Non-contact reversing contactor

A non-contact and contactor technology, applied in the direction of motor generator/starter, single multi-phase induction motor starter, electrical components, etc., can solve the problem of affecting production stability, inability to control thyristors, and increasing product scrap rate, etc. problems, to achieve the effect of avoiding phase-to-phase short-circuit faults, reliable interlock function, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

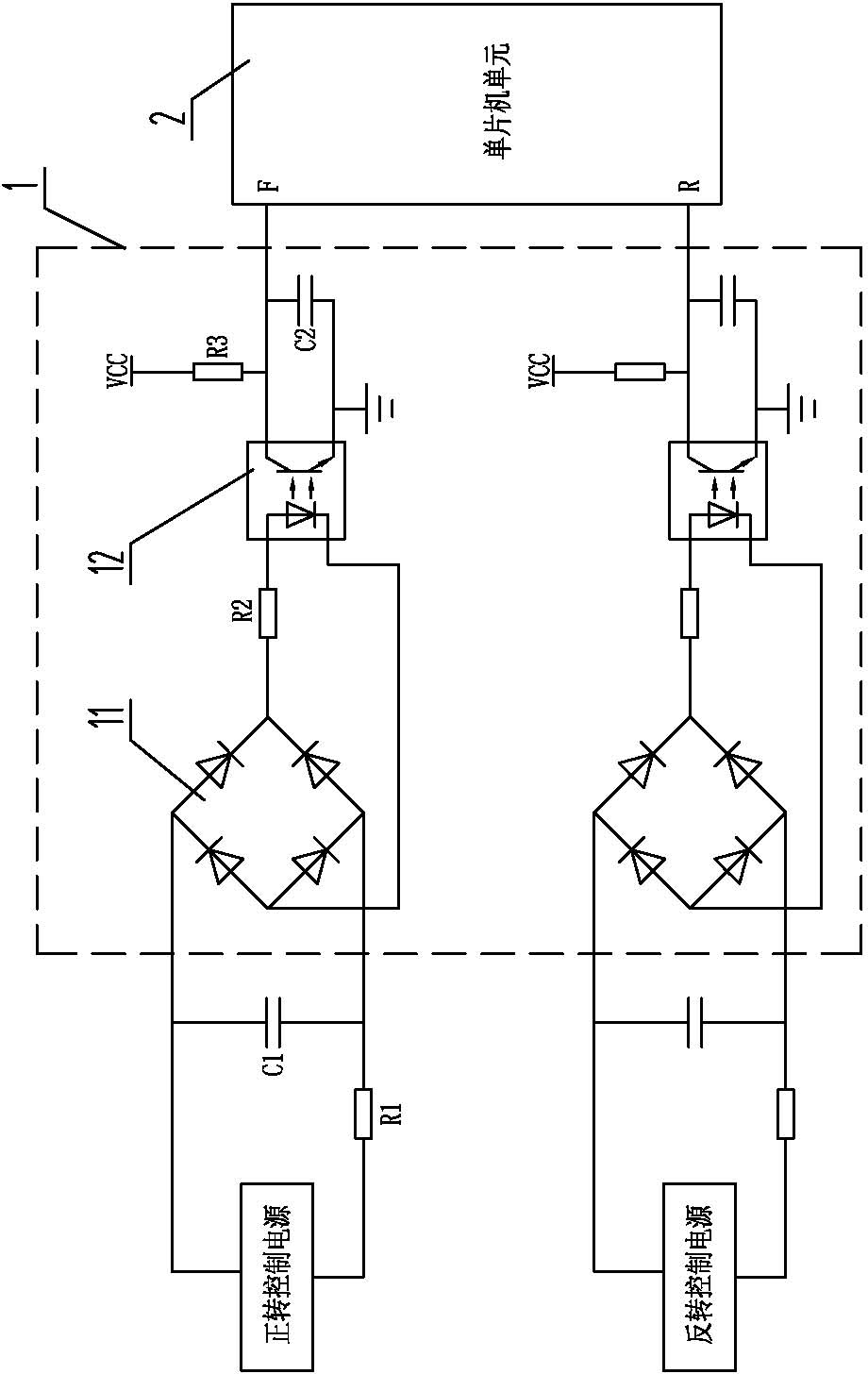

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] Such as figure 1 , 4As shown, in the present invention, the three-phase power supply at the input end is respectively marked as A1, B1 and C1, and the three-phase power supply at the output end is respectively marked as A2, B2 and C2, and five thyristor modules capable of controlling the full-wave conduction of alternating current are arranged in total SCR1, SCR2, SCR3, SCR4, and SCR5. Among them, SCR1 is connected to the A1A2 phase line of the three-phase power supply, SCR2 is connected to the B1B2 phase line of the three-phase power supply, SCR3 is connected to the C1C2 phase line of the three-phase power supply, and SCR4 is connected to the A1C2 phase line of the three-phase power supply. SCR5 is connected to the C1A2 phase line of the three-phase power supply. When the thyristor modules SCR1, SCR2, and SCR3 are turned on,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com