Method for preparing tributyl citrate through diatomite immobilized titanium sulfate used as catalyst

A technology for the catalytic preparation of tributyl citrate, applied in the chemical industry, can solve the problems of complex post-treatment process, many side reactions, complex preparation process, etc., achieve easy recovery and reuse, improve the efficiency of esterification reaction, simplify the The effect of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Preparation of catalyst

[0023] Take 6g of diatomaceous earth and add it to 100mL of titanium sulfate solution with a mass fraction of 4%, and place it at 60°C and stir for 2h, evaporate the water in a vacuum, and dry the remaining solid at 100°C for 24h. Baking under the condition of ℃ for 6h.

[0024] 2) Esterification reaction

[0025] Add 270g of n-butanol, 200g of citric acid and 2g of catalyst in the reactor equipped with electromagnetic stirring, thermometer, reflux condenser, and water separator, heat and reflux at 120°C and stir, and the water produced by the reaction is separated from the water separator. The reaction stops when it enters the water separator until there is no water, and the crude product of tributyl citrate is obtained.

[0026] 3) Catalyst recovery and product purification

[0027] The crude product of tributyl citrate is filtered, and the catalyst filtered out is directly used in the next reaction; the filtrate is distilled under norm...

Embodiment 2-4

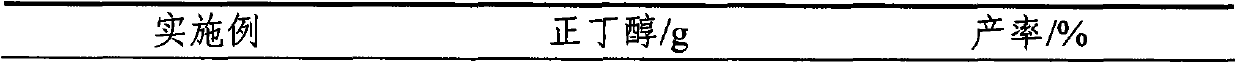

[0029] Only change n-butanol consumption, all the other are with embodiment 1. The results are shown in Table 1.

[0030] Table 1

[0031]

[0032]

Embodiment 5-7

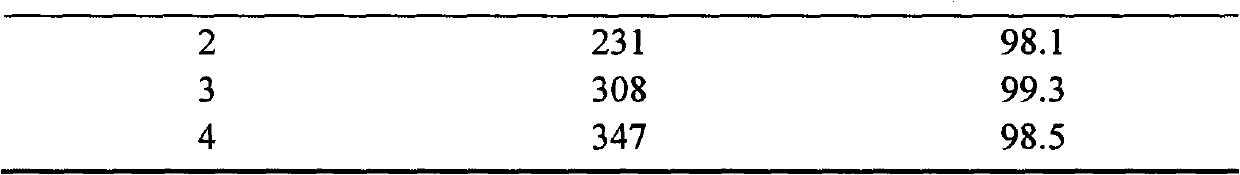

[0034] Only change the esterification reaction temperature, all the other are with embodiment 1. The results are shown in Table 2.

[0035] Table 2

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com