Defoamer for wet-process phosphoric acid production and production method thereof

A technology of phosphoric acid defoamer and wet-process phosphoric acid, which is applied in the direction of foam dispersion/prevention, can solve the problems of defoamer use experience and effect, and there are not many types of chemical defoamers, and achieve defoaming performance and stability Good, cost-effective, simple production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

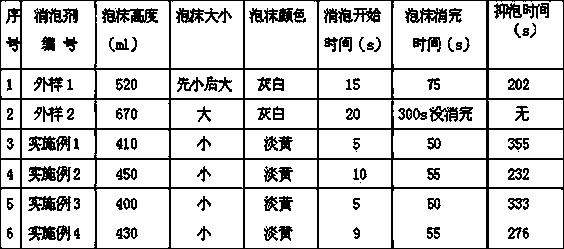

Examples

Embodiment 1

[0030] First, the defoamer active ingredients in proportion by weight: 10 parts of fatty alcohol polyoxyethylene ether, 10 parts of polyoxypropylene glyceryl ether, 10 parts of propylene glycol block polyether L-31 and carboxylate dodecylbenzenesulfonic acid 2 parts, 6 parts of octadecanoic acid are put into the mixing pot for pre-mixing, then add 3 parts of emulsifier S-60, 2 parts of OP-10 and mix thoroughly; under stirring, add 30 parts of carrier base oil (No. 100 base oil) , 23 parts of white oil were put in and mixed uniformly; then 4 parts of potassium dihydrogen phosphate were added and mixed uniformly, and then emulsified by a homogenizer, ground, homogenized, and refined to obtain a defoamer for high-temperature-resistant strong acid wet-process phosphoric acid production.

[0031] The specific method is:

[0032] First put the above ethers and carboxylates into a jacketed mixing pot with stirring, heat up to 80 °C while stirring, then add emulsifier, stir at 80 °C t...

Embodiment 2

[0034] First, the active ingredients of the defoamer in proportion to the weight fraction: 10 parts of polyoxyethylene polyoxypropylene glyceryl ether, 10 parts of polyoxyethylene polyoxypropylene monobutyl ether, 10 parts of propylene glycol block polyether L-61 and carboxylated Put 5 parts of calcium dodecylbenzenesulfonate and 8 parts of isopropyl palmitate into the mixing pot for pre-mixing, then add 4 parts of emulsifier S-80, 1 part of NP-15 and mix thoroughly. Under stirring, the carrier 20 parts of paraffin, 20 parts of white mineral oil, 10 parts of kerosene are put in and mixed evenly; then 2 parts of sodium nitrate are added and mixed evenly, and then emulsified, ground, homogenized and refined by a homogenizer or a colloid mill to obtain a high temperature resistant strong acid Defoamer for wet-process phosphoric acid production.

[0035] The specific method is:

[0036] First put the above ethers and carboxylates into a jacketed mixing pot with stirring, raise t...

Embodiment 3

[0038] First, the defoamer active ingredient in proportion by weight: 20 parts of propylene glycol block polyether L-61, 10 parts of polyoxypropylene glyceryl ether and 5 parts of carboxylated dodecylbenzenesulfonic acid, 11 parts of dehydroabietic acid , put into the mixing pot for pre-mixing, then add 3 parts of emulsifier NP-2, 2 parts of T-80 and stir well, under stirring, put 38 parts of carrier white mineral oil, 10 parts of white oil, mix well; 1 part of ammonium phosphate is mixed evenly, then emulsified, ground, homogenized and refined by a homogenizer or a colloid mill to obtain a defoamer for high temperature resistant strong acid wet-process phosphoric acid production.

[0039] The specific method is:

[0040] First put the above ethers and carboxylates into a jacketed mixing pot with stirring, heat up to 70 °C while stirring, then add emulsifier, stir at 80 °C to 90 °C for 0.5 h, continue to stir at a constant speed Slowly add the carrier composition, mix at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com