Catalyst for use in synthesis of methyl formate and preparation method and application thereof

A methyl formate and catalyst technology, which is applied in the field of catalysts and preparations for the synthesis of methyl formate, can solve the problems of catalyst activity loss, catalyst stability not fundamentally improved, and failure to meet catalyst life requirements, etc., to achieve short process , low energy consumption, and simple separation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

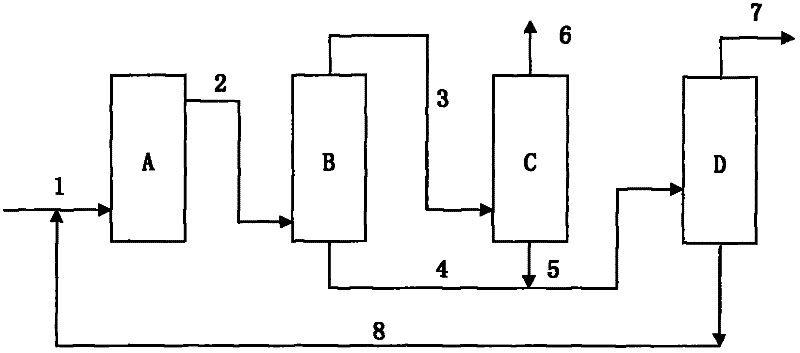

Image

Examples

Embodiment 1

[0049] (1) Catalyst preparation process: Weigh copper nitrate 4.0kg, zirconium oxychloride 64.02kg respectively, namely Cu / Zr=1 / 12 (molar ratio), configure mixed salt solution, and press oxalic acid: copper nitrate=0.01mol / Add oxalic acid to the mixed solution at a ratio of mol, and mix well. Potassium hydroxide was used as the precipitating agent, mixed with the mixed solution for precipitation at 70°C under stirring conditions, and then aged for 1 hour. Repeatedly, filter and wash the obtained precipitate to remove soluble heteroions. The resulting filter cake was dried at 60°C for 48h and calcined at 700°C for 1h. Add 0.17kg of potassium bicarbonate to the obtained sample, carefully grind it evenly, and then roast at 450°C for 3 hours to obtain the final catalyst. The catalyst composition (molar ratio) is: Cu / Zr / K=1 / 12 / 0.1.

[0050] (2) Methanol dehydrogenation reaction to generate methyl formate: After molding the catalyst obtained above, it was packed in a fixed-bed r...

Embodiment 2

[0053] (1) Catalyst preparation process: Weigh copper nitrate 8.0kg, zirconium nitrate 3.37kg respectively, namely Cu / Zr=1 / 0.3 (molar ratio), configure mixed salt solution, and press citric acid: copper nitrate=4.0mol / mol Add citric acid to the mixed solution and mix well. Potassium carbonate was used as the precipitating agent, mixed with the mixed solution for precipitation at 60°C under stirring conditions, and then aged for 3 hours. Repeatedly, filter and wash the obtained precipitate to remove soluble heteroions. The resulting filter cake was dried at 80°C for 36h and calcined at 250°C for 8h. Add 13.73 kg of potassium carbonate to the obtained sample, carefully grind it evenly, and then roast it at 350° C. for 3 hours to obtain the final catalyst. The catalyst composition (molar ratio) is: Cu / Zr / K=1 / 0.3 / 6.0.

[0054] (2) Methanol dehydrogenation reaction to generate methyl formate: after molding the catalyst obtained above, it was packed in a fixed-bed reactor to carr...

Embodiment 3

[0056] (1) Catalyst preparation process: Weigh copper nitrate 8kg, zirconium oxynitrate 6.1kg respectively, namely Cu / Zr=1 / 0.8 (molar ratio), configure mixed salt solution, and press malonic acid: copper nitrate=0.08mol / Add malonic acid to the mixed solution at a ratio of mol, and mix well. Using ammonium bicarbonate as a precipitating agent, mix and precipitate with the mixed solution at 80°C under stirring conditions, and then age for 0.5h. Repeatedly, filter and wash the obtained precipitate to remove soluble heteroions. The resulting filter cake was dried at 90°C for 18h and calcined at 500°C for 2h. Add 8.37 kg of potassium nitrate to the obtained sample, grind it carefully and evenly, and then roast it at 450°C for 3 hours to obtain the final catalyst. The catalyst composition (molar ratio) is: Cu / Zr / K=1 / 0.8 / 5.0.

[0057] (2) Methanol dehydrogenation reaction to generate methyl formate: After molding the catalyst obtained above, it was packed in a fixed-bed reactor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com