Method of electrochemical machining

An electrochemical machining and electrode technology, applied in the field of electrochemical shape correction machining, can solve the problems of increasing process power consumption, decreasing the conductivity of the electrolyte, reducing the profiling precision and reducing the concentration of hexavalent chromium ions in the waste electrolyte.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

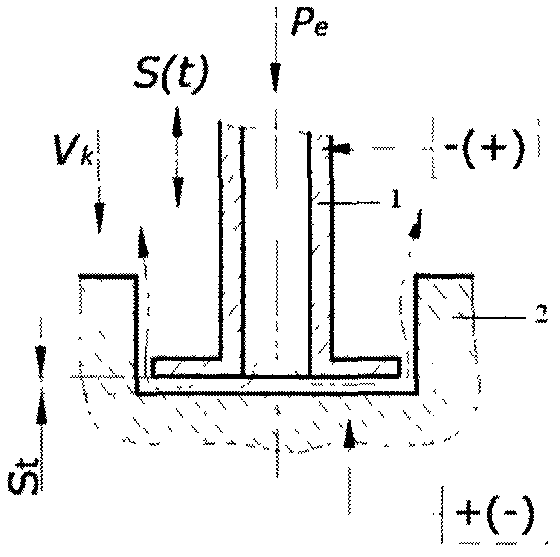

[0045] figure 1 A process flow diagram for pulsed bipolar electrochemical machining (ECM) by an oscillating EDM electrode in the ET series of machines in its most general form is illustrated. as figure 1 As shown, the machining electrode 1 oscillates periodically S(t) relative to the machining surface of the blank electrode 2 in the uniaxial feed direction Vk.

