Strongly alkaline anion exchange fibers as well as preparation method and applications thereof

A technology of exchange fiber and strong alkali, which is applied in the field of strong alkali anion exchange fiber and preparation, can solve the problems of affecting the adsorption performance of ion exchange fiber, poor mechanical strength and stability, complicated and complicated process, etc., and it is easy to achieve industrial promotion and implementation , wide applicability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of PP-g-AAm by pre-irradiation method

[0026] use 60 Coγ-ray pre-irradiation method, polypropylene (PP) fibers are placed in a sample bag, pre-irradiated with a dose rate of 2kGy / h for 40kGy, taken out and put into a desiccator, and stored in a freezer in a refrigerator for use. Quantitatively add 20ml of solution into a 50mL test tube, in which the concentration of ferrous ammonium sulfate (Mohr's salt) is 0.25%, the concentration of AAm is 20%, 1.6g of pre-irradiated PP fibers, and nitrogen gas is passed for 10 minutes. Put it in a constant temperature bath at 70°C for 4 hours, take out the grafted fiber and soak it in dilute hydrochloric acid solution for 24 hours, put it into a Soxhlet extractor and extract it with water for 6 hours to remove AAm monomer and its homopolymer. Vacuum dry at 60°C and -0.09MPa for 24h. After weighing, the grafting rate was calculated according to formula 1.

[0027] G = ...

