Metal powder directional resin composition

A technology of resin composition and metal powder, applied in the direction of coating, etc., can solve the problems of poor solvent resistance and interlayer adhesion, poor weather resistance without nitrocellulose, halogen-containing vinyl acetate resin, etc., and achieve excellent gloss The effect of promoting the alignment of metal powder and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of Embodiment 1 Metal Powder Oriented Resin Composition

[0035] Take 580 grams of toluene and put it into a four-necked reaction flask and heat it to 85°C. Mix 50 grams of isobornyl methacrylate monomer, 250 grams of methyl methacrylate monomer, and 150 grams of butyl methacrylate monomer. Body, 50 grams of butyl acrylate monomer, 70 grams of polyester resin (ETERKYD 3330-X-70-2 (Changxing)) and 10 grams of benzoyl peroxide are pre-mixed and dropped into the reaction bottle for about 2 hours After dripping, keep warm and solidify for 3 hours, pack it, and measure it with a Grignard viscometer (BYK-Gardner viscosity tube) to obtain a resin with a viscosity of Z1-Z2 and a solid content of 50%.

Embodiment 2

[0036] Embodiment 2 Preparation of Metal Powder Oriented Resin Composition

[0037] Put 295 grams of toluene and 260 grams of butyl acetate into a four-necked reaction flask and heat to 115°C, and mix 75 grams of isobornyl methacrylate monomer, 300 grams of methyl methacrylate monomer, 75 After the butyl acrylate monomer of gram, the butyl methacrylate monomer of 50 grams, the polyester resin (ETERKYD 5052-R-60 (Changxing)) of 50 grams are premixed with 5 grams of tert-butyl peroxybenzoate, Drop into the reaction bottle, drop it in about 2 hours, keep warm and solidify for 3 hours, pack it, and measure it with a gremlin viscometer (BYK-Gardner viscosity tube) to obtain a resin with a viscosity of Y~Z and a solid content of 50%.

Embodiment 3

[0038] Embodiment 3 Preparation of Metal Powder Oriented Resin Composition

[0039] Put 250 grams of xylene and 250 grams of butyl acetate into a four-necked reaction flask and heat to 125°C, and mix 25 grams of isobornyl methacrylate monomer, 225 grams of methyl methacrylate monomer, 150 grams of styrene, 50 grams of isobutyl acrylate monomer, 50 grams of hydroxyethyl acrylate monomer and 5 grams of tert-butyl peroxybenzoate are pre-mixed and dropped into the reaction bottle for about 3 hours Finished, and heat preservation and solidification for 3 hours, then packaged, measured with a Grücke viscometer (BYK-Gardner viscosity tube) to obtain a resin with a viscosity of X to Y and a solid content of 50%.

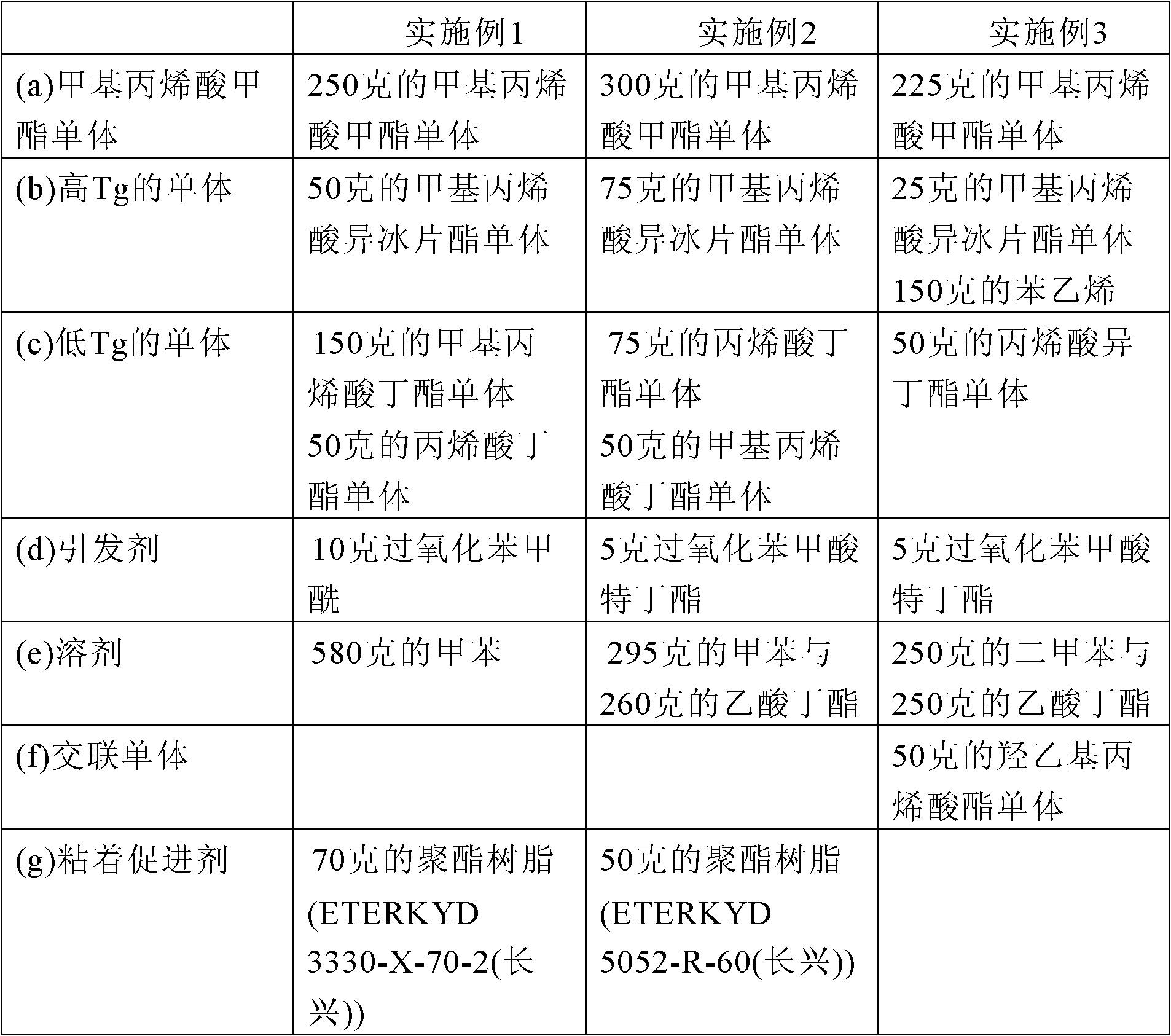

[0040] The components of the resin compositions of the aforementioned Examples 1 to 3 are organized in Table 1 below.

[0041] Table 1

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com