Nanometer composite coal-economizing agent for power plant boiler

A nano-composite and coal-saving agent technology, applied in the field of coal-fired additives, can solve the problems of not obvious desulfurization effect, inability to support combustion by burning coal in boilers, inconvenience in production and life, etc., to promote ion exchange and oxidation-reduction reactions, The effect of sufficient combustion and accelerated decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

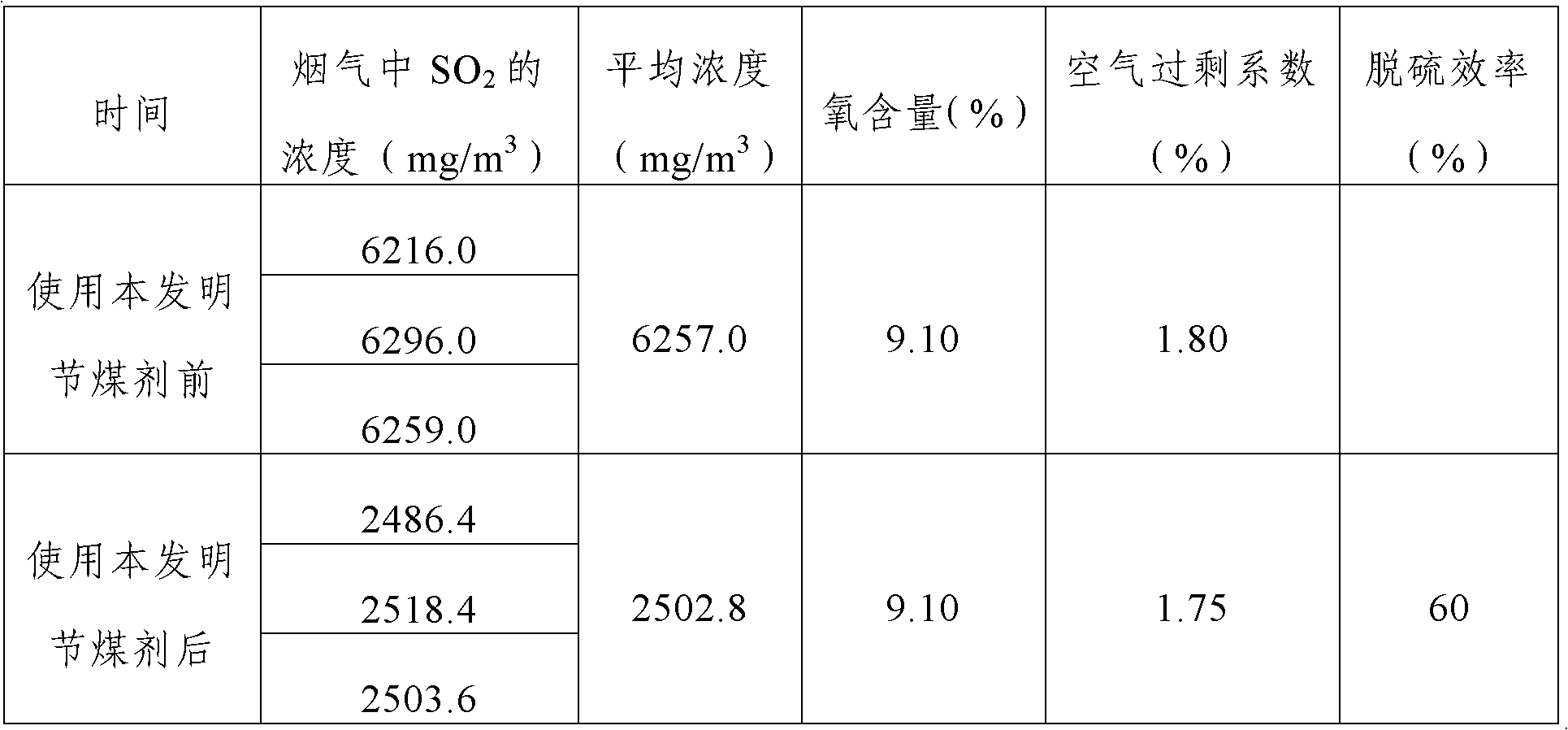

Examples

Embodiment 1

[0019] Each raw material is weighed according to the following weight percentages: calcium hydroxide 30%, nano-titanium crystal 3%, sodium nitrate 15%, ammonium nitrate 10%, iron oxide 10%, aluminum oxide 10%, activated carbon 15%, sodium carbonate 7%; The nano-titanium crystal refers to nano-scale rutile phase TiO 2 powder.

[0020] The preparation process of this example is as follows: Weigh the raw materials according to the above weight percentages and mix them, then crush the mixed raw materials to a powder with a particle size of 80-100 meshes, and finally put the powders in a mixer and stir them evenly. Packaged into a finished product.

Embodiment 2

[0022] Each raw material is weighed according to the following weight percentages: calcium hydroxide 50%, nano-titanium crystal 4%, sodium nitrate 15%, ammonium nitrate 5%, iron oxide 6%, aluminum oxide 5%, activated carbon 5%, sodium carbonate 10%; The nano-titanium crystal refers to nano-scale rutile phase TiO 2 powder.

[0023] The preparation process of this embodiment is the same as that of Example 1.

Embodiment 3

[0025] Each raw material is weighed according to the following weight percentages: calcium hydroxide 25%, nano-titanium crystal 5%, sodium nitrate 10%, ammonium nitrate 10%, iron oxide 10%, aluminum oxide 15%, activated carbon 15%, sodium carbonate 10%; The nano-titanium crystal refers to nano-scale rutile phase TiO 2 powder.

[0026] The preparation process of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com