A water-bath thermal oxidation treatment method for the surface of medical titanium and titanium alloys

A treatment method, titanium alloy technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of low cost performance, uneven oxide film growth, large internal stress, etc., to improve surface hardness and Abrasion resistance, solution to uneven growth, and high film-base binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

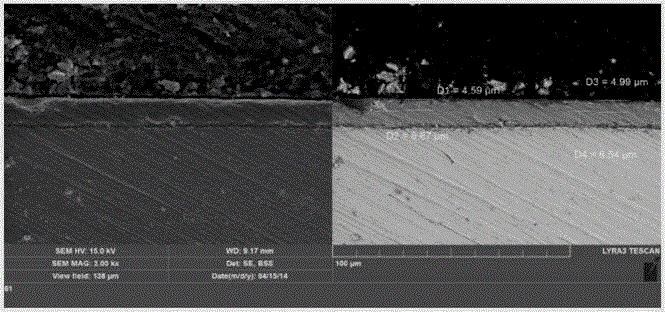

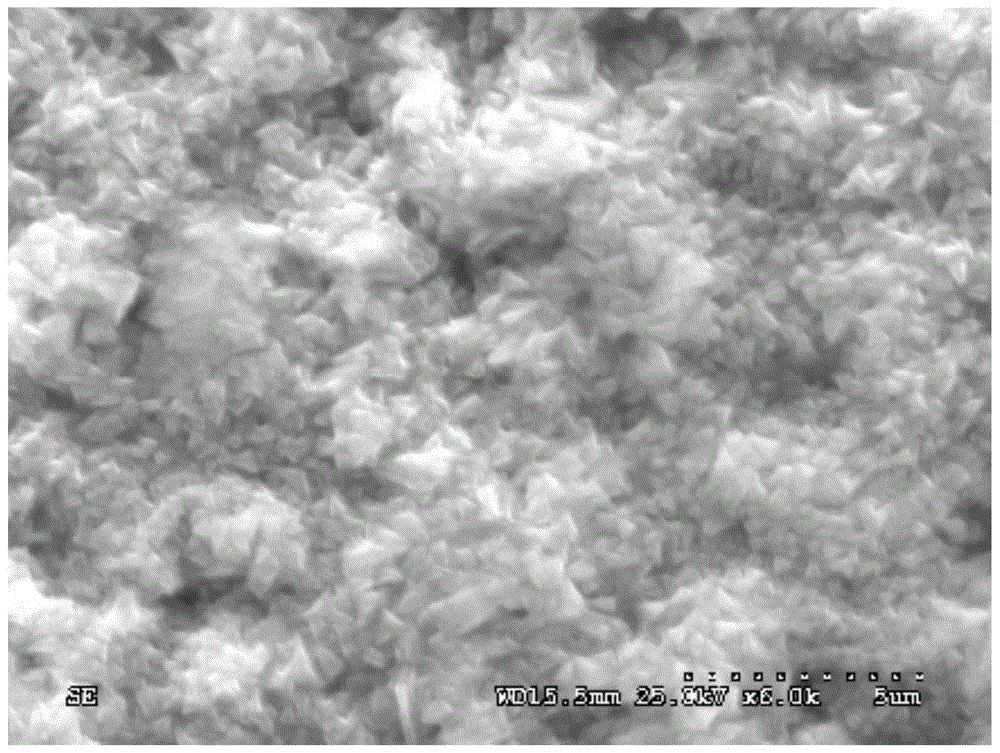

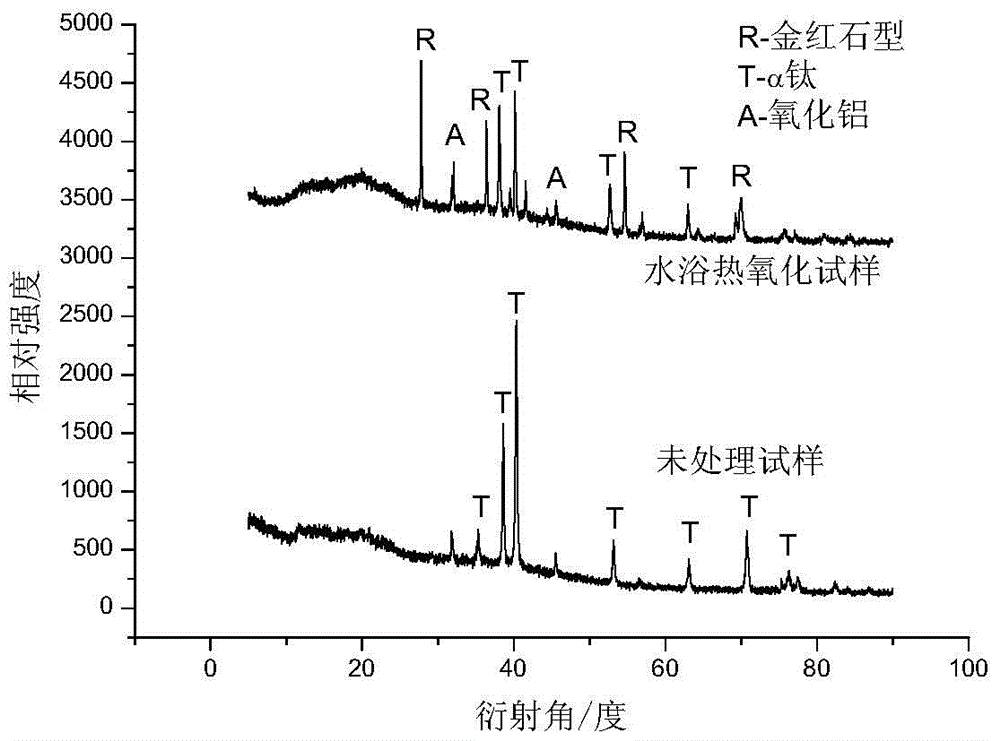

[0032] In this embodiment, a medical titanium disk is used as a sample, and the thickness of the prepared oxide film is about 5 μm, and the microhardness is about 600 HV. The specific steps are as follows: the sample is ground and polished to a surface roughness of 0.05-0.1μm, ultrasonically cleaned in absolute ethanol or acetone solution for 20 minutes, then ultrasonically cleaned in deionized water for 20 minutes, and finally placed in a vacuum drying oven Dry for 24 hours for later use. Put the processed sample into the thermal oxidation tube furnace, set the oxidation temperature to 600℃, the heating rate to 5℃ / min, and the oxidation holding time for 3 hours. After the temperature rises to 600℃, start to transfer to the tube furnace Into the boiling water vapor, the water vapor flows out from the other outlet of the tube furnace. After the holding time is up, the natural cooling method in the furnace is adopted, but the boiling water vapor is still introduced until the temp...

Embodiment 2

