Light-blocking member for use in optical equipment

A technology for optical equipment and components, applied in the field of light-shielding components for optical equipment, can solve the problems of reduced wear resistance, insufficient adhesion, and reduced content of light-shielding films, so as to reduce the amount of lubricant compounded and improve the adhesion. , the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

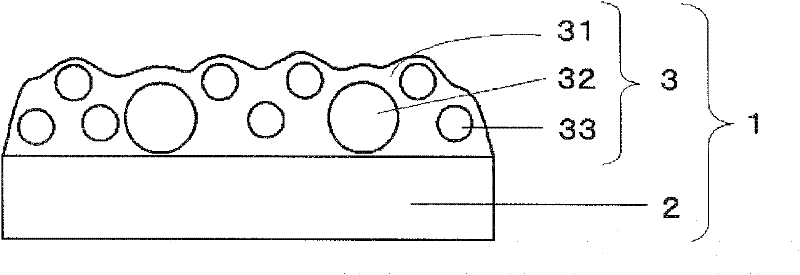

Image

Examples

Embodiment

[0072] Below, the present invention is further illustrated by examples. In addition, "part" and "%" are based on weight unless otherwise indicated.

[0073] 1. Fabrication of light-shielding parts for optical equipment

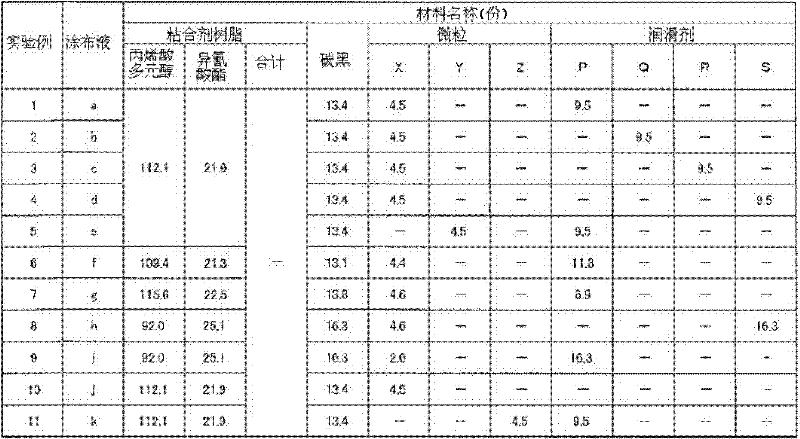

experiment example 1~19

[0075] As a substrate, a polyimide film (Kapton 200H: Toray DuPont Co.) with a thickness of 50 μm was used, and the coating for a light-shielding film of the following formulation was coated on both sides by the bar coating method so that the thickness when dry was 10 μm. Liquids a to s were dried to form light-shielding films A to S, and light-shielding members for optical devices of each experimental example were produced. In addition, the content (part) of the acrylic polyol etc. of the coating liquid for light-shielding films of the following formulation is shown in Table 1, 2. Moreover, the content rate (%) of the acrylic polyol etc. of the light-shielding film formed is shown in Table 3, 4.

[0076]

[0077] ・Acrylic polyol (solid content 50%) (parts described in Table 1)

[0078] (Acrydic A804: DIC Corporation)

[0079] ・Isocyanate (solid content 75%) (parts described in Table 1)

[0080] (Burnock DN980: DIC Corporation)

[0081] ・Carbon black (parts described in ...

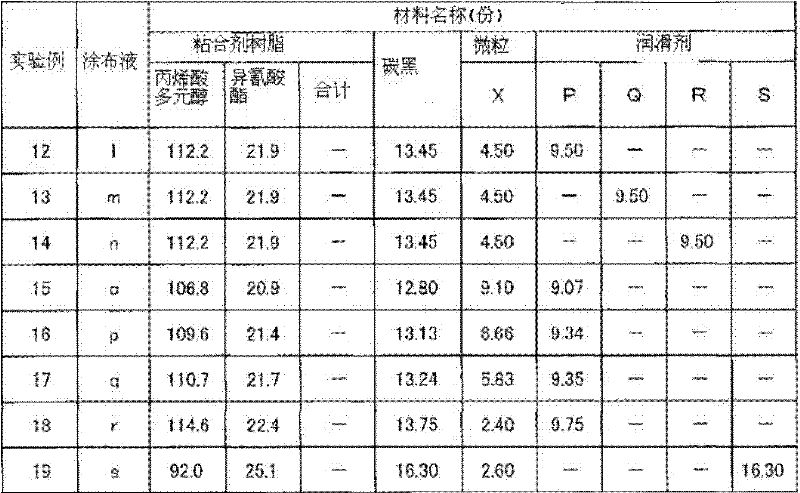

experiment example 12~19

[0133] About Experimental Examples 12-19, it is as follows.

[0134] In Experimental Example 19, the specific particulate lubricant used in Experimental Examples 12 to 18 was not used, and the content of the lubricant in the light-shielding film was high (16.30% by weight). As a relative effect, the adhesion could not be sufficiently improved. The content rate (64.8% by weight) of the agent resin. As a result, the adhesiveness and heat resistance of a light-shielding film are inferior. In addition, it was found that the adhesiveness and abrasion resistance of the light-shielding film tended to decrease as the weight ratio (lubricant / fine particle) in the light-shielding film increased (6.27).

[0135] In contrast, in Experimental Examples 12 to 18, since specific particulate lubricants were used, compared with Experimental Example 19, even if the content of the lubricant in the light-shielding film was reduced (16.30% by weight in Experimental Example 19), , Experimental Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com