Embodiment 2

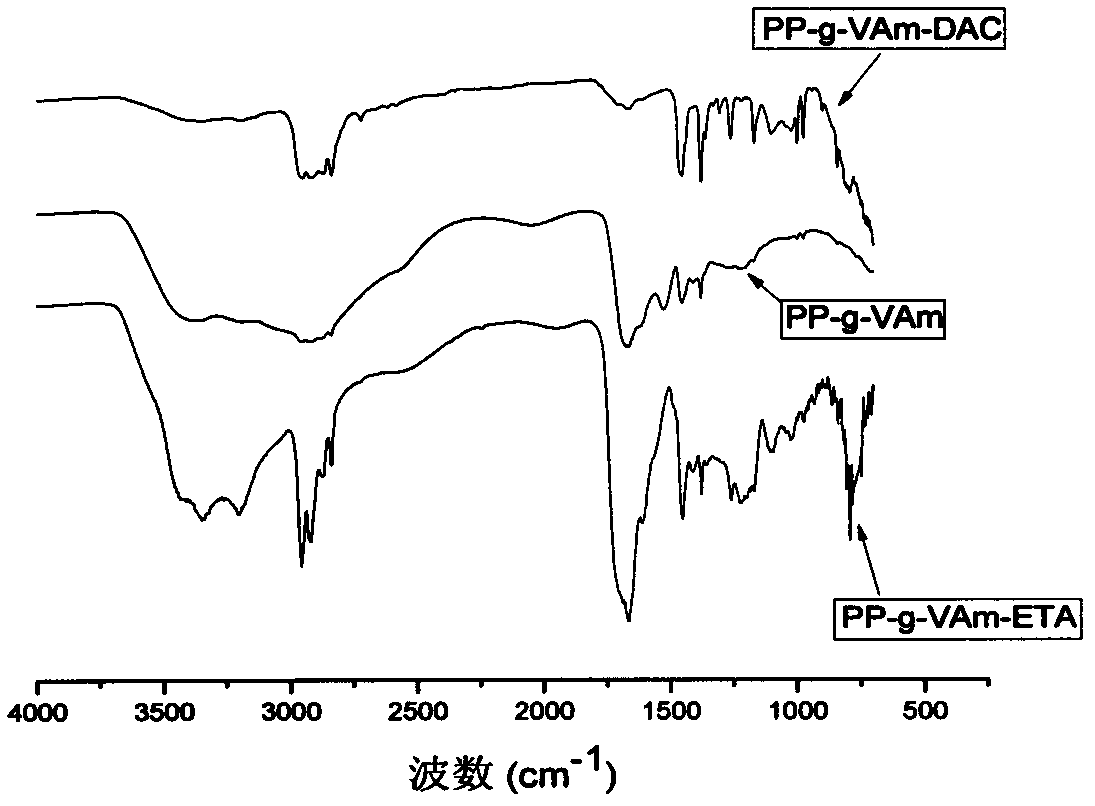

[0030] Example 2: Preparation of PP-g-VAm fibers by Hofmann degradation

[0031] Put 5g of PP-g-AAm grafted fibers in a 250ml Erlenmeyer flask, add 150ml of deionized water, and fully swell at 25°C for 24h. The reaction is carried out at -15 ° C ~ 0 ° C, according to the content of amide groups (P-CONH 2 ), sodium hypochlorite (C1O - ) and sodium hydroxide (OH - ) with a mass ratio of 1:1:25 was added to NaOH solution and NaClO solution, and reacted for 10 h. Then transfer the fiber to a 200ml ion exchange column (with a jacket, and pass through -1~1°C ice brine), wash the fiber with 500ml of methanol at -5~0°C until neutral, add 500ml of 12mol / L hydrochloric acid, release CO 2 gas. Wash with 1000ml of deionized water until neutral, and vacuum-dry at 60°C and -0.09MPa for 24h to obtain the degradation product PP-g-VAm fiber. The amino exchange capacity of fibers was determined by the following method:

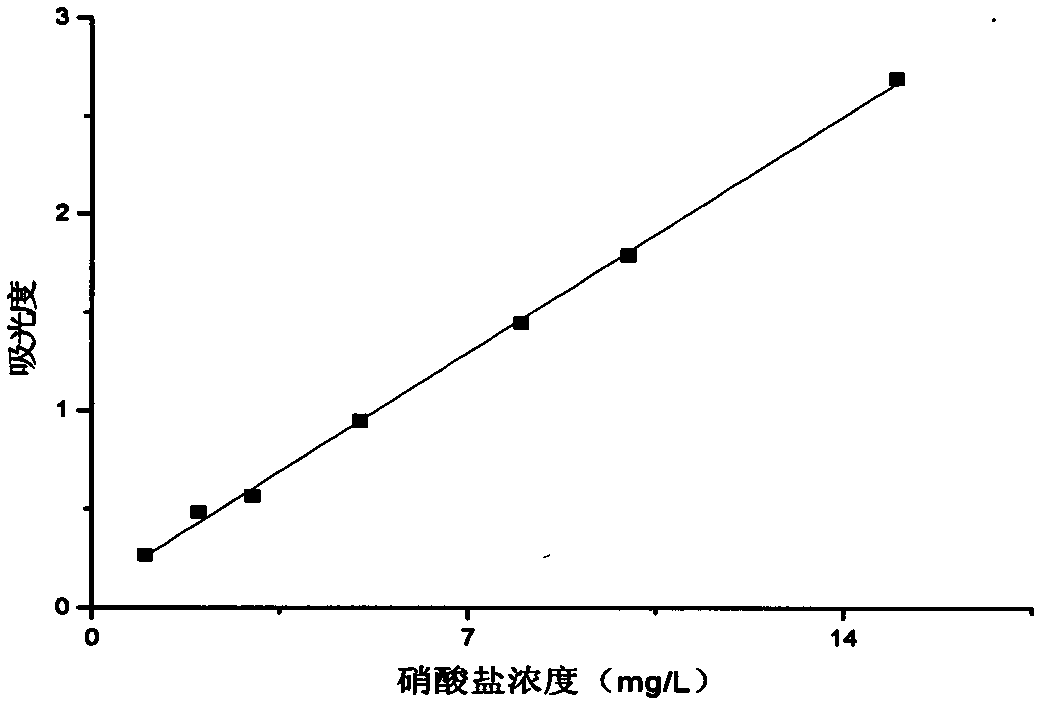

[0032] Pretreat the PP-g-VAm fiber sample with 0.1-1.0mol / L NaOH aq...

