Straw modified into strong cation type absorbent and preparation method thereof

A cationic and adsorbent technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of low molecular weight, poor solubility, inactive chemical properties, etc., and achieve the effect of wide sources and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

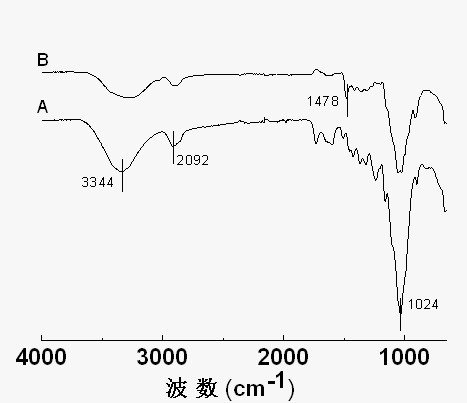

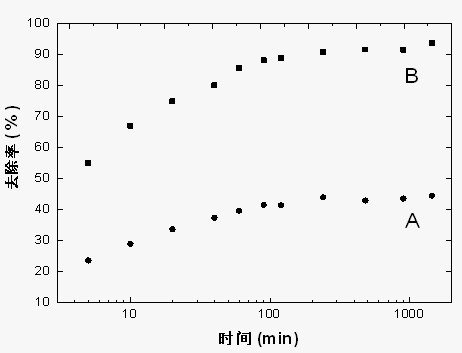

[0027] Disperse the pulverized straw in a mixed solution of isopropanol and sodium hydroxide, wherein the mass percent concentration of sodium hydroxide aqueous solution is 40%, the mass ratio of isopropanol to sodium hydroxide solution is 65:35, the mass of straw The percentage content is 5%, and after stirring for 4 hours of alkalization reaction, the CTA isopropanol solution with a mass percentage concentration of 20% is slowly added dropwise to the alkalized straw solution, and the mass ratio of CTA to straw is 3:1. At 35°C, react for 12 h. Finally, the pH of the above system was adjusted to 6.5 by using an aqueous hydrochloric acid solution with a concentration of 1% by mass. Filter out the straw modified into a strong cationic adsorbent. Infrared spectra of straw and straw modified into strong cationic adsorbent see figure 1 ,from figure 1 (B) See wavenumbers 3344 and 2092nm -1 O-H and C-H characteristic absorption peaks respectively; 1478nm -1 It is the characteris...

Embodiment 2

[0031] Disperse the pulverized straw in a mixed solution of isopropanol and sodium hydroxide, wherein the mass percent concentration of sodium hydroxide aqueous solution is 10%, the mass ratio of isopropanol to sodium hydroxide solution is 15:85, the mass of straw The percentage content is 1%, and after stirring for 1 hour of alkalization reaction, the CTA isopropanol solution with a mass percentage concentration of 1% is slowly added dropwise to the alkalized straw solution, and the mass ratio of CTA to straw is 3:1. At 35°C, react for 12 h. Finally, the pH of the above system was adjusted to 6.5 by using an aqueous hydrochloric acid solution with a concentration of 1% by mass. Filter out the straw modified into a strong cationic adsorbent. The infrared spectra of the straw and the straw modified into a strong cationic adsorbent are the same as in Example 1.

[0032]

Embodiment 3

[0034] Disperse the crushed straw in a mixed solution of isopropanol and sodium hydroxide, wherein the mass percent concentration of sodium hydroxide aqueous solution is 25%, the mass ratio of isopropanol to sodium hydroxide solution is 20:80, the mass of straw The percentage content is 10%, and after stirring for 1 hour of alkalization reaction, the CTA isopropanol solution with a mass percentage concentration of 10% is slowly added dropwise to the alkalized straw solution, and the mass ratio of CTA to straw is 5:1. At 35°C, react for 8 h. Finally, the pH of the above system was adjusted to 5.0 by using an aqueous hydrochloric acid solution with a concentration of 5% by mass. Filter out the straw modified into a strong cationic adsorbent. The infrared spectra of the straw and the straw modified into a strong cationic adsorbent are the same as in Example 1.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com