO 4 C catalyst.

[0052] (5) Take 5mL of 0.01mol / L CuCl 2 solution wit...

Embodiment 3

[0055] (1) Put 90mL of 0.5mol / L sucrose solution into a 100mL autoclave, heat-treat at 140°C for 12 hours, centrifuge after cooling, wash 5 times with absolute ethanol and deionized water, and dry at 70°C for 24 hours. Carbon spheres are obtained.

[0056] (2) 0.005mol of Bi 2 (SO 4 ) 3 Dissolved in 13mL of 2.5mol / L H 2 SO 4 , stirred until completely dissolved, then added 0.3 g of carbon spheres, and stirred magnetically for 2 hours.

[0057] (3) Add 0.01mol of NH 4 VO 3 Dissolve in 13mL of 5mol / L KOH solution and stir until completely dissolved.

[0058] (4) Mix the solution obtained in (2) with the solution obtained in (3), adjust the pH of the mixed system to 7, stir it magnetically for 2 hours, transfer it to an autoclave, add 24 mL of deionized water, heat it at 160°C for 8 hours, and cool After centrifugation, BiVO was prepared after being washed 5 times with absolute ethanol and deionized water, and dried at 80 °C for 18 hours. 4 C catalyst.

[0059] (5) Take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com