Free-form surface lens and method of realizing shape-preserving coating for same

A curved lens, free technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of complexity and high cost, and achieve the effect of improving light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

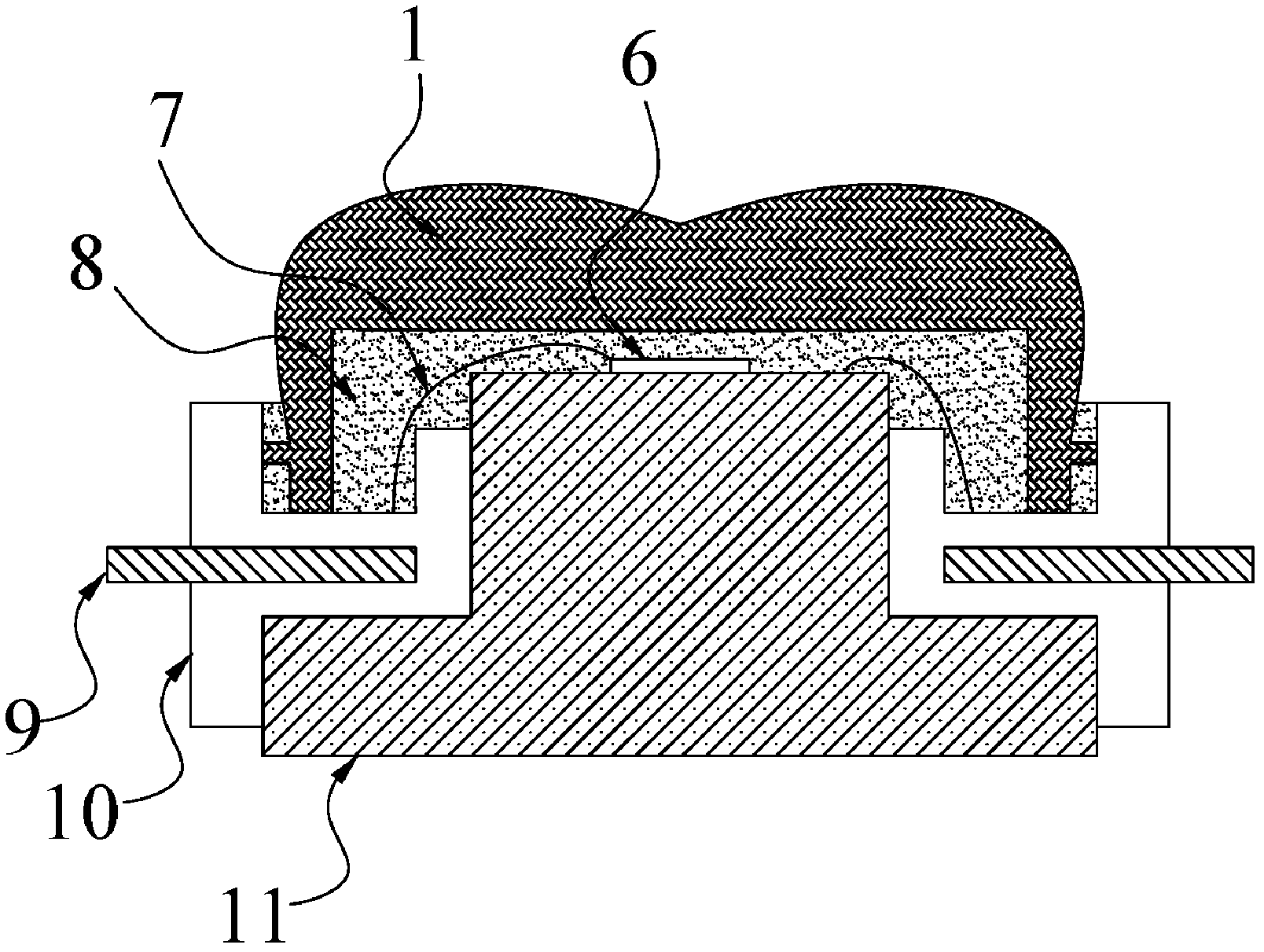

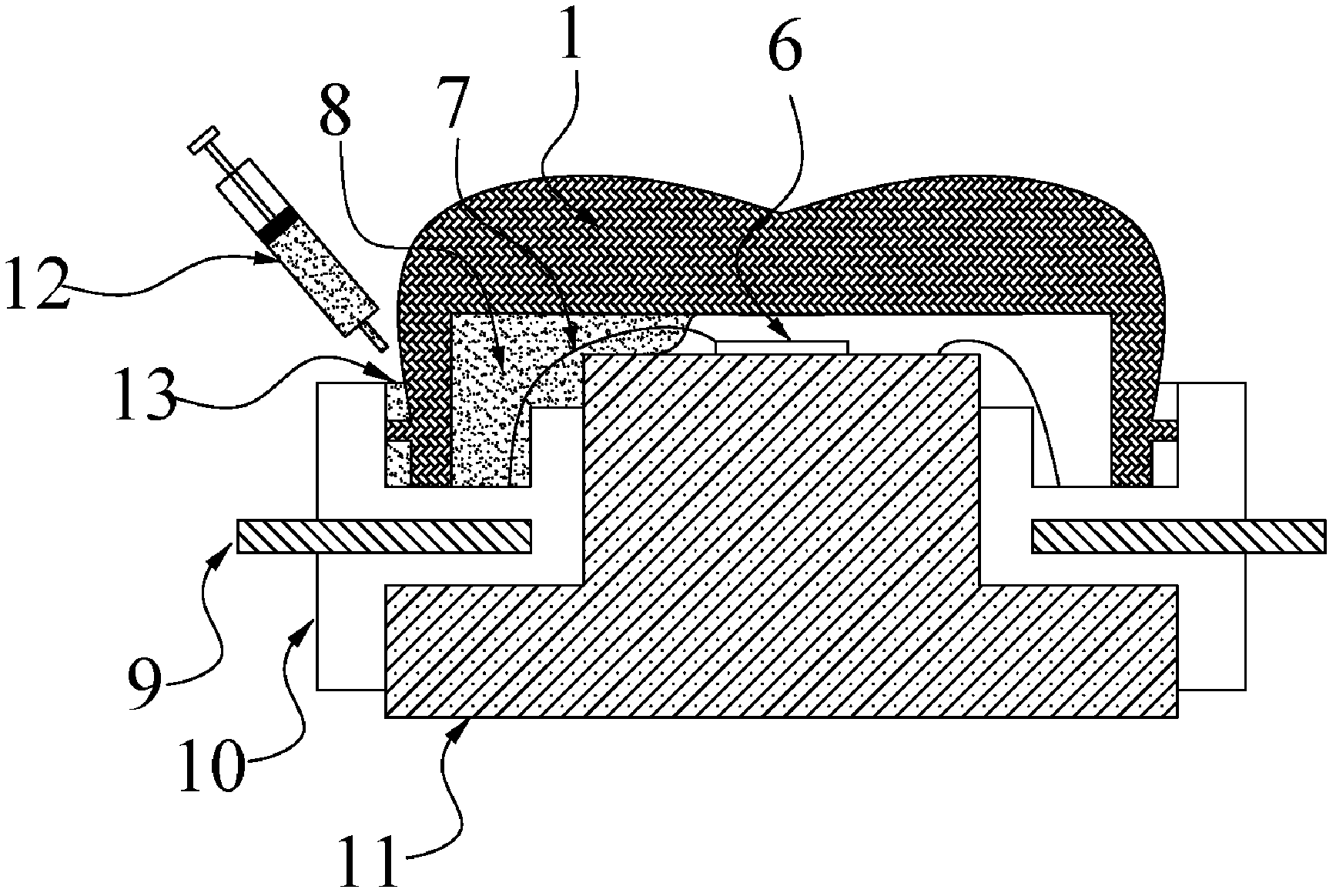

[0037] see figure 2 with image 3 , what is involved in this embodiment is the LED bracket package. The structure of the LED bracket is that the copper heat sink 11 and the lead frame 9 are fixed in the molding compound 10 , and the molding compound 10 is also fixed together with the free-form surface lens 1 . The LED chip 6 is fixed at the center of the copper heat sink 11 of the LED bracket, and the gold wire 7 connects the LED chip 6 with the lead frame 9 to form a continuous circuit. The free-form surface lens 1 has a rectangular cross section. The phosphor glue in the syringe 12 is dripped into the glue injection port 13 by a glue dispenser until the phosphor glue 8 flows out from another glue injection port 13, then the glue injection process is stopped. The glue material in the phosphor glue 8 is silica gel, and the phosphor is YAG phosphor. After the phosphor powder glue 8 reaches the equilibrium state between the free-form surface lens 1 and the LED bracket, it i...

example 2

[0039] see Figure 4 , The difference between this embodiment and Example 1 is that the cross section of the free-form surface lens 1 is trapezoidal.

example 3

[0041] see Figure 5, The difference between this embodiment and Example 1 is that the cross section of the free-form surface lens 1 is a rounded rectangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com