Dispersion measurement method of inorganic nano-particle composite polyimide film raw material

A technology of compounding polyimide and inorganic nanoparticles, which is applied in the direction of analyzing materials and instruments to achieve the effect of simple experimental equipment, saving time and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

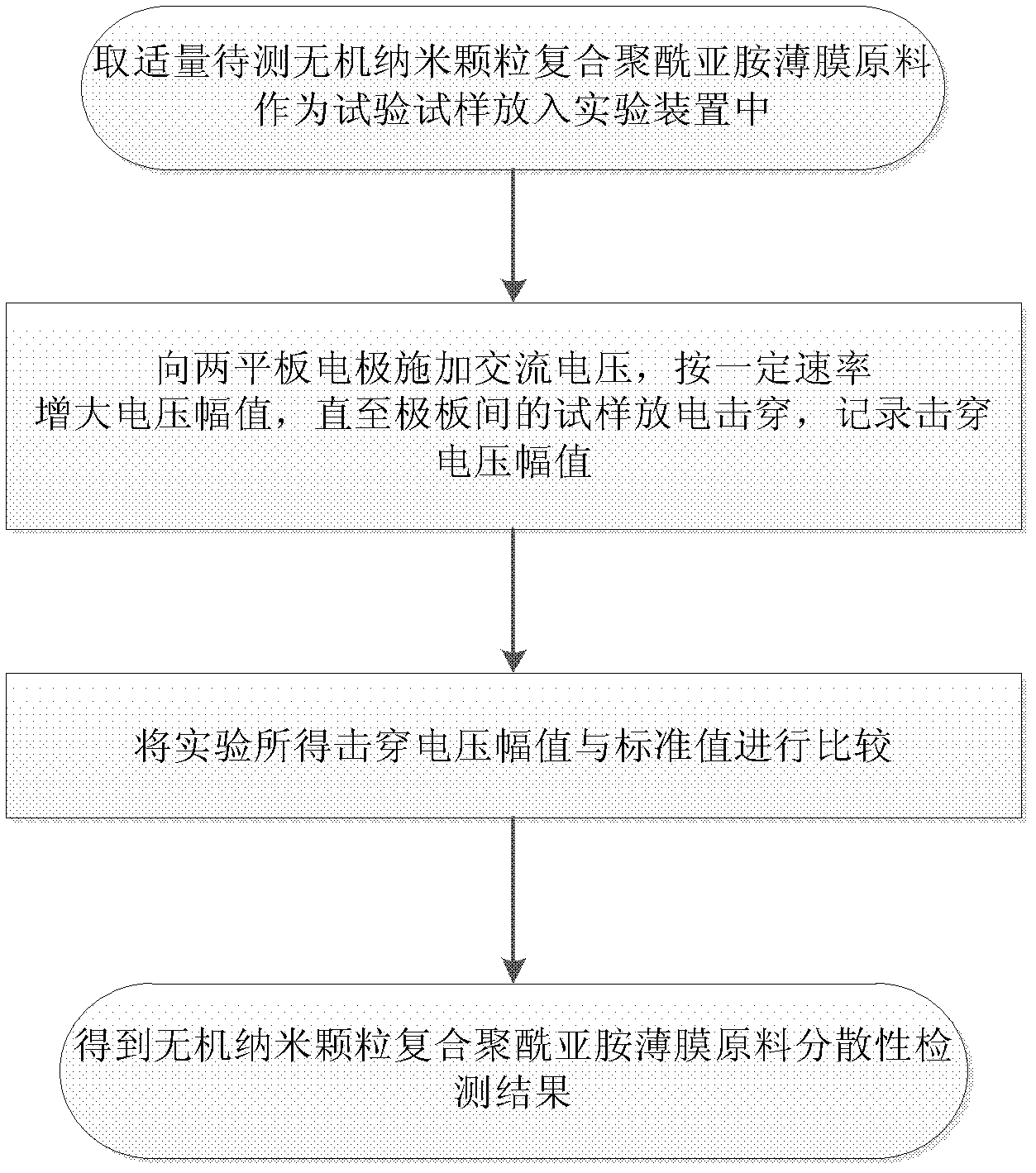

[0086] Example 1 (determination of standard voltage test sample)

[0087] (1) Nanocomposite polyimide films were prepared in the laboratory. In the preparation process, the nanoparticles are treated with a surface treatment agent to improve their dispersibility, and ultrasonic and mechanical blending methods are used in the dispersion process of the nanoparticles to fully disperse the nanoparticles. Divide the prepared inorganic nano / polyamic acid solution into two parts, one part is imidized to make a film finished product, and the finished product is imaged by scanning electron microscope to confirm its dispersibility. / polyamic acid solution as the standard voltage test sample.