Embodiment 3

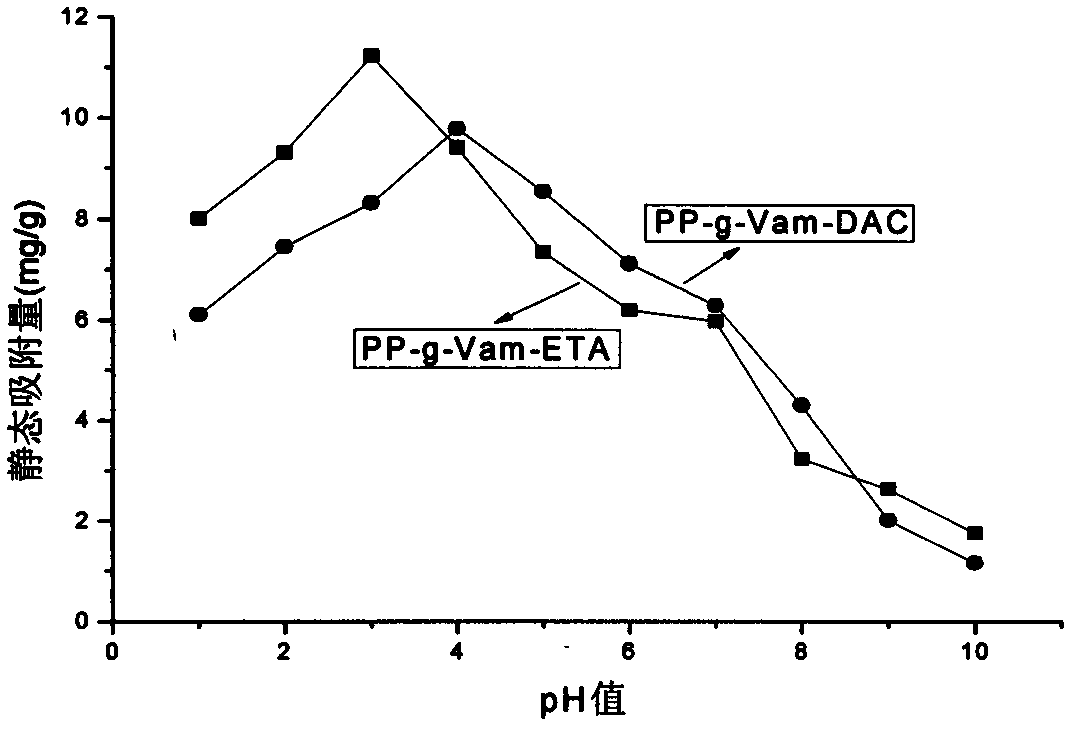

[0041] Embodiment 3: Grafting ETA to prepare PP-g-VAm-ETA fiber

[0042] Dissolve 2.63g of ammonium cerium nitrate in 60ml of 1mol / L nitric acid solution to obtain an initiator solution. In a 250ml three-neck flask equipped with a stirrer and a reflux condenser, add 100ml of isopropanol as a solvent, then add 5g of PP-g-VAm fiber, blow nitrogen, and then add cerium ammonium nitrate solution and 2,3-epoxy Propyltrimethylammonium chloride (ETA), system total volume 100ml, cerium ammonium nitrate concentration 0.75mmol / L, 2,3-epoxypropyltrimethylammonium chloride (ETA) concentration 20%, warming up to 80 ° C, stirred and reacted for 12h. After the reactant was cooled to 25°C, it was washed successively with 300ml of methanol and 300ml of acetone, and dried under vacuum at 60°C and -0.09MPa for 24h to obtain PP-g-VAm-ETA fibers. The strong base group content of the fiber is 3.1018mmol / g (dry fiber). The method for determining the content of strong basic groups in fibers refers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com