Method for detecting content of metal ions in methyl alcohol

A technology for metal ions and determination methods, applied in measurement devices, material separation, instruments, etc., can solve the problems of long cycle and long cycle, which is not conducive to multi-component detection of large-scale samples, meet the detection limit requirements, save analysis costs, Ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Raw material: MTO grade methanol sample to be tested

[0055] Prepare the sample to be tested: accurately measure 200ml of MTO grade methanol sample into a 250ml Erlenmeyer flask, place a cap on the top of the Erlenmeyer flask, heat in a water bath at 80°C for 2 hours to obtain a metal ion mixture, and cool to room temperature. Use high-purity water to drip into the Erlenmeyer flask 3 times, each drop 10ml, the metal ion mixture in the Erlenmeyer flask, and clean the metal ion mixture condensed on the cover with the volatilization of methanol vapor, collect the two in a 50ml volumetric flask, High-purity water constant volume to be tested.

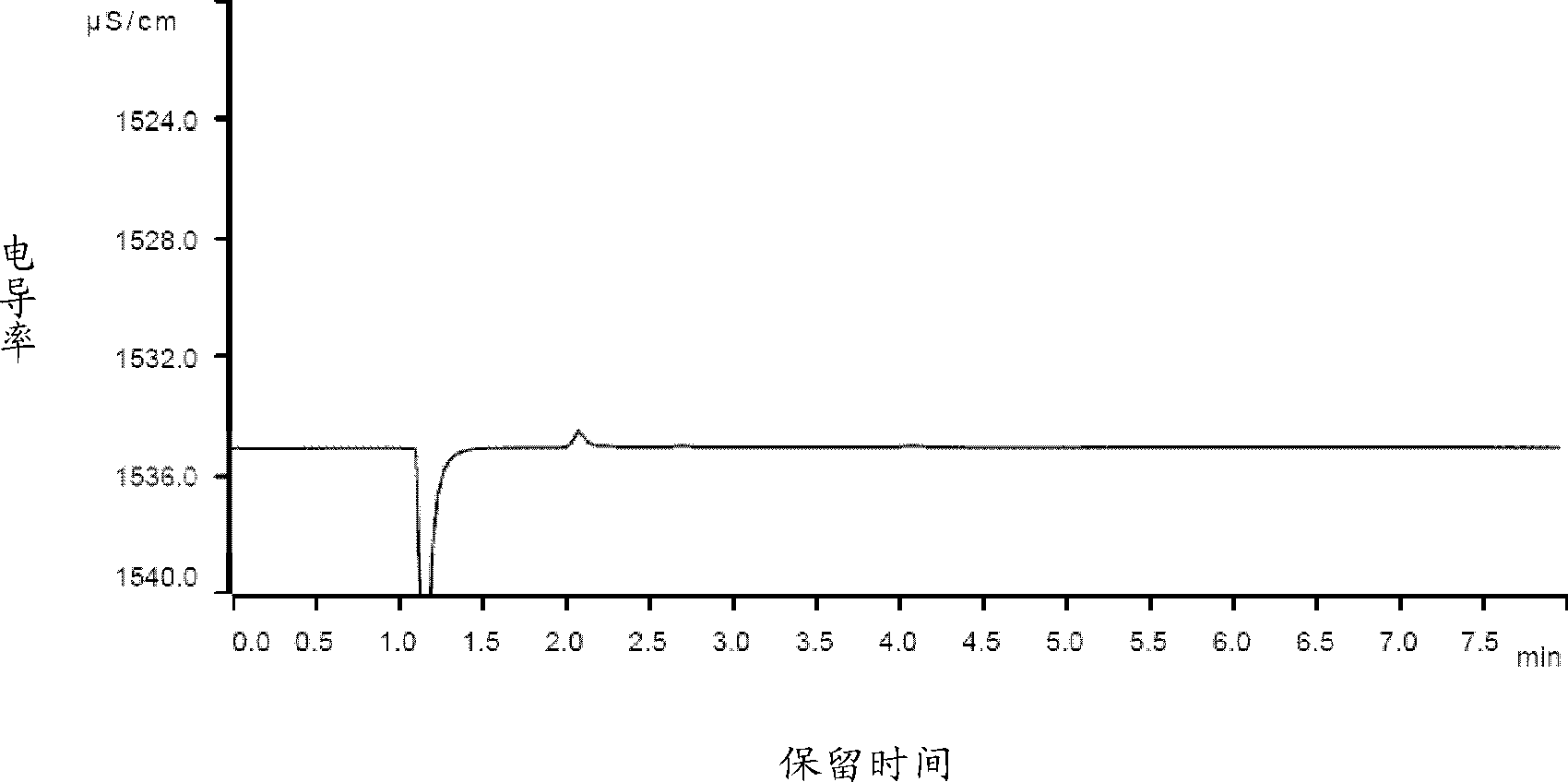

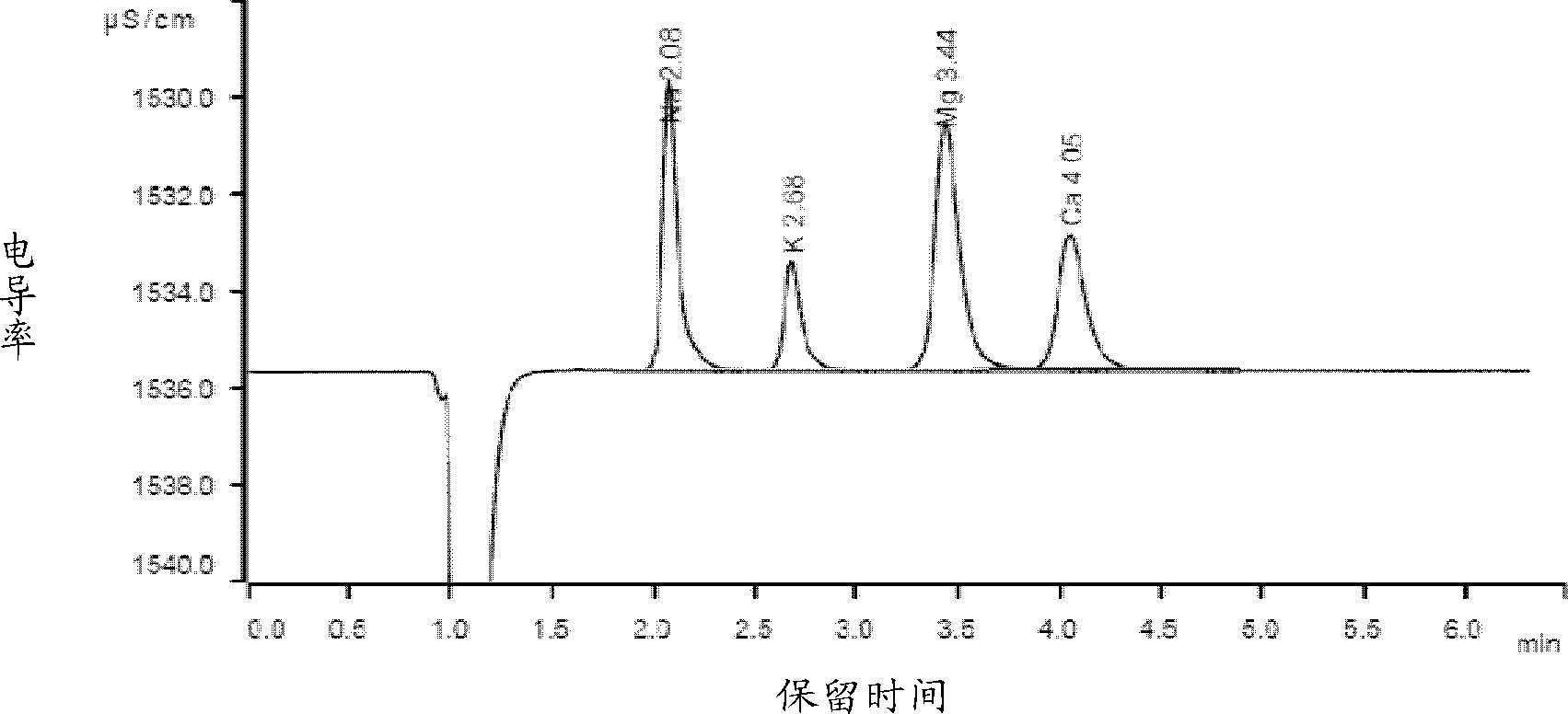

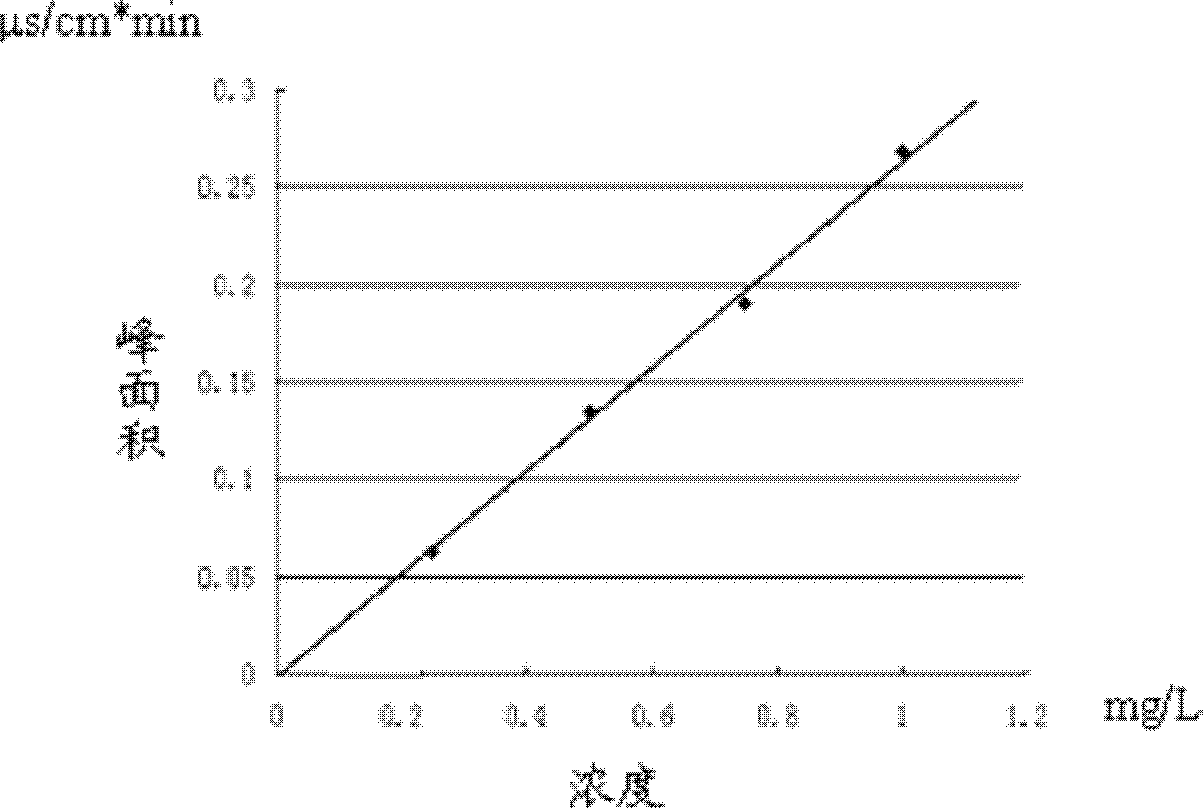

[0056] Test the sample to be tested: use 3-8mmol / L HNO3 The solution washes the chromatographic column in the ion chromatograph. Measuring Na in the sample to be tested by ion chromatograph + 、K + , Mg 2+ and Ca 2+ of the peak area. According to the corresponding standard curve established by each metal ion, the corresponding ...

Embodiment 2

[0061] Raw material, preparation test sample, and test test sample are all with embodiment 1, and wherein, eluent is 7mmol / LHNO 3 The mixture of dipicolinic acid and dipicolinic acid in a volume ratio of 10:1 is the eluent.

Embodiment 3

[0063] Raw materials, preparation of the sample to be tested, and testing of the sample to be tested are all the same as in Example 1, wherein the heating temperature of the water bath in the process of preparing the sample to be tested is 60 ° C, and the time is 4 hours; the number of times of adding high-purity water is 2 times, each 15ml . .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com