[0034] In this embodiment, a medical titanium disk is used as a sample, and the thickness of the prepared oxide film is about 8 μm, and the microhardness is about 700 HV. The specific steps are as follows: the sample is polished to a surface roughness of 0.02-0.2μm, ultrasonically cleaned in absolute ethanol or acetone solution for 30 minutes, then ultrasonically cleaned in deionized water for 30 minutes, and finally placed in a vacuum drying oven Dry for 24 hours for later use. Put the processed sample into the thermal oxidation tube furnace, set the oxidation temperature to 800℃, the heating rate to 5℃ / min, and the oxidation holding time for 8 hours. After the temperature rises to 800℃, start to transfer to the tube furnace Into the boiling water vapor, the water vapor flows from the other outlet of the tube furnace. After the holding time is up, the natural cooling method in the furnace is adopted, but the boiling water vapor is still introduced until the temperature in the ...

Embodiment 3

[0036] In this embodiment, a medical titanium alloy (Ti6Al4V) artificial cervical intervertebral disc upper endplate joint prosthesis is used as a sample, and the thickness of the prepared oxide film is about 10 μm, and the microhardness is about 800 HV. The specific steps are as follows: professionally polish the articular surface of the prosthesis sample to a surface roughness of 0.08~0.1μm, ultrasonically clean in absolute ethanol or acetone solution for 20 minutes, then ultrasonically clean in deionized water for 30 minutes, and finally place it Dry in a vacuum drying oven for 24 hours for later use. Put the processed prosthesis sample into a thermal oxidation tube furnace, set the oxidation temperature to 700°C, the heating rate to 5°C / min, and the oxidation holding time to 4 hours. After the temperature rises to 700°C, the tube will start to flow. Boiling water vapor is introduced into the furnace, and the water vapor flows out from the other outlet of the tube furnace. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com