Polymer composite core for paper diaper and preparation method of polymer composite core

A polymer and composite core technology, applied in the direction of absorption pads, etc., can solve the problems of uneven distribution, slow absorption, easy lumping, etc., and achieve the effects of saving tree resources, improving absorption effect, and ensuring environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (corresponding to the first technical solution of the present invention above)

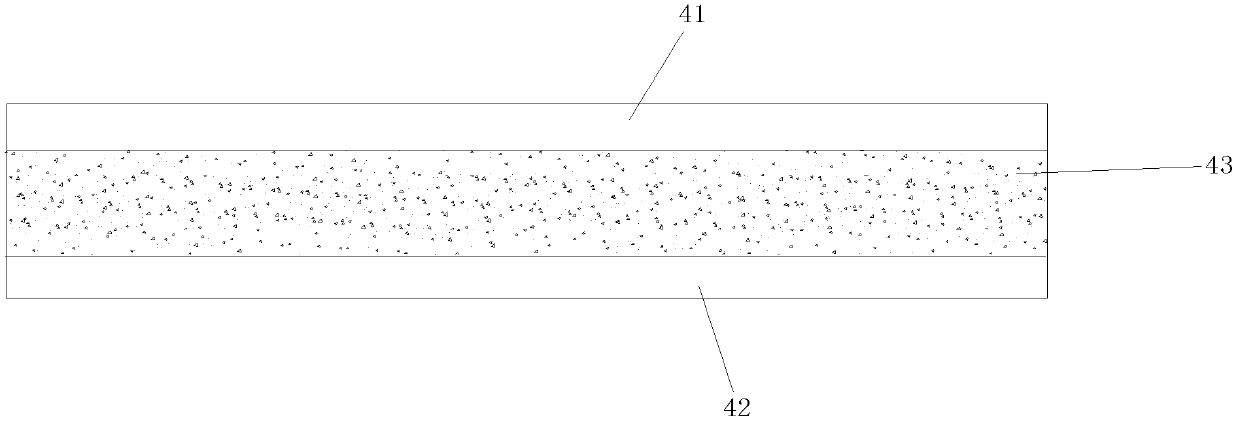

[0034] see figure 1 , the polymer composite core body of the embodiment of the present invention 1 is provided with non-woven surface layer 41, non-woven bottom layer 42 and evenly permeated with polymer water-absorbing resin (SAP) (figure 1 The bulky non-woven fabric intermediate layer 43 shown in the pitting point). The bulky non-woven fabric intermediate layer 43 is a long fiber guide bulky non-woven fabric, and the bulky non-woven fabric intermediate layer 43 is located between the non-woven fabric surface layer 41 and the non-woven fabric bottom layer 42 and is connected with the non-woven fabric surface layer 41 and the non-woven fabric surface layer 41. The bottom layer 42 of non-woven fabric is bonded through thermocompression. The material of the non-woven surface layer 41 and the non-woven bottom layer 42 are non-woven fabrics containing ES fibers. The material of t...

Embodiment 2

[0041] Embodiment 2 (corresponding to the second technical solution of the present invention above)

[0042] see figure 1 , similar to Example 1, the difference is that the bulky non-woven fabric middle layer 43 is connected with the non-woven fabric surface layer 41 and the non-woven fabric bottom layer 42 through an adhesive and through thermal compression.

