Device and method for ultrafast picosecond pulse laser machining of super-hydrophobicity micro-structure surface

A super-hydrophobic, ultra-fast picosecond technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low output and high investment, and achieve the effect of low cost, simple process and green production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

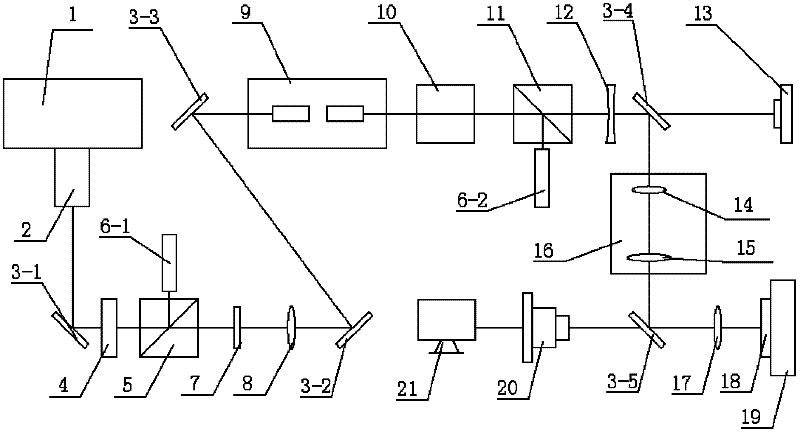

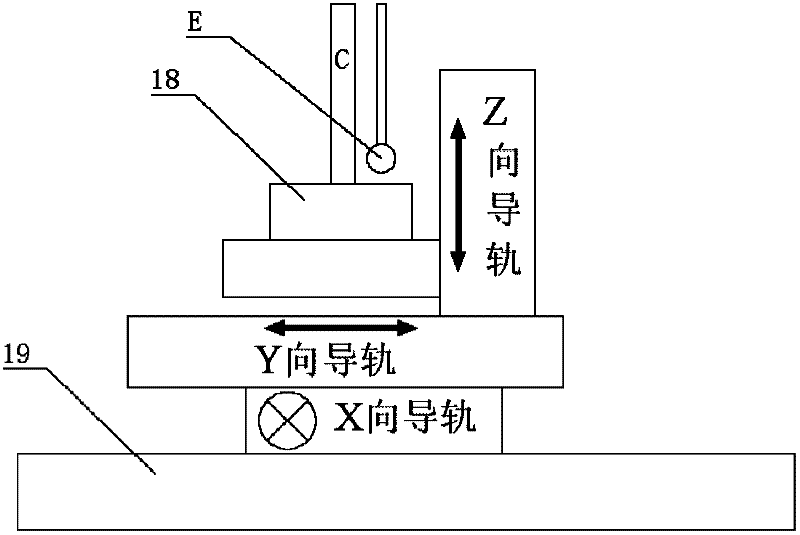

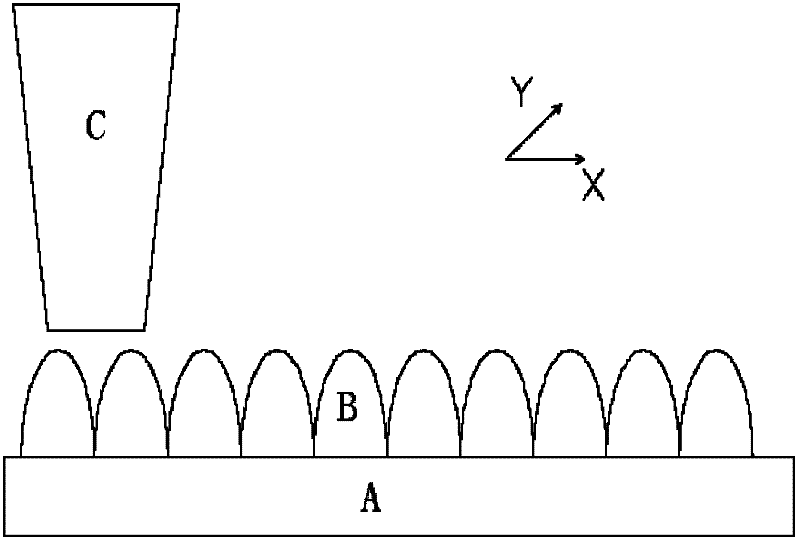

[0033] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment mode, the ultrafast picosecond pulse laser processing device of superhydrophobic microstructure surface described in this embodiment mode, it comprises ultrafast picosecond pulse laser source 1, optical frequency isolator 2, first mirror 3-1 , second mirror 3-2, third mirror 3-3, fourth mirror 3-4, fifth mirror 3-5, rotating liquid crystal polarizer 4, polarizing beam splitter 5, first beam collection Device 6-1, second beam collector 6-2, half-wave plate 7, first focusing lens 8, frequency doubling generator LBO crystal 10, dichroic mirror 11, light control device 12, beam profiler 13, Beam amplification component Kepler beam expander 16, focusing processing lens 17, processing platform 19, microscopic imaging CCD assembly 20 and control system 21,

[0034] The laser beam emitted by the ultrafast picosecond pulse laser source 1 is amplified by the built-in rege...

specific Embodiment approach 2

[0039] Specific implementation mode two: the following combination figure 1 Describe this embodiment, this embodiment is a further description of Embodiment 1, the beam amplification component Kepler beam expander 16 is composed of a second focusing lens 14 and a third focusing lens 15, through the fourth mirror 3- 4. The reflected light beam is expanded by the second focusing lens 14 and the third focusing lens 15 and then enters the fifth reflecting mirror 3-5.

[0040] The beam enlargement component The main purpose of the beam expander of the Kepler beam expander 16 is to increase the diameter of the beam, so that subsequent optical elements can be used to improve the quality of the beam itself. In the present invention, the beam expanded by the beam enlarger Kepler beam expander 16 should be compatible with the aperture of the focusing processing lens 17 .

specific Embodiment approach 3

[0041] Specific embodiment three: this embodiment is a further description of embodiment two, the focal length of the second focusing lens 14 is 40 mm, the focal length of the third focusing lens 15 is 100 mm, the second focusing lens 14 and the third focusing lens 15 The center distance is 140mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com