Method for producing dye-sensitized solar cell

A solar cell and dye sensitization technology, which is applied in the field of inorganic non-metallic material production, can solve the problems