Liquid detergent composition, and process for production thereof

A technology of cleaning agent and composition, which is applied in the field of liquid cleaning agent composition and its manufacture, can solve the problems of unsatisfactory level and low enzyme stability, and achieve the effect of maintaining storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、3~27、 and comparative example 2、4~7

[0274]

[0275] Into a 50mL beaker, add (B) component of the type and mixing amount (mass %) shown in Tables 1 to 3, and (D) component (D) in an amount (%) 8 times the amount (%) of (B) component, and use a magnetic stirrer to (MITAMURA RIKEN KOGYO INC.), the amount of the solution is about 1cm up from the bottom of the beaker, stir it for 20 minutes with a stirring bar with a length of 25mm and a diameter of 8mm to dissolve it, and then add the types and mixing amounts shown in Tables 1 to 3 (mass %) (C)component is further stirred and pre-mixed to obtain a pre-mix.

[0276] Separately, in a 500 mL beaker, 20.0% of (D) component, 7.0% of alcohol as an optional component, 0.3% of citric acid, 1.0% of MEA, the types and mixing amounts (mass %) shown in Tables 1 to 3 ( A) Ingredients, stir to dissolve these ingredients.

[0277] Next, the pH of the solution at 25° C. was adjusted to 7 with a pH meter (manufactured by Toa Daike Corporation: product name HM-30G) using sodium hy...

Embodiment 2、 and comparative example 1、3

[0280]

[0281] Into a 500mL beaker, add 20.0% of (D) component, 7.0% of alcohol as an optional component, 0.3% of citric acid, 1.0% of MEA, and (A) component of the type and mixing amount (mass %) shown in Tables 1 and 3 And (B) component, stir, and these components are dissolved. .

[0282]Next, with a pH meter (product name HM-30G, manufactured by Toa Daikeke Co., Ltd.), sodium hydroxide and hydrochloric acid were used as pH regulators to adjust the pH of the solution to 7 at 25°C. Then, add the (C) component of the type and mixing amount (mass %) shown in Tables 1 and 3, and stir further, by adjusting the mixing amount of the (D) component, the total amount of the liquid cleaning agent composition of the final product is 100%, thereby obtaining a liquid detergent composition.

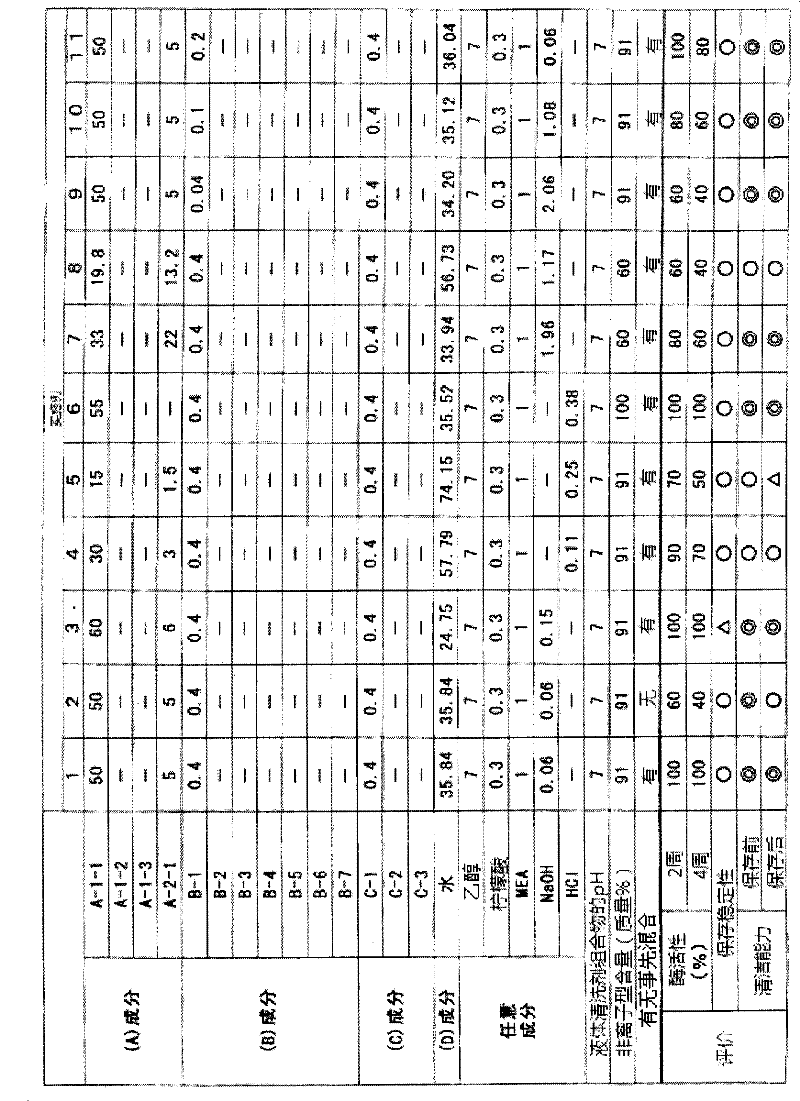

[0283] The obtained liquid cleaning composition was evaluated for enzyme activity, storage stability, and cleaning ability. The results are shown in Tables 1-3.

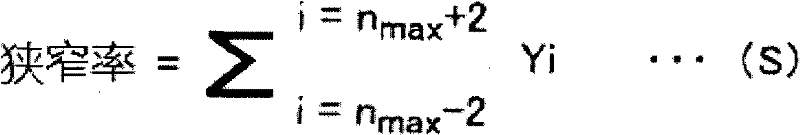

[0284] [Table 1]

[0285] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com