Sheet die-cutting machine

A die-cutting machine and sheet material technology, applied in metal processing and other directions, can solve problems such as inaccurate die-cutting alignment, low feeding accuracy, manual height adjustment, etc., to improve die-cutting quality, improve feeding accuracy, and accurately adjust depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

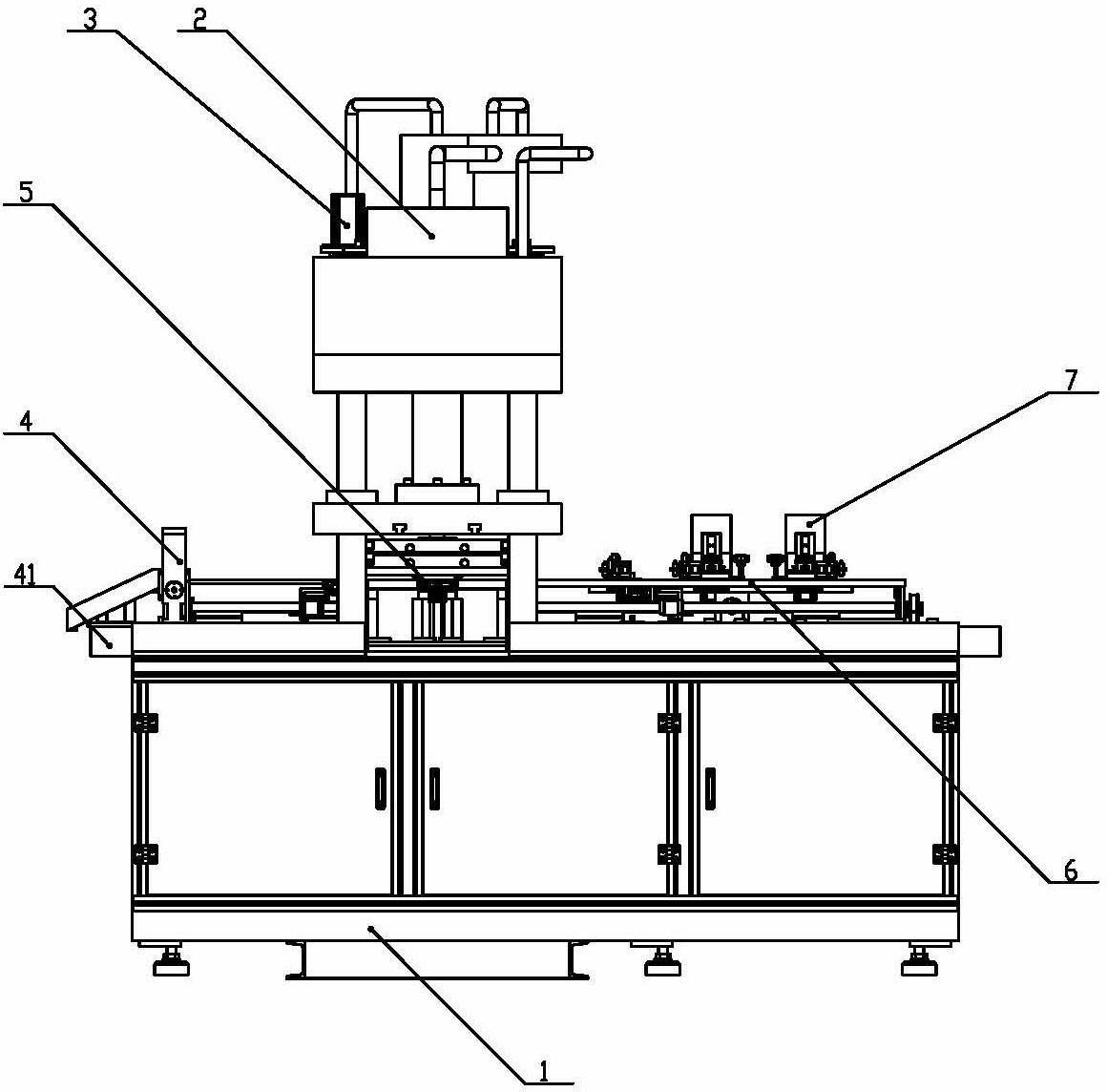

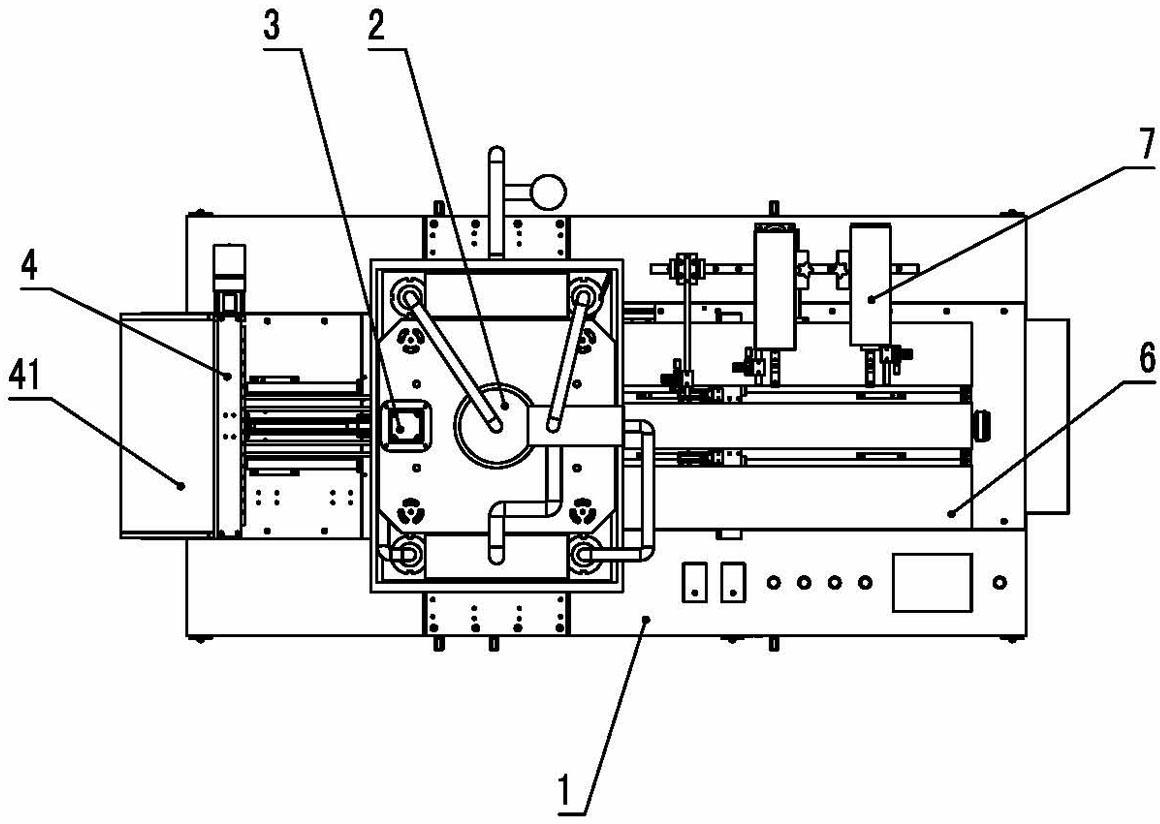

