Method and device for measuring thickness and refractive index of thin film

A technology of film thickness and refractive index, which is applied in measurement devices, optical devices, and phase influence characteristic measurement, etc., can solve the problems of difficulty in detecting surface microstructure parameters, spectroscopic methods requiring at least two measurements, and low interferometric measurement accuracy. , to achieve the effect of fast measurement speed, short measurement time and improved spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) The composition of the device

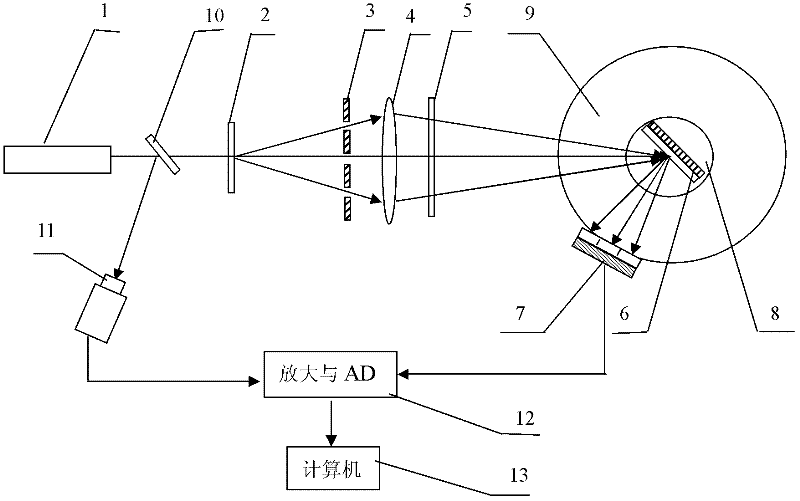

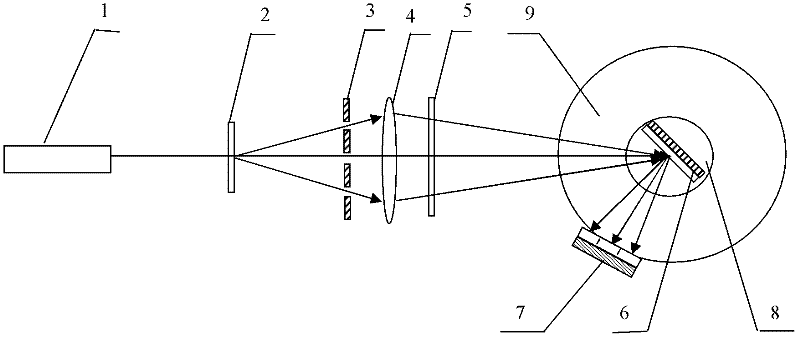

[0046] A device for measuring the thickness and refractive index of thin films such as figure 1 As shown: it includes a light source 1, a transmission grating 2, a diaphragm 3, a condenser lens 4, a polarizer 5, a photodetector 7, a sample rotating platform 8, a photodetector rotating platform 9, a beam splitter 10 and a Photodetector B11 of the light beam reflected by the beam splitter, signal sampling amplification and AD conversion circuit 12, and computer 13; along the direction of light advancement, light source 1, beam splitter 10, transmission grating 2, diaphragm 3, condenser lens 4 , the polarizer 5 and the sample rotating platform 8 are arranged in sequence, the axis of the sample rotating platform 8 coincides with the axis of the photodetector rotating platform 9, and the diameter of the photodetector rotating platform 9 is greater than the diameter of the sample rotating platform, so that it is located in the photodetector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com