Bio-enzyme and microorganism containing compound feed additive and preparation process thereof

A technology of compound feed and preparation process, which is applied in the direction of animal feed, animal feed, application, etc., and can solve the problems of reduced effect of additives, affecting feeding effect, and low activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

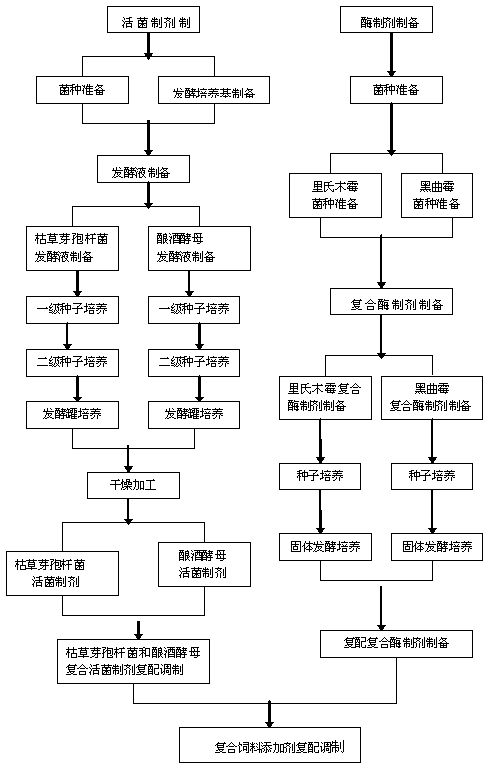

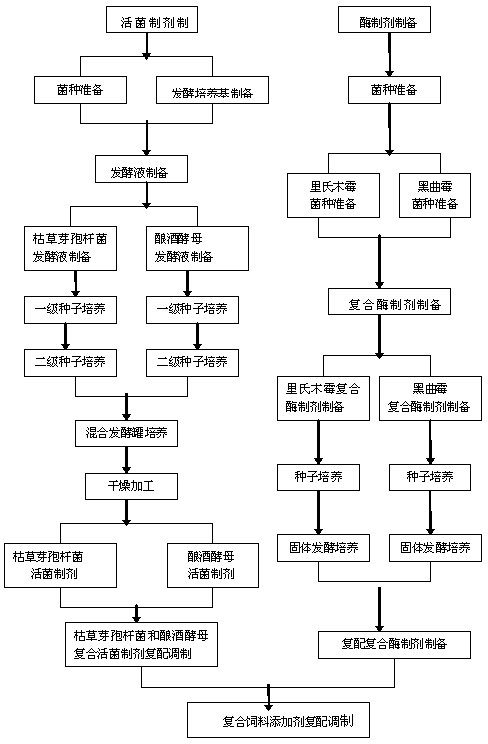

Image

Examples

specific Embodiment approach 1

[0072]The liquid seed after described Bacillus subtilis and Saccharomyces cerevisiae activation is that Bacillus subtilis is inoculated in composition and is 1% peptone, 0.4% beef extract, in the seed culture medium of 0.5%NaCl, 250ml triangular bottle seed culture medium 50ml, take inclined plane The strain 1 loop was inserted into the medium, and cultured on a rotary shaker at 28-32°C, 180-200rpm for 24 hours; inoculated Saccharomyces cerevisiae into the medium composed of Saccharomyces cerevisiae, 50ml of seed medium in a 250ml triangular bottle, and took slant bacteria The first ring of seed is inserted into the culture medium, cultivated for 30 hours at 28-32°C, 180-200rpm on a rotary shaker;

[0073] The activated liquid seeds of Trichoderma reesei and Aspergillus niger were inoculated with Trichoderma reesei and Aspergillus niger in 0.5%CMC, 0.2%NaNO 3 , 0.2%K 2 HPO 4 , 0.05%KCl, 0.05%MgSO 4 ·7H 2 O, 0.0001%FeSO 4 In the culture medium, 50ml of seed medium in 250ml...

specific Embodiment approach 2

[0088] 1.1. Strain preparation

[0089] Bacillus subtilis ( Bacillus subtilis ) and Saccharomyces cerevisiae ( Saccharomyces cerevisiae ) as live bacteria preparation strains;

[0090] 1.2. Fermentation medium preparation

[0091] Choose crushed corn and soybean meal, the ratio of corn and soybean meal is 10:1, add warm water at 40-50°C, the ratio of material to water is 1:2.5-1:3.5, mix well and heat to 75-85°C, The time is 40-50 minutes; cook at 130-135°C, 0.10-0.15MPa for 80-90 minutes, cool to 60-70°C, add high-temperature liquefaction enzyme and glucoamylase for 3-4 hours, and obtain the glucose value (DE value) above 65% and sugar content of 12-14°BX corn and soybean meal enzymatic hydrolysis saccharification solution, adjust the pH value to 4-5, then heat to 90°C for 20-30 minutes, and use it as a fermentation medium;

[0092] 1.3. Fermentation broth preparation

[0093] 1.3.1. Preparation of Bacillus subtilis fermentation broth

[0094] A. Medium

[0095] Seed...

specific Embodiment approach 3

[0142] All experimental groups were reared separately in closed piggery on concrete floor. Put the piglet feed into the feeding trough according to the wet mix (no water in the hand), and feed it 4 times a day at 8:00 in the morning, 12:00 in the afternoon, 16:00 in the afternoon and 20:00 in the evening. Provide sufficient clean drinking water with duckbill drinking fountains, keep the house temperature at 17°C to 25°C, clear the feces twice a day, keep the house clean, and use the same methods for disinfection. During the experiment, piglets were immunized according to routine immunization procedures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com