Vector control method for multi-unit drive system based on indirect matrix converter

A matrix converter and multi-machine transmission technology, which is applied in vector control systems, electronic commutation motor control, motor generator control, etc., can solve the problems of limiting the application prospects of multi-machine transmission systems, large volume, short life, etc., to achieve Ensure current quality and speed regulation performance, reduce volume and weight, and reduce switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

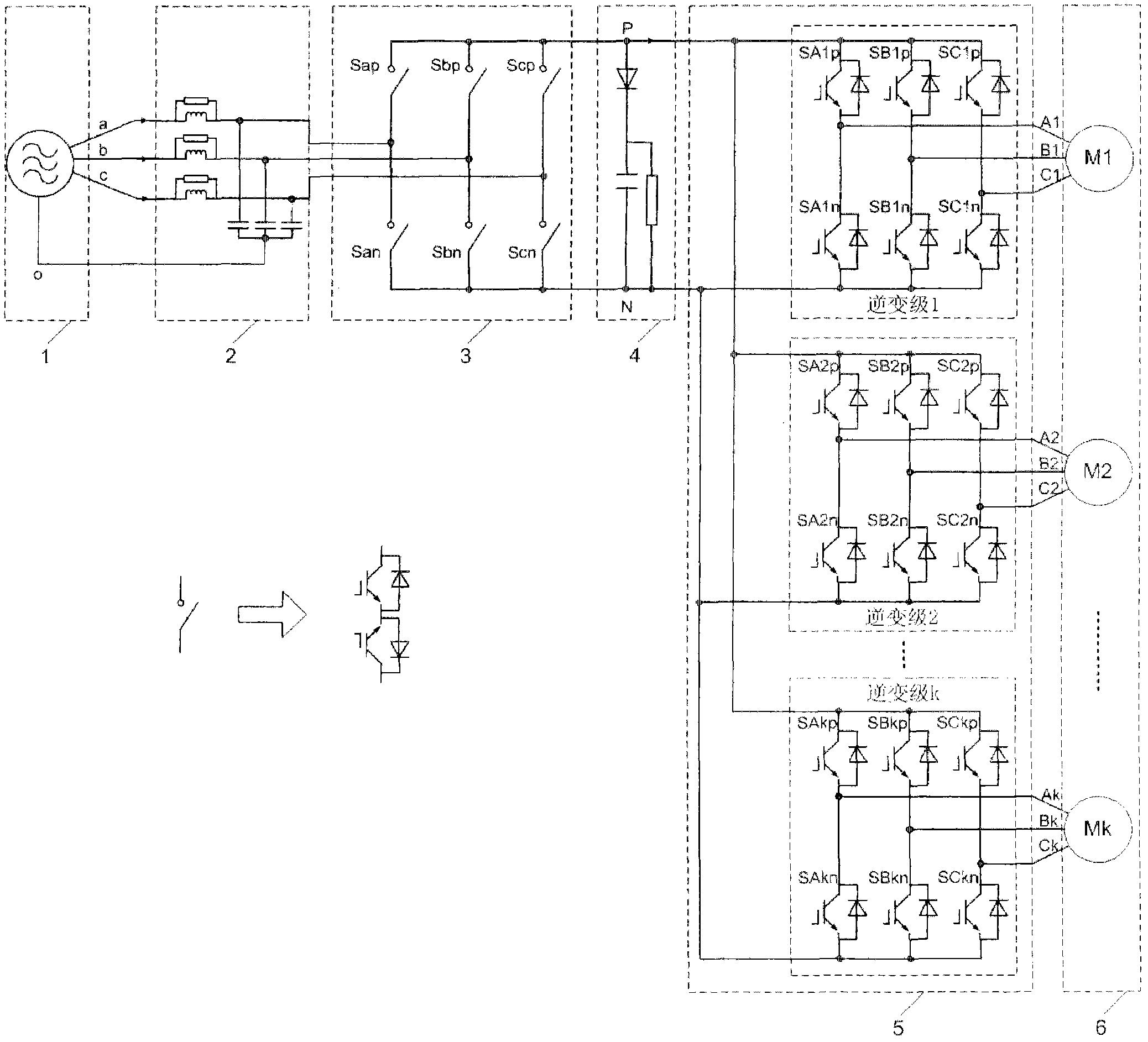

[0019] 1. Multi-machine transmission system topology based on indirect matrix converter

[0020] The main circuit structure of the multi-machine transmission system based on the indirect matrix converter of the present invention is as follows: figure 1 As shown, it includes input three-phase AC power supply (1), input LC filter (2), three-phase bridge rectification stage circuit (3), clamping circuit (4), k three-phase bridge inverter stage circuits ( k is an integer greater than or equal to 2) (5), k asynchronous motors (6) and two DC buses. A three-phase bridge rectifier stage circuit composed of 6 bidirectional switches Sap-Scn (each bidirectional switch is composed of two power switch tubes and two antiparallel diodes in reverse series) 3. A clamp for suppressing voltage spikes Bit circuit 4 and k three-phase bridge inverter stage circuits 5 composed of single-phase switches (SAp-SCn) and freewheeling diodes are sequentially connected to both ends of the DC bus, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com