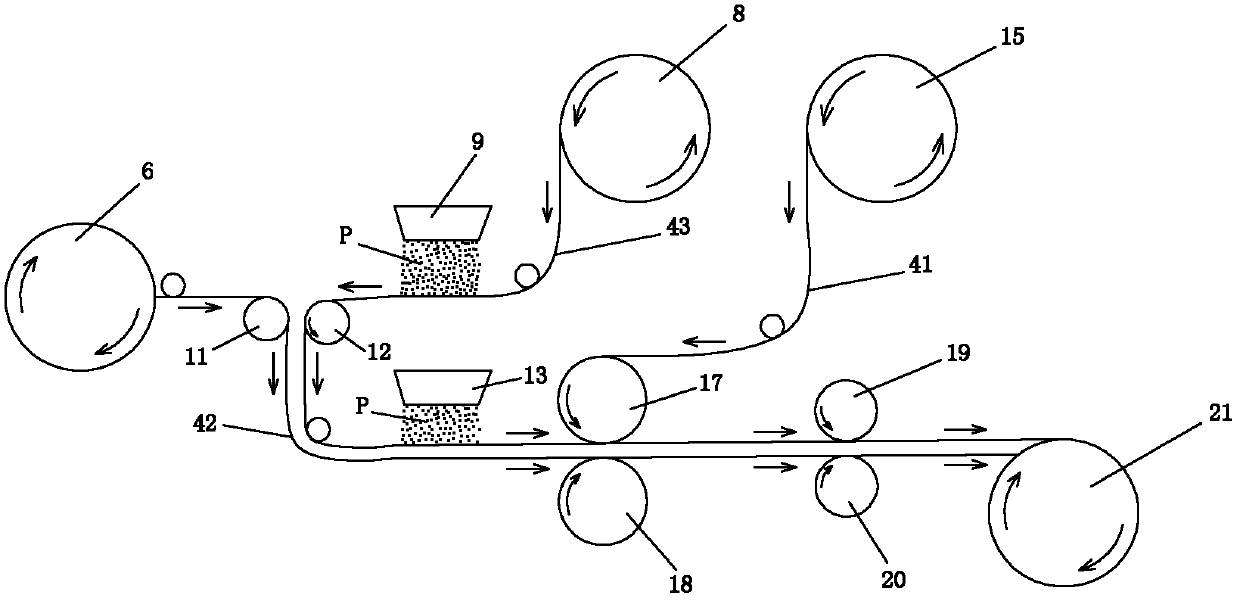

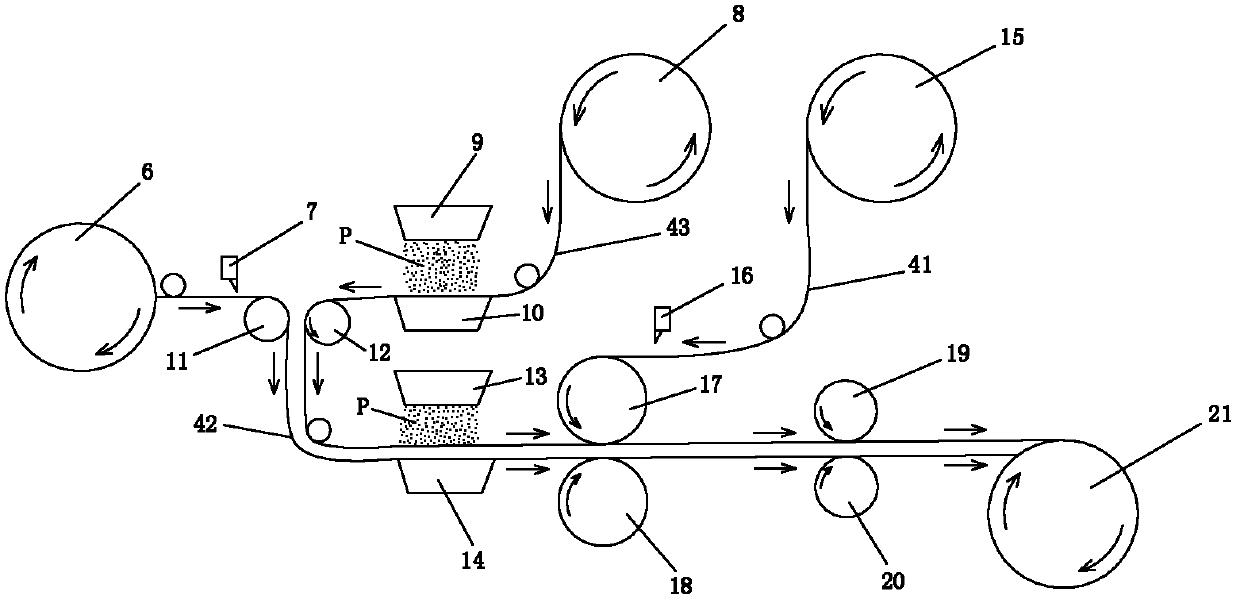

[0043] see image 3 , the preparation equipment of the polymer composite core body described in embodiment 2 is a composite core body machine, and the composite core body machine includes a bottom dust-free paper unwinding reel 6, a bottom dust-free paper glue spray head 7, a bulky non-woven cloth placement Reel 8, front polymer water-absorbent resin sieve plate 9, suction box 10, front heat-pressing roll (including left roll 11 and right roll 12), rear polymer water-absorbent resin sieve plate 13, suction box 14 , surface dust-free paper reel 15, surface dust-free paper glue spray head 16, rear heat pressing roller (...

Embodiment 3

[0048] Embodiment 3 (corresponding to the third technical solution of the present invention above)

[0049] see figure 1 , similar to Example 1, the difference is that the bulky non-woven fabric middle layer 43 is combined with the non-woven fabric surface layer 41 and the non-woven fabric bottom layer 42 through adhesives.

[0050] The polymer composite core described in Example 3 can be prepared using a conventional gluing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com