Linear oscillation motor for direct drive pump based on selfshield characteristic of Halbach array

An oscillating motor and self-shielding technology, applied to electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., can solve the problems of reduced effective output force of the motor, low output flow of the pump system, limited power density, etc., to achieve Increased output force, improved dynamic characteristics, and high motor utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

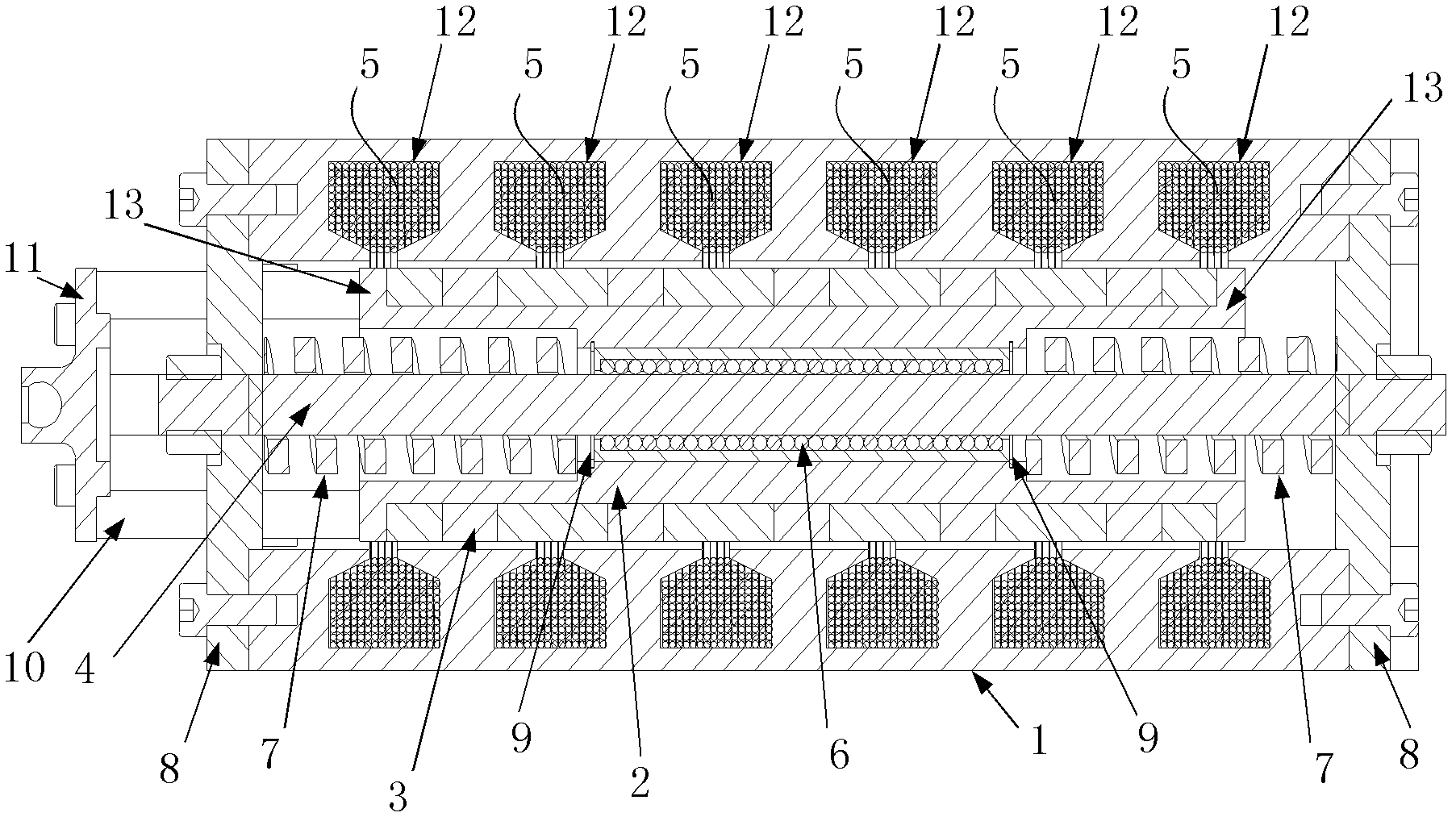

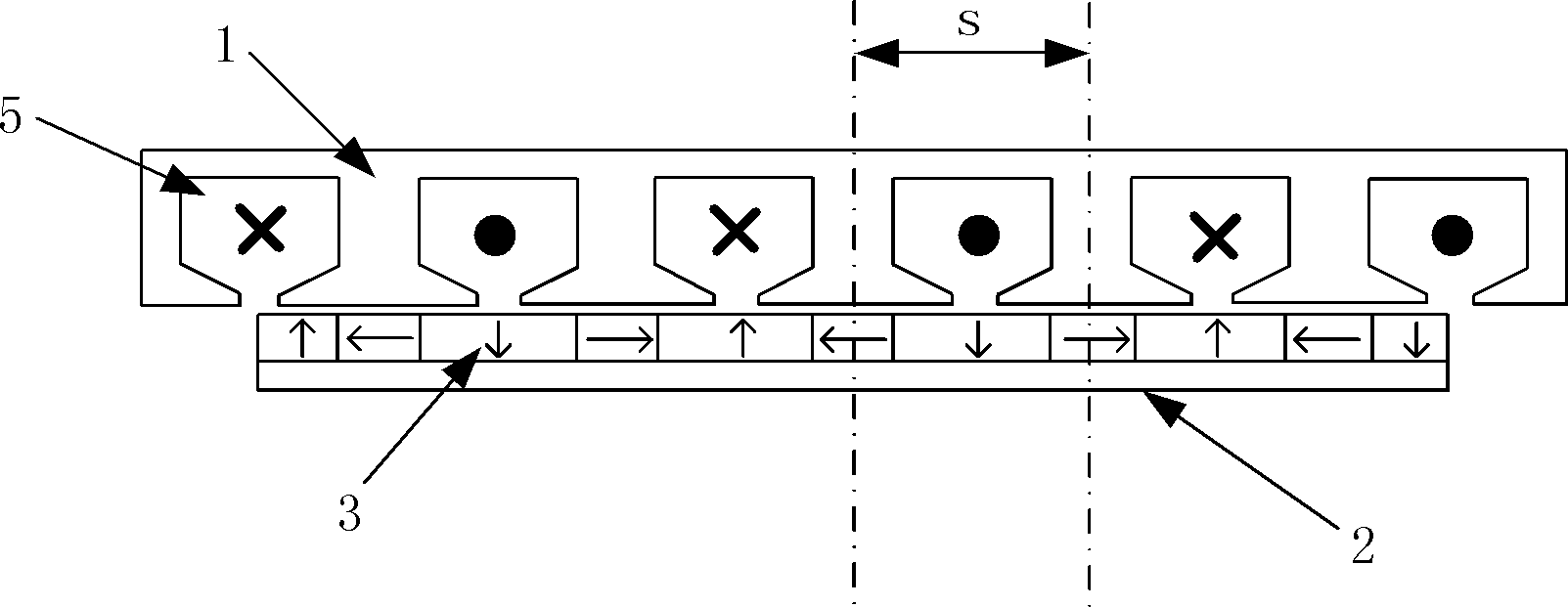

[0031] The linear oscillating motor of the present invention includes an outer layer stator 1 , an inner layer mover 2 , a permanent magnet 3 , a support shaft 4 , a coil winding 5 , a linear bearing 6 , a resonant spring 7 and an end cover 8 .

[0032] Wherein, the outer layer stator 1 is a cylindrical structure. In the present invention, the outer layer stator 1 is designed as a cuboid structure with a cylindrical channel, thereby providing installation and design conditions for the integration of multiple linear oscillating motors in the entire integrated pump. . The inner mover 2 also has a cylindrical structure and is located inside the outer stator 1. Both ends of the inner mover 2 have protruding edges. In the present invention, the outer wall and the outer layer of the inner mover 2 are designed There is an air gap distance of 1mm between the inner walls of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com