Sand charging groove for manufacturing electroplated diamond fretsaw

An electroplating diamond and sand tank technology, applied in electrolytic coatings, coatings and other directions, can solve the problems of difficulty in sand fixing and the quality of wire saw products cannot be guaranteed, and achieve the effects of easy manufacturing, improved uniformity of micropowder distribution, and improved cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

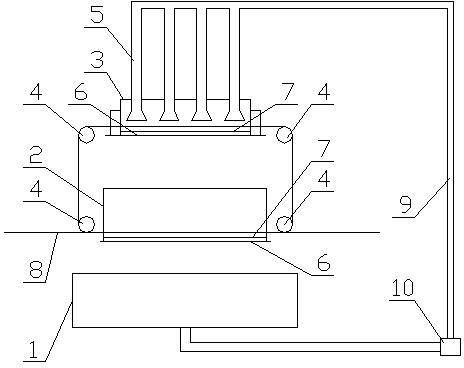

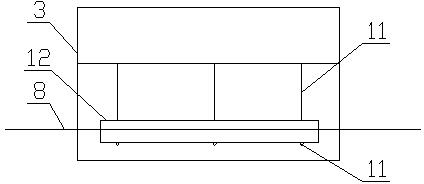

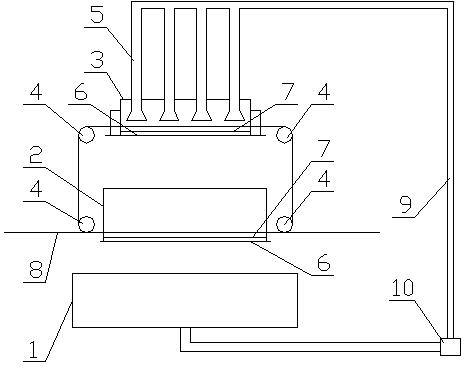

[0015] Such as figure 1 and figure 2 The shown upper sand tank for the manufacture of electroplated diamond wire saws includes a circulation tank 1 and a lower upper sand tank 2 and an upper upper sand tank 3 arranged at intervals above the circulation tank 1, and the lower upper sand tank 2 and the upper sand tank The bottom of the tank 3 is provided with a leaking plate 6 with a leaking hole, and a gauze 7 is provided above the leaking plate 6 at the bottom of the bottom upper sand tank 2 and the upper sand tank 3 . Above the sand tank 3 on the upper part, there is a liquid inlet hole 5 that communicates with the circulation tank 1 through a liquid pipe 9. Gauze is provided at the mouth of the liquid inlet hole. The metal wire substrate 8 below. The chemical pump 10 is connected on the liquid pipe 9, and the chemical pump 10 is used to pump the plating solution and the diamond micropowder in the circulation tank 1 into the upper upper sand tank 3 together, and can keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com