Method for preparing fluorescent anti-counterfeiting Lyocell fibers

A fluorescent and fiber technology, which is applied in the field of anti-counterfeiting chemical fiber preparation, can solve the problems of destroying fluorescent properties, and achieve the effect of expanding the application field, simple process, and good fluorescent anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

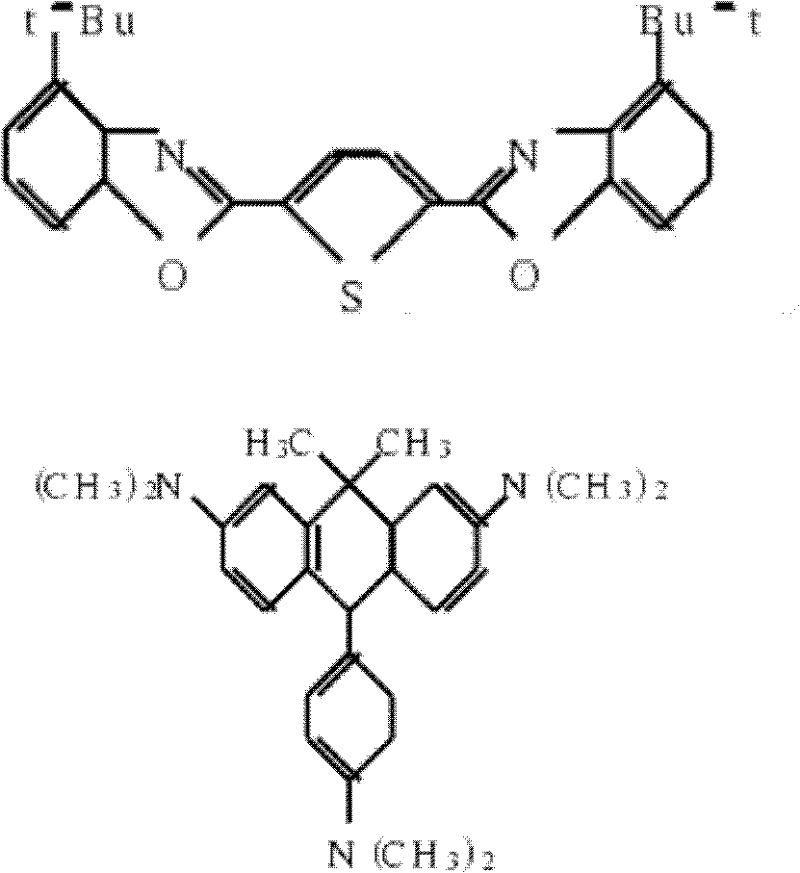

[0037] (1) Weigh 10g heterocyclic phenol fluorescent substance (structural formula: );

[0038](2) 4085g water content is the NMMO aqueous solution of 50% (mass percentage) to carry out vacuum distillation to obtain 2760g water content is the NMMO aqueous solution of 26% (mass percentage);

[0039] (3) Disperse the fluorescent substance obtained in step (1) into the NMMO aqueous solution obtained in step (2), ultrasonically treat it for 30 minutes, and then magnetically stir for 2 hours, so that the fluorescent substance is uniformly dispersed in the NMMO aqueous solution to form a suspension;

[0040] (4) Add 205g of cellulose cotton pulp and the suspension obtained in step (3) into the dissolving device. Stirring at 90°C and distilling under reduced pressure to remove water, to generate a ternary system of fluorescent substance / cellulose / NMMO aqueous solution with a water content of 13%, that is, fluorescent Lyocell spinning stock solution;

[0041] (5) Dry-wet spinning t...

Embodiment 2

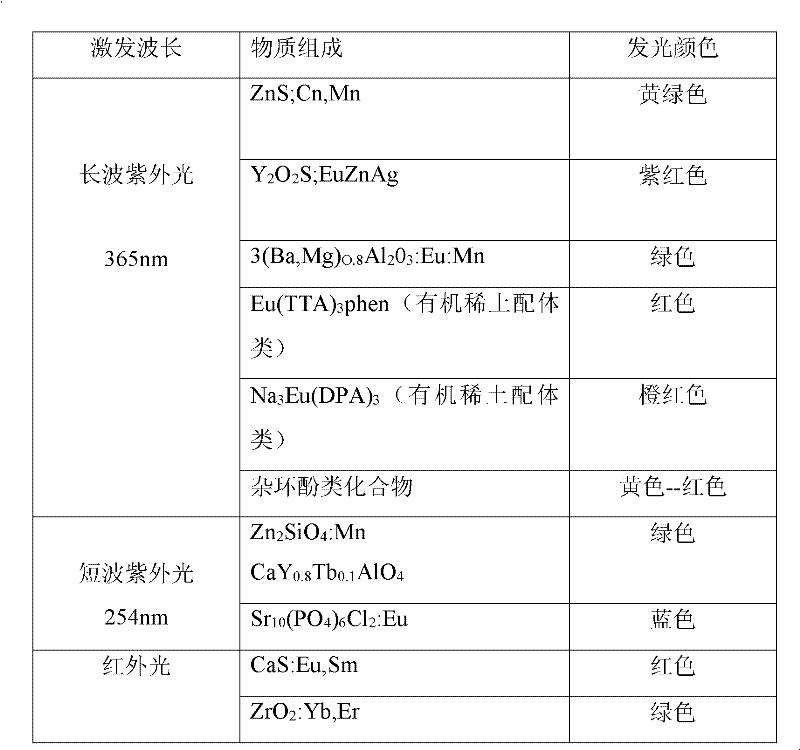

[0043] (1) Mix 10g inorganic fluorescent substance (main components: ZnS:Cn, Mn) and 25g glycerol (mass ratio 1:2.5), then add 0.1g titanate coupling agent and 0.6g glycerol The mixed solution (mass ratio 1:6), the coupling agent is evenly dispersed on the surface of the fluorescent powder by magnetic stirring, and the pretreated fluorescent substance is obtained after evaporating glycerol;

[0044] (2) 4085g water content is the NMMO aqueous solution of 50% (mass percentage) to carry out vacuum distillation to obtain 2760g water content is the NMMO aqueous solution of 26% (mass percentage);

[0045] (3) Disperse the fluorescent substance obtained in step (1) into the NMMO aqueous solution obtained in step (2), ultrasonically treat it for 30 minutes, and then magnetically stir for 2 hours, so that the fluorescent substance is uniformly dispersed in the NMMO aqueous solution to form a suspension;

[0046] (4) Add 205g of cellulose cotton pulp and the suspension obtained in step...

Embodiment 3

[0049] (1) 25g of long-wave anti-counterfeiting fluorescent substance (main component: Y 2 o 2 S; EuZnAg) and 25g short-wave fluorescent substance (main component: CaY 0.8 Tb 0.1 AlO 4 ). Stir and dry in a high-speed mixer preheated to 80-90°C, then evenly add 0.5g of titanate coupling agent (diluted with an appropriate amount of ethanol), and stir for 10 minutes to obtain a mixed fluorescent substance;

[0050] (2) 2960g water content is 50% (mass percentage) NMMO aqueous solution is carried out underpressure distillation to obtain 2000g water content is the NMMO aqueous solution of 26% (mass percentage);

[0051] (3) Dispersing 4 g of the mixed fluorescent substance obtained in step (1) into the NMMO aqueous solution obtained in step (2), ultrasonically treating for 1 hour, and then magnetically stirring for 4 hours, so that the fluorescent substance is uniformly dispersed in the NMMO aqueous solution to form a suspension;

[0052] (4) 160g of cellulose wood pulp step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com