Extraction process for shikimic acid in fermentation liquor

An extraction process and fermentation liquid technology, applied in the field of bioengineering, can solve the problems of not being able to use directly, low content of shikimic acid, etc., and achieve the effects of reducing workload, high exchange capacity, and reducing wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

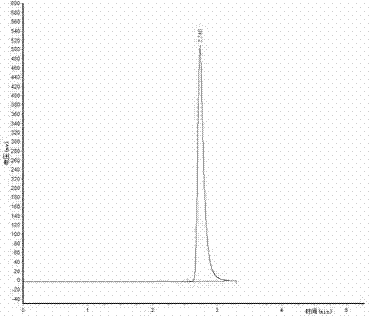

Examples

Embodiment 1

[0027] An extraction process for shikimic acid in a fermented liquid, specifically:

[0028] (1) 1000ml of fermentation broth (the specific gravity of fermentation broth is 0.98, the mass percentage of solid matter is 16%, of which shikimic acid is 30g) passed through Al 2 o 3 The ceramic membrane with a mass percentage of 99% is used for microfiltration, the pore size of the ceramic membrane is 0.1 μm, and the microfiltration flux is 10L / m 2 h.

[0029] (2) The filtrate obtained after microfiltration is ultrafiltered with a roll-type ultrafiltration membrane. The material of the ultrafiltration membrane is polyvinylidene fluoride. The molecular weight cut-off of the ultrafiltration membrane used is 5000 Daltons, and the ultrafiltration flux is 10L / m 2 h.

[0030] (3) The clear night obtained after ultrafiltration is exchanged and adsorbed with 717 anion exchange resin column, the column flow rate is 1BV / h, and the batch adsorption time is 8h; then it is eluted with 1mol / L ...

Embodiment 2

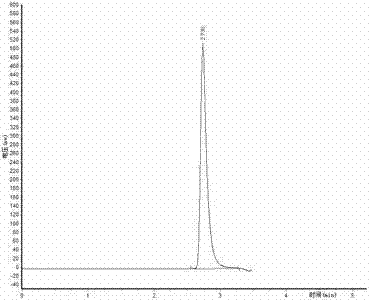

[0033] The difference from Example 1 is: when the eluate is concentrated under reduced pressure at 60° C. to a shikimic acid concentration of about 450 g / L in a concentration pot, powdered activated carbon is added for decolorization treatment, and the others are the same as in Example 1. Obtain 24.1g white powdery crystals at last, be exactly shikimic acid finished product (purity is 98.68%, yield 79.27%, see image 3 ).

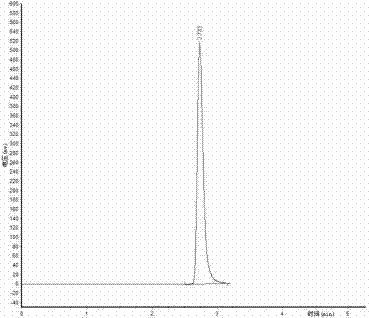

Embodiment 3

[0035] An extraction process for shikimic acid in a fermented liquid, specifically:

[0036] (1) 1000ml of fermentation broth (the specific gravity of fermentation broth is 0.98, the mass percentage of solid matter is 18%, of which shikimic acid is 33g) passed through Al 2 o 3 The ceramic membrane with a mass percentage of 99% is used for microfiltration, the pore size of the ceramic membrane is 0.5μm, and the microfiltration flux is 30L / m 2 h.

[0037] (2) The filtrate obtained after microfiltration is ultrafiltered with a roll-type ultrafiltration membrane. The material of the ultrafiltration membrane is polyvinylidene fluoride. The molecular weight cut-off of the ultrafiltration membrane used is 5000 Daltons, and the ultrafiltration flux is 30L / m2 h.

[0038] (3) The clear night obtained after ultrafiltration is exchanged and adsorbed with 717 anion exchange resin column, the column flow rate is 0.5BV / h, and the batch adsorption time is 10h; then it is eluted with 1.5mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com