Flame retardant polyurethane composition, flame retardant polyurethane foam material and method for preparing same

A composition and polyurethane technology, applied in the field of flame retardant foam materials, can solve problems such as difficulty in exerting the effect of reactive flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

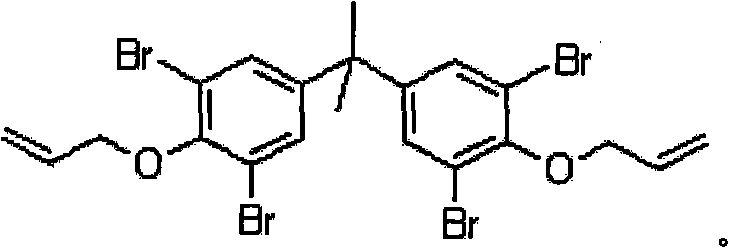

Image

Examples

Embodiment 1

[0068] The preparation of embodiment 1 flame-retardant polyurethane foam material

[0069] The formula of flame retardant polyurethane composition is as follows:

[0070] The first component: polyol H4110 is 100 parts, silicone oil AK-8805 is 2.0 parts, AE33 is 1.0 parts, stannous octoate is 0.7 parts, H 2 O is 1.0 parts, HCFC-141b is 25 parts, TBE is 80 parts, TCEP is 30 parts, β-HEMA is 10 parts, azobisisobutyronitrile is 0.5 parts,

[0071] The second component: 119 parts of PAPI.

[0072] The preparation method of flame-retardant polyurethane foam material is as follows:

[0073] The first component and the second component of the above-mentioned flame-retardant polyurethane composition are quickly mixed at room temperature of 25°C until they turn white, and then immediately injected into the pre-prepared mold cavity with a mold temperature of 30°C. Carry out foam molding, cool down to room temperature after keeping for 4 hours (hours), open the mold, and take out the f...

Embodiment 2

[0076] The preparation of embodiment 2 flame-retardant polyurethane foam material

[0077] The formula of flame retardant polyurethane composition is as follows:

[0078] The first component: polyol H4110 is 100 parts, silicone oil AK-8805 is 1.5 parts, AE33 is 1.0 parts, stannous octoate is 0.7 parts, H 2 O is 1.0 parts, HCFC-141b is 25 parts, TBE is 95 parts, TCEP is 50 parts, β-HEMA is 15 parts, azobisisobutyronitrile is 0.5 parts,

[0079] The second component: 125 parts of PAPI.

[0080] The preparation method of flame-retardant polyurethane foam material is as follows:

[0081] The first component and the second component of the above-mentioned flame-retardant polyurethane composition are quickly mixed at room temperature of 25°C until they turn white, and then immediately injected into the pre-prepared mold cavity with a mold temperature of 30°C. Carry out foam molding, cool down to room temperature after keeping for 4 hours, open the mold, and take out the foam from...

Embodiment 3

[0083] The preparation of embodiment 3 flame-retardant polyurethane foam material

[0084] The formula of flame retardant polyurethane composition is as follows:

[0085] The first component: 100 parts of polyol H4110, 1.5 parts of silicone oil AK-8805, 1.2 parts of AE33, 0.5 parts of stannous octoate, H 2 O is 1.0 parts, HCFC-141b is 25 parts, TBE is 85 parts, TCEP is 35 parts, β-HEMA is 10 parts, benzoyl peroxide is 0.5 parts,

[0086] The second component: 119 parts of PAPI.

[0087] The preparation method of flame-retardant polyurethane foam material is as follows:

[0088] The first component and the second component of the above-mentioned flame-retardant polyurethane composition are quickly mixed at room temperature of 25°C until they turn white, and then immediately injected into the pre-prepared mold cavity with a mold temperature of 30°C. Carry out foam molding, cool down to room temperature after keeping for 4 hours, open the mold, and take out the foam from the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com