Phosphorus plaster tablet processing method

A processing method and technology of gypsum board, which is applied in the field of household board production, achieves the effects of less land occupation, less investment and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

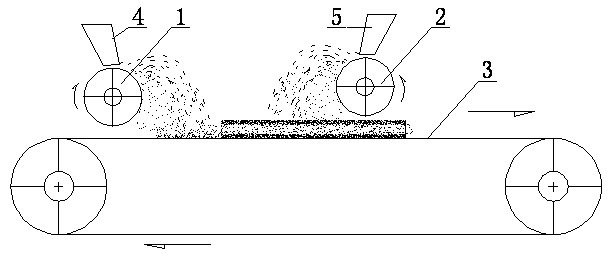

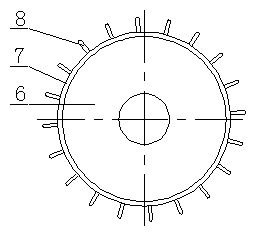

[0018] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

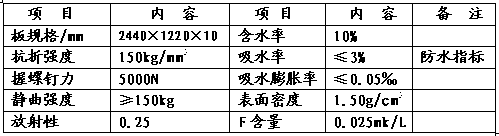

[0019] A method for processing a phosphogypsum board, comprising the following steps, a. mixing 75-85 parts by mass of hemihydrate gypsum particles and 15-25 parts of dihydrate gypsum particles and stirring evenly, and the hemihydrate gypsum particles and dihydrate gypsum particles are Particles with a size of 80-600 mesh sieve; b, adding 3-8 parts by mass of kapok fiber for stirring, adding 15-35 parts by mass of clear water for stirring to become uniformly mixed material particles, the clear water adopts Added by spraying, the kapok fiber refers to a mixture of wood fiber and cotton fiber, wherein the wood fiber specification: 1.5-3.5mm long, 0.01-0.5mm in diameter; cotton fiber specification: 0.01-15mm long, 0.01-0.5mm in diameter , the ratio is 50% each; c, spread the material, use a conveyor belt and two throwing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com