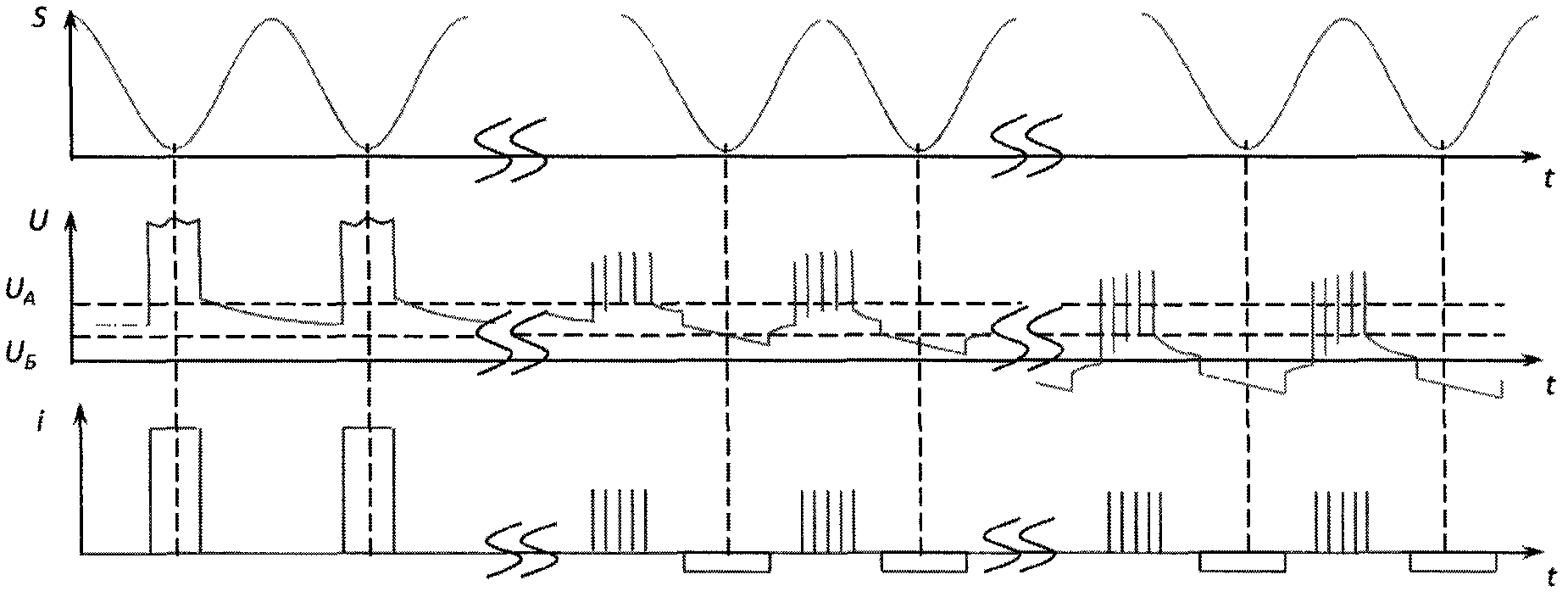

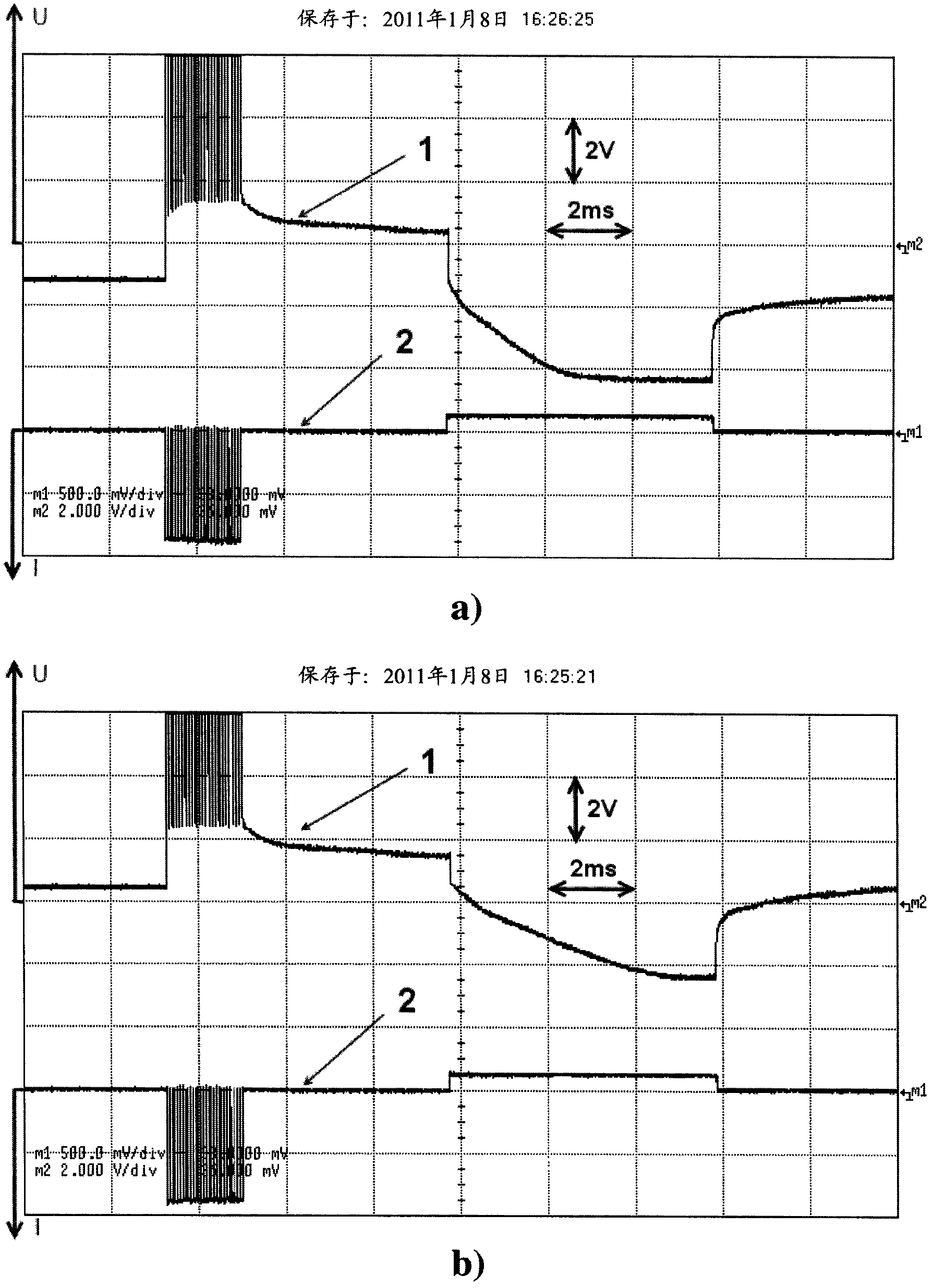

[0046] First, the supply has a high density (at 50A / cm 2 -1000A / cm 2 operating current pulses or groups of current pulses of positive polarity, then, when the predetermined depth of machining has been accomplished in the final step of the process, the current pulses of positive polarity and machine feed are stopped, and the total after the supply of the test low voltage pulse group is determined. The remnant polarization voltage UA( figure 2 ) and turn on the reverse polarity low-voltage current pulse, the supply moment of the reverse polarity pulse is also synchronized with the phase of the electrode being the ma...

Embodiment

[0063] Specific embodiments of electrochemical machining according to the inventive method of the present invention.

[0064] ECM of the inventive method by bipolar current pulses was carried out in an electrochemical profiling punching machine type ET500 manufactured by Ufa, "ECM" Ltd, Russia, using 40X13 steel as sample material and machining electrodes. at a depth of 5mm and 200mm 2 The area is processed in 9.5% sodium nitrate aqueous solution.

[0065] Before the processing step, the oscillating processing electrode 1 ( figure 1 ) and the processing blank 2 are close to each other to contact each other, and there is no process voltage on the processing electrode 1 and the processing blank 2 and they are moved to a predetermined value St=20 μm apart from the minimum inter-electrode gap ( figure 1 ).

[0066] Next, in the first processing step, the following processing modes by current pulses of positive polarity are set:

[0067] - the frequency of rectangular current p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com