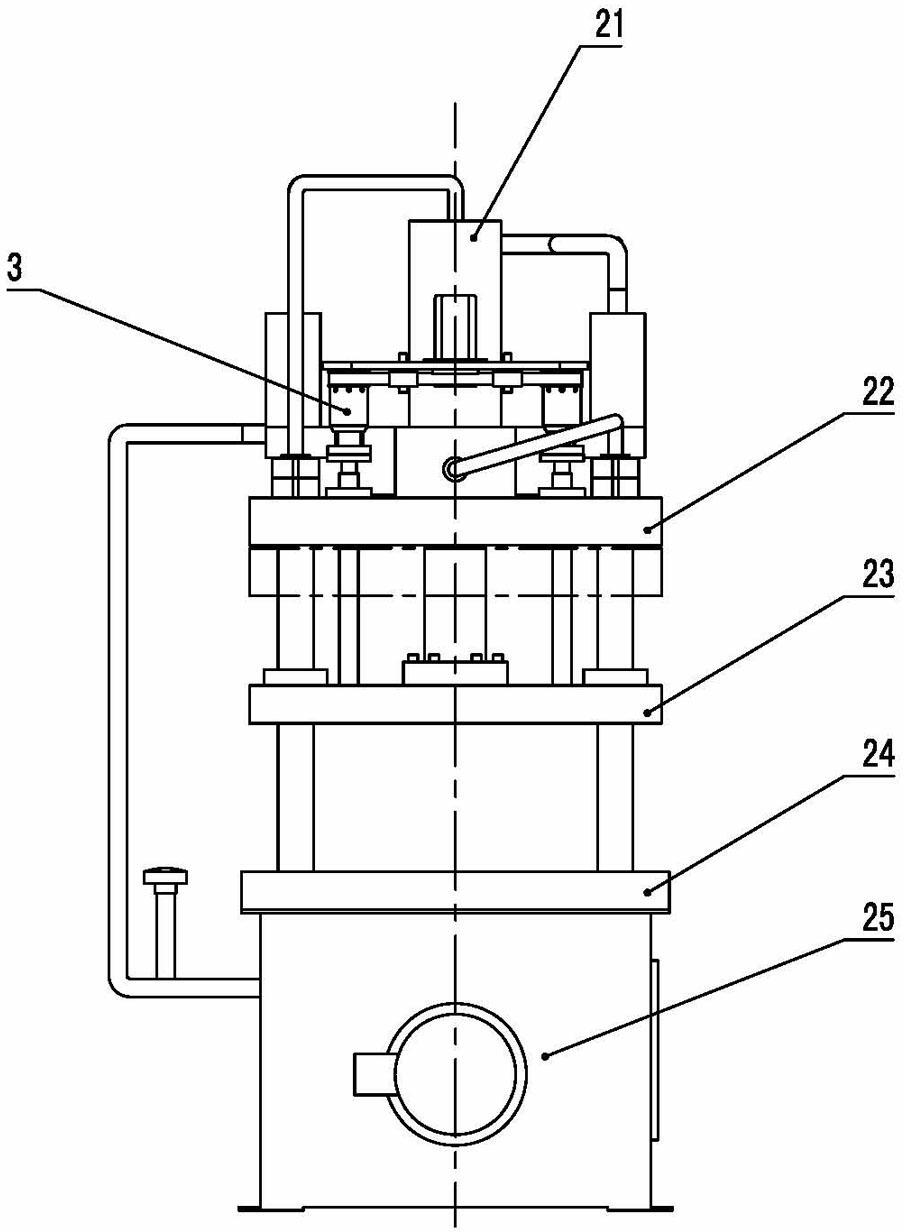

[0029] Figure 1 to Figure 10 The reference numerals in the figure are: machine base 1; hydraulic die-cutting mechanism 2; hydraulic cylinder 21; hydraulic cylinder mounting plate 22; movable platen 23; fixed platen 24; 31; motor mounting plate 311; belt transmission mechanism 32; intermediate runner 321; driving wheel 322; guide limit sleeve 33; limit nut 34; Z-axis screw mandrel 35; Cutter plate 5; servo slide feeding mechanism 6; feeding slide 61; first X-axis screw pair 62; sheet automatic deviation correction mechanism 7; second X-axis screw pair 71; Y-axis screw pair 72; Z-axis deviation correction execution Section 73.

[0030] Such as Figure 1 to Figure 10As shown, a sheet die-cutting machine includes a machine base 1 with a rigid frame, and the machine base 1 is provided with a servo slide feeding mechanism 6 for feeding materials,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com