Measurement device of polymer viscoelastic model and measurement method of model element parameters

A technology for measuring devices and elastic modulus, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as not being able to become a concrete mechanical model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

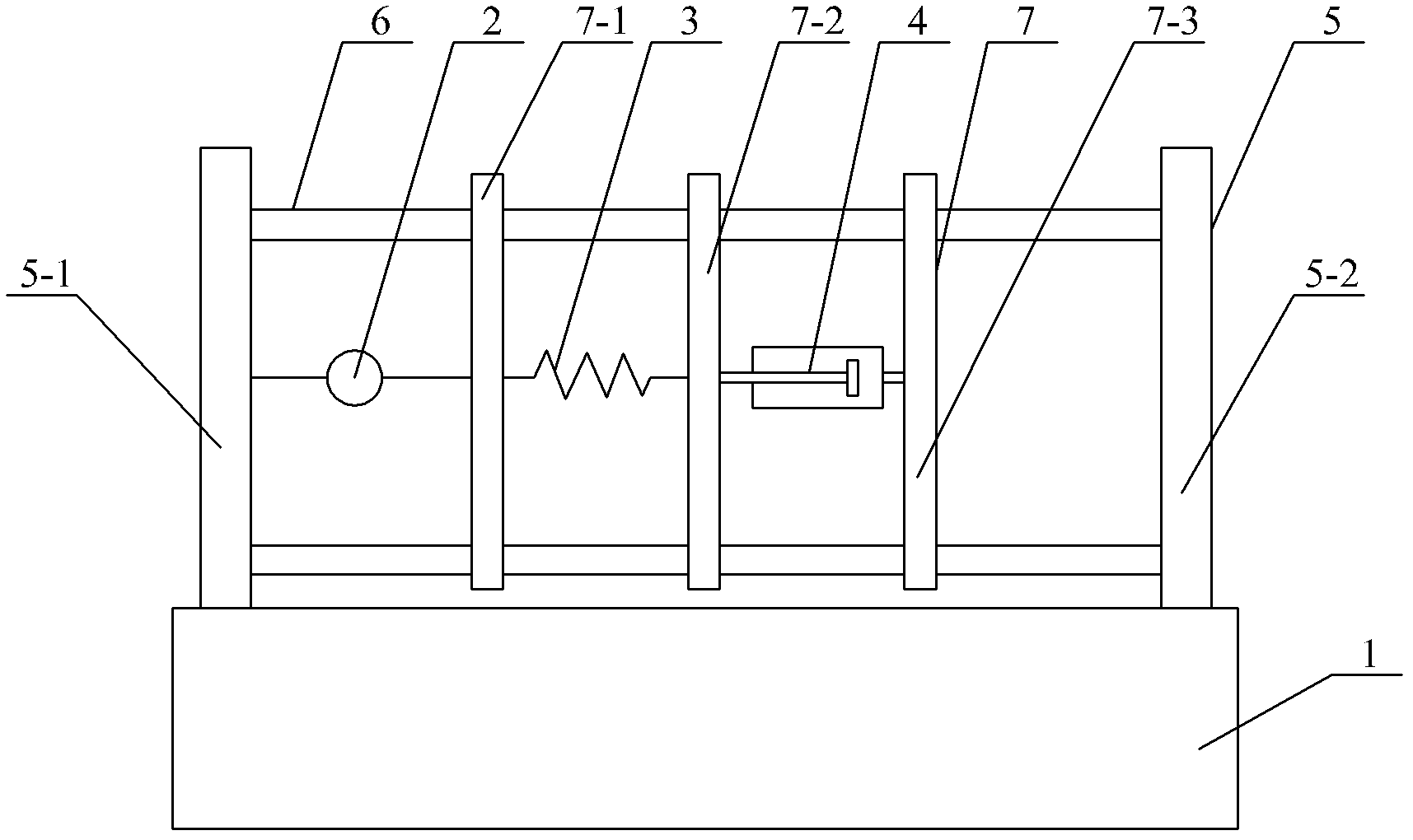

[0036] Specific implementation mode one: combine Figure 1a Explain that the measuring device of the polymer viscoelasticity model of the present embodiment is the measuring device of the Maxwell model, the measuring device base 1 of the Maxwell model, the dynamometer 2, the spring 3, the sticky pot 4, two fixed end plates 5, Four pull rods 6 and three movable plates 7; two fixed end plates 5 are respectively the first fixed end plate 5-1 and the second fixed end plate 5-2, and the three movable plates 7 are respectively the first movable plate 7- 1. The second movable board 7-2 and the third movable board 7-3;

[0037] Two fixed end plates 5 are fixed vertically and side by side on the base 1, four tie rods 6 are fixed horizontally and in a rectangular array between the two fixed end plates 5, and the frame is composed of four tie rods 6 and two fixed end plates 5 type structure, three movable plates 7 are arranged in parallel with two fixed end plates 5 and are located betwe...