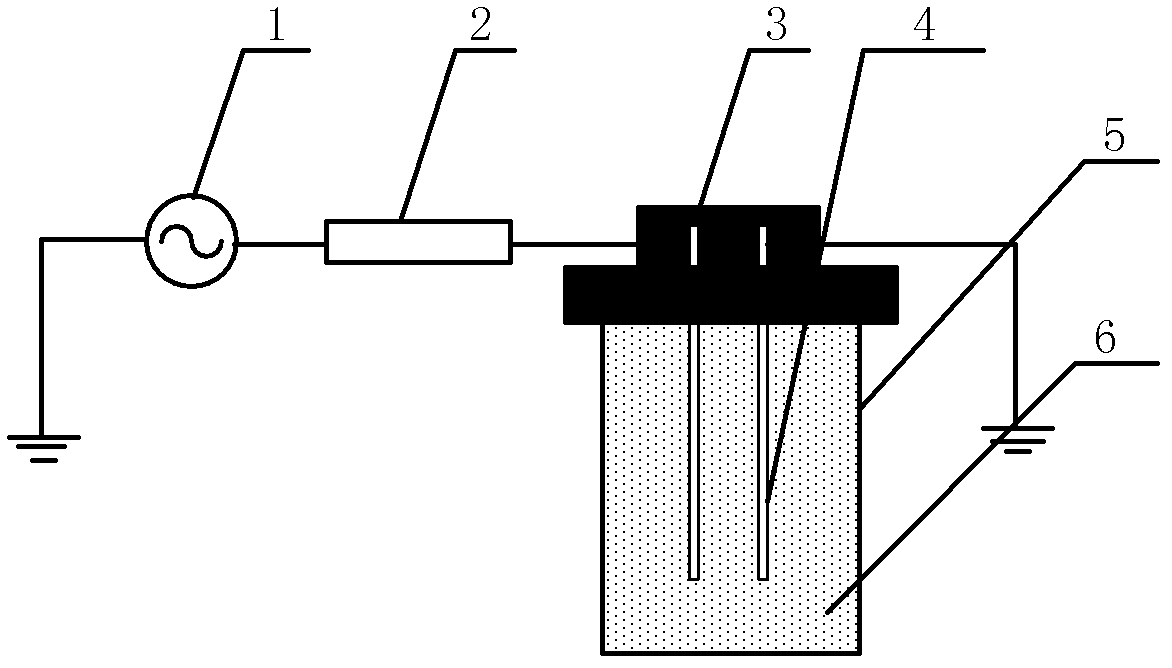

[0088] (2) Pour the raw material of the polyimide film to be tested into the detection device shown in the figure, fill the container, remove air bubbles in a vacuum environment, and then put a metal plate electrode into the sample;

[0089] (3) Connect the circuit according to the circuit shown ...

Embodiment 2

[0092] (1) The nanocomposite polyimide film was prepared in the laboratory. During the preparation process, the surface of the nanoparticles was not treated. The nanoparticles were dispersed by a pure mechanical dispersion method, and the raw material of the prepared nanocomposite polyimide film was taken as a test. sample. The method is the same as in Example 1, and the standard value is 4.14kV in Example 1.

[0093] (2) Pour the raw material of the polyimide film to be tested into the detection device shown in the figure, fill the container, remove air bubbles in a vacuum environment, and then put a metal plate electrode into the sample;

[0094] (3) Connect the circuit according to the circuit shown in the schematic diagram, apply 0-10kV AC voltage to the two pole plates, increase the voltage amplitude at a rate of 0.5kV / s, until the polyimide film material between the pole plates is discharged and broken down, record this When the breakdown voltage is 3.1kV;

[0095] (4)...

Embodiment 3

[0097] (1) Take the raw material of the nanocomposite polyimide film in the actual industrial production process as the detection cost. The standard value is still 4.14kV of Example 1.

[0098] (2) Pour the raw material of the polyimide film to be tested into the detection device shown in the figure, fill the container, remove air bubbles in a vacuum environment, and then put a metal plate electrode into the sample;

[0099] (3) Connect the circuit according to the circuit shown in the schematic diagram, apply 0-10kV AC voltage to the two pole plates, increase the voltage amplitude at a rate of 0.5kV / s, until the polyimide film material between the pole plates is discharged and broken down, record this When the breakdown voltage is 4.0kV;

[0100] (4) Compare the detected value of breakdown voltage in step (3) with the standard value of 4.14kV in step 1, and find that it is close to the standard value, the difference is within 5%, and the sample is deemed to have good dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com