Valve-equipped cylinder special for polisher

A polishing machine and cylinder technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of short service life, high working frequency, high power consumption, etc., achieve excellent dust prevention effect and short control air circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

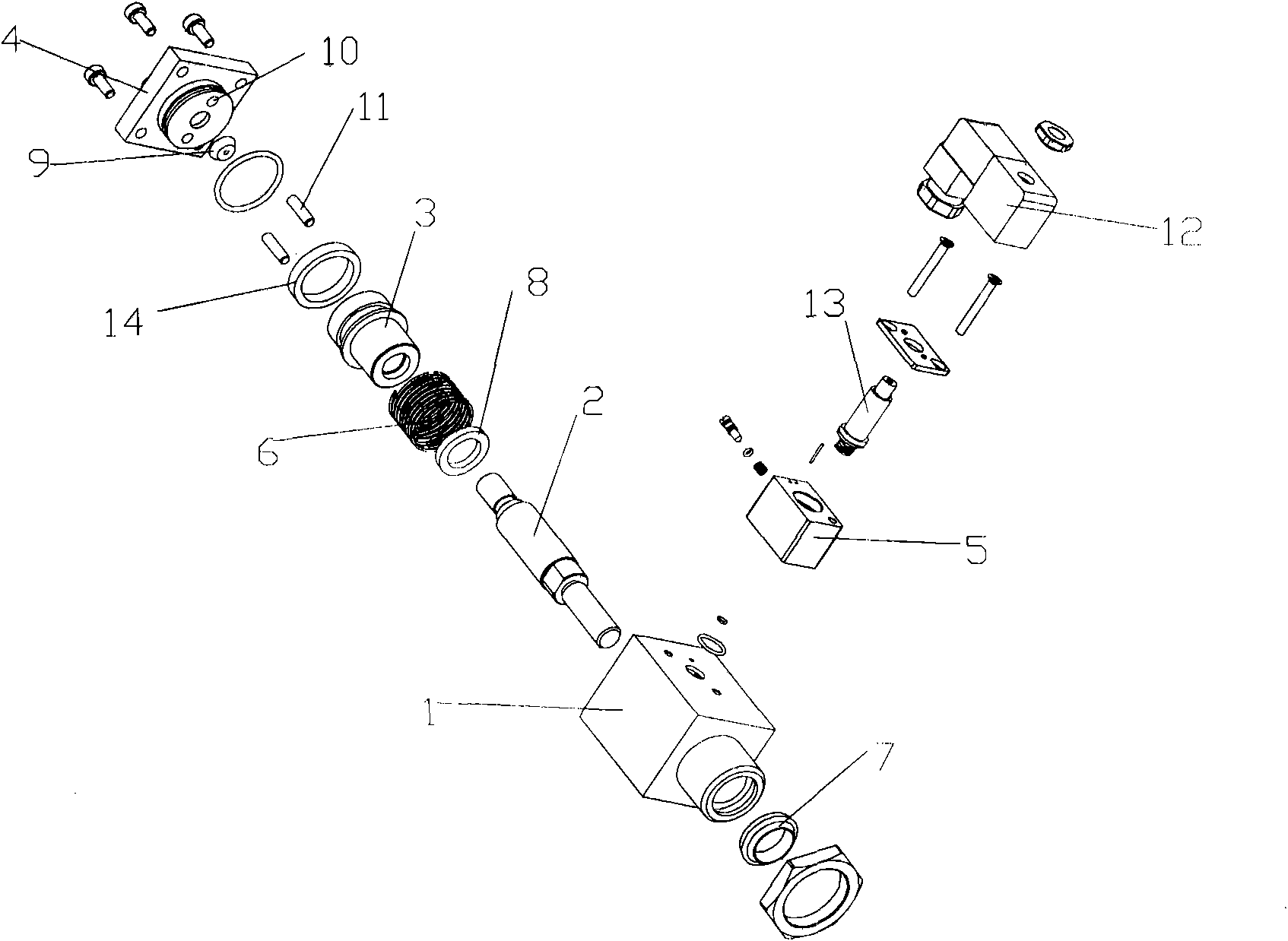

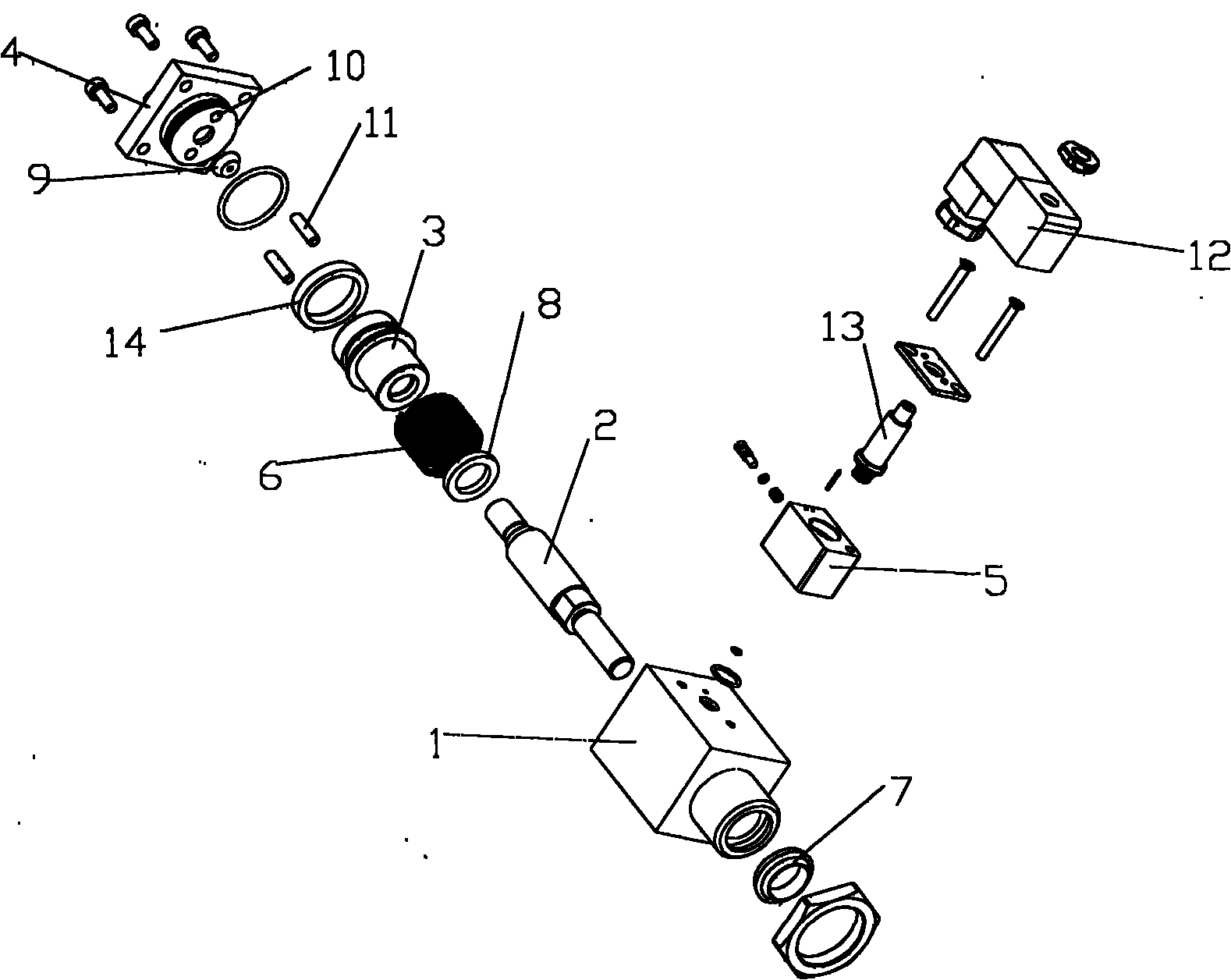

[0009] In order to facilitate the understanding of those skilled in the art, the sky spring of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0010] as attached figure 1 As shown, a valved cylinder specially used for a polishing machine includes a cylinder body 1, a piston rod 2 is arranged in the cylinder body, one end of which passes through the cylinder body 1, and the other end is sleeved with a piston 3, and a rear cover is arranged near the piston end 4. An intake valve 5 for controlling the air circuit is provided on the upper end of the cylinder body 1; a return spring 6 is provided on the piston rod. The end of the piston rod passing through the cylinder body 1 is provided with a polytetrafluoroethylene dustproof ring 7 . After the piston rod is socketed with the front buffer pad 8 earlier, it is threadedly socketed with the piston 3, and the back cover 4 is directly buckled with the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com