SixNy-based resistor-type memory and manufacturing method and application thereof

A resistive and memory technology, applied in the field of microelectronics, can solve the problem that the resistive storage layer is rarely reported, and achieve the effect of high practical value, large storage window, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

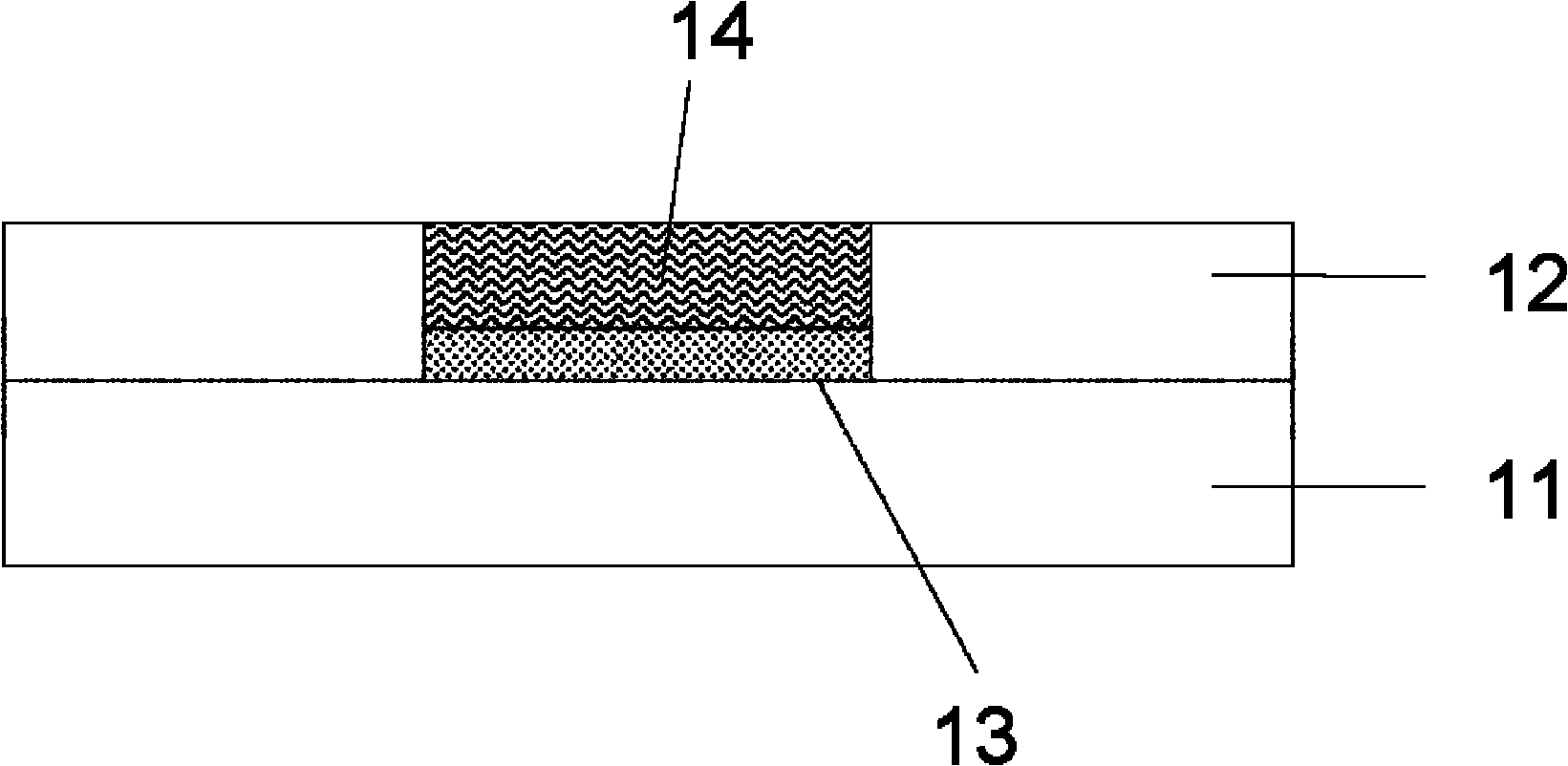

Method used

Image

Examples

Embodiment 1

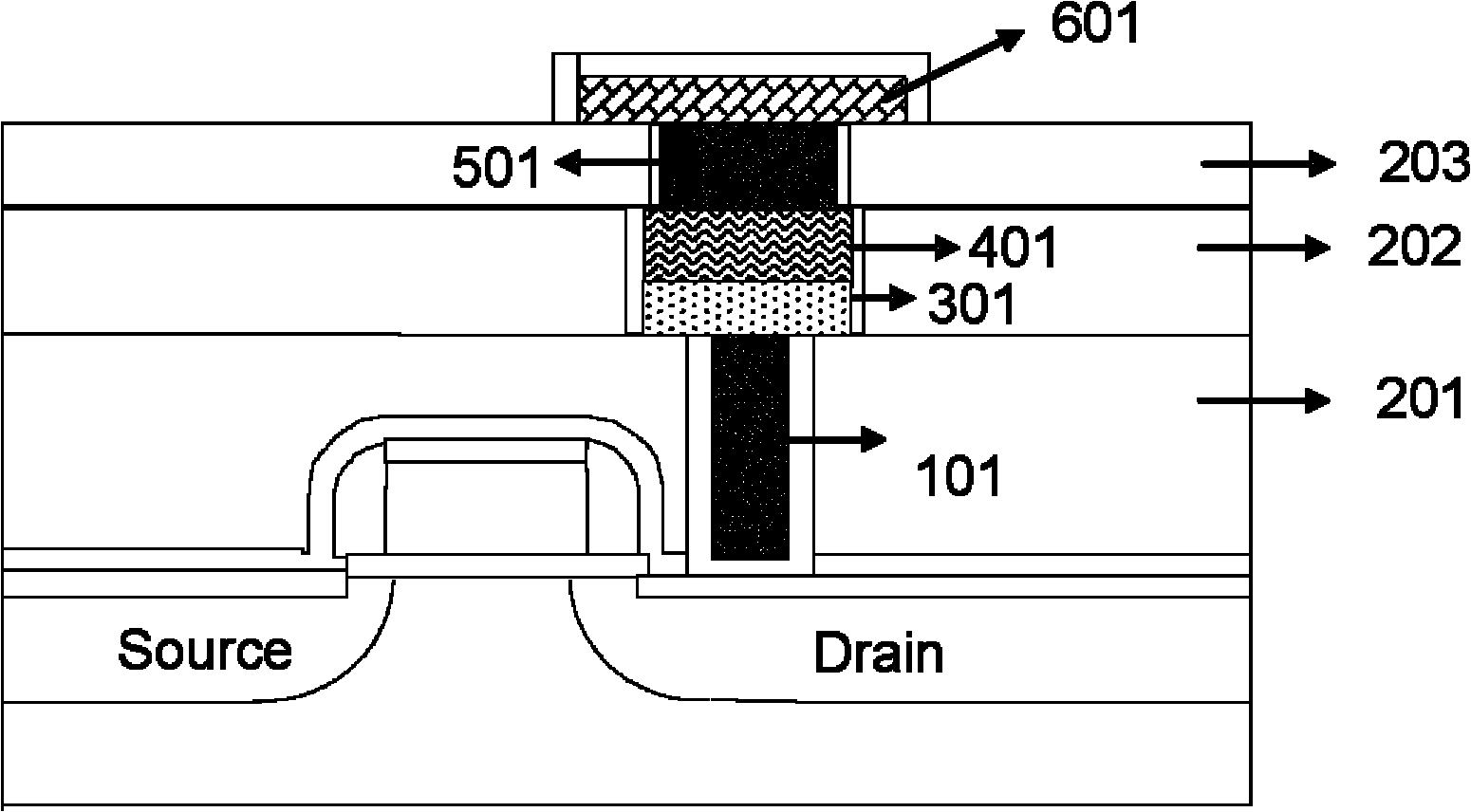

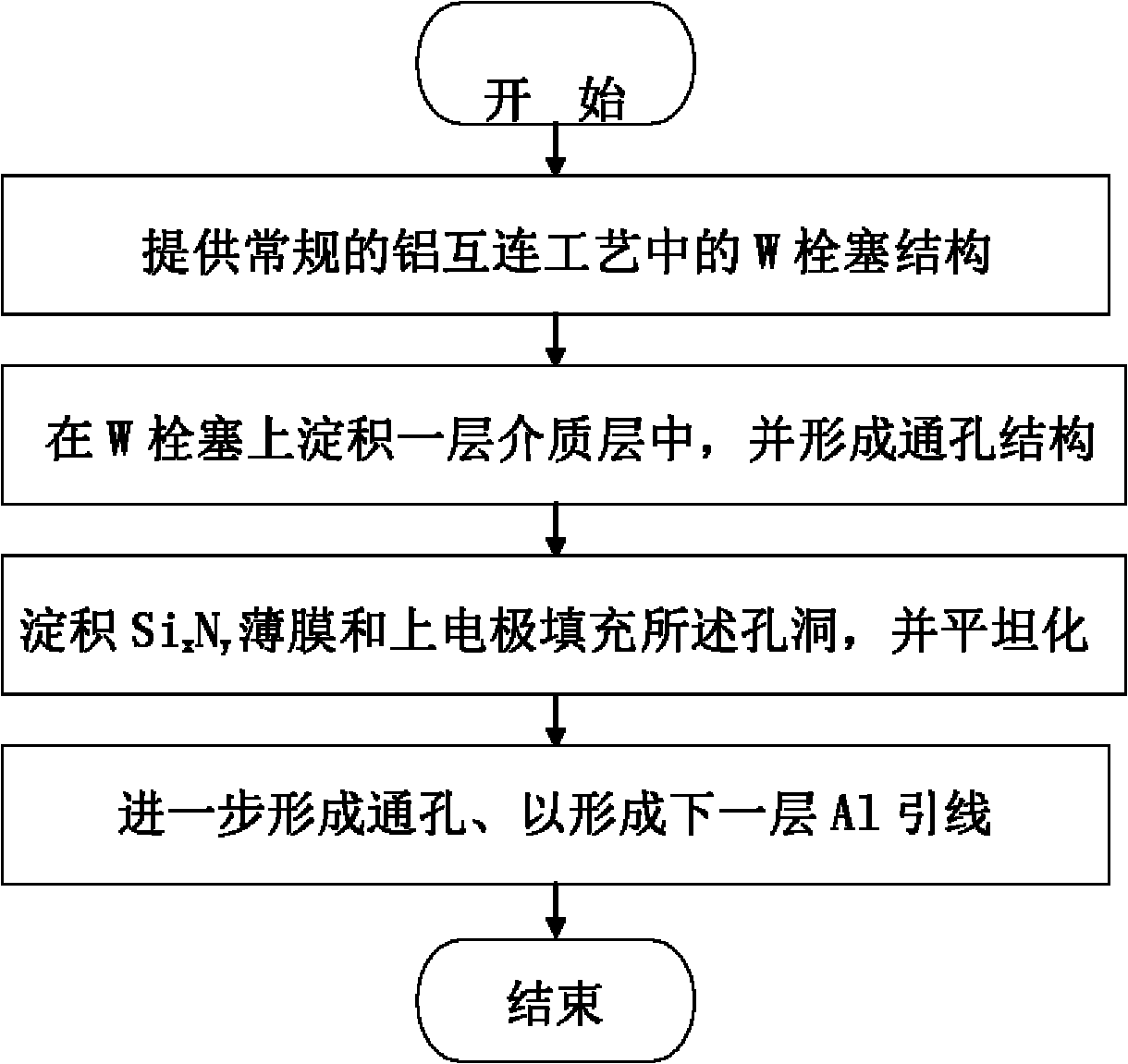

[0038] Embodiment 1: First, deposit a 400nm-thick dielectric layer on the W plug, pattern the dielectric layer, and etch through holes; then, deposit a layer of 20nm-thick Si by PECVD or ALD process. x N y thin film layer, and adjust the Si by controlling the process conditions of PECVD or ALD x N y The chemical composition ratio of the film is such that the Si:N ratio is 2:1; then, a layer of Cu with a thickness of 500 nm is deposited as the upper electrode by magnetron sputtering, and the Cu electrode above the through hole is ground by CMP. Flat, so that the RRAM device structure is completely in the through hole of the dielectric layer; finally, the solder layer, the interconnection metal layer, and the anti-reflection layer are deposited in sequence, and the aluminum lead wiring is patterned by photolithography and etching methods.

[0039] Figure 4 Cu / Si is given x N y / W device current-voltage curve, the device has bipolar resistance transition characteristics in ...

Embodiment 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that Embodiment 2 adopts an ion implantation process to Si x N y The chemical composition ratio of the film is adjusted, and the Ti metal film is used as the upper electrode of the resistive switch device. Figure 5 Ti / Si is given x N y / W current-voltage curve, the device has a unipolar resistance transition characteristic during the voltage sweep. The unipolar switching resistive memory device is beneficial to the integration of 1D1R, and at the same time simplifies the design difficulty of peripheral circuits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com