specific Embodiment approach 2

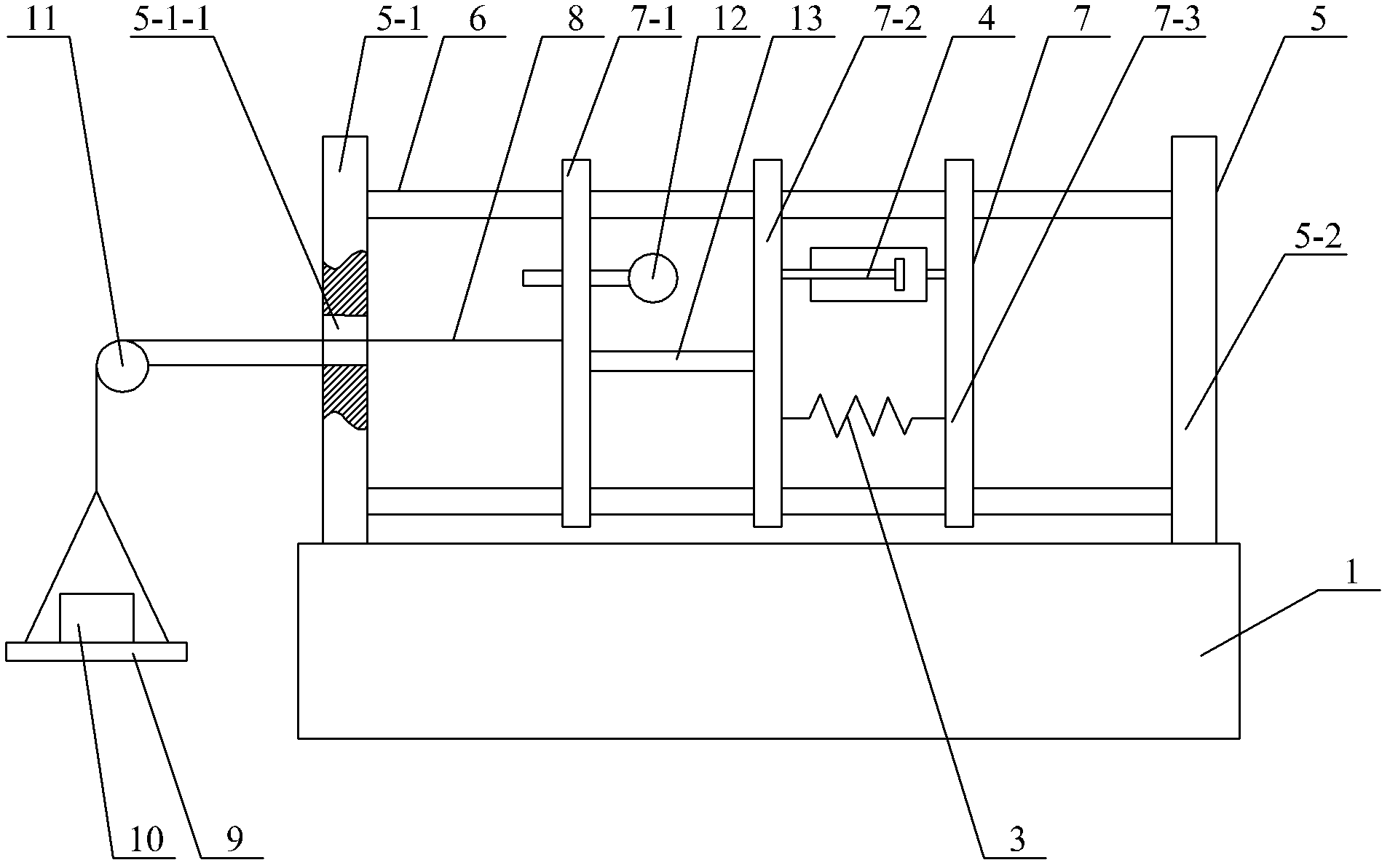

[0039] Specific implementation mode two: combination Figure 1b Description, the measuring device of the polymer viscoelasticity model of the present embodiment is the measuring device of the Kelvin model, and the measuring device of the Kelvin model comprises a base 1, a stay rope 8, a tray 9, a weight 10, and a fixed pulley 11 , strain gauge 12, spring 3, sticky pot 4, connecting rod 13, two fixed end plates 5, four pull rods 6 and three movable plates 7; the two fixed end plates 5 are respectively the first fixed end plates 5-1 And the second fixed end plate 5-2, the three movable plates 7 are respectively the first movable plate 7-1, the second movable plate 7-2 and the third movable plate 7-3;

[0040] Two fixed end plates 5 are fixed vertically and side by side on the base 1, four tie rods 6 are fixed horizontally and in a rectangular array between the two fixed end plates 5, and the frame is composed of four tie rods 6 and two fixed end plates 5 type structure, three m...

specific Embodiment approach 3

[0042] Specific implementation mode three: combination Figure 1c Explain that the measuring device of the polymer viscoelasticity model of the present embodiment is a measuring device of a three-element model, and the measuring device of the three-element model includes a base 1, a stay cord 8, a tray 9, a weight 10, a fixed pulley 11, a measuring Force gauge 2, strain gauge 12, sticky pot 4, two springs 3, two fixed end plates 5, four pull rods 6 and three movable plates 7; the two fixed end plates 5 are the first fixed end plates 5- 1 and the second fixed end plate 5-2, the three movable plates 7 are respectively the first movable plate 7-1, the second movable plate 7-2 and the third movable plate 7-3;

[0043] Two fixed end plates 5 are fixed vertically and side by side on the base 1, four tie rods 6 are fixed horizontally and in a rectangular array between the two fixed end plates 5, and the frame is composed of four tie rods 6 and two fixed end plates 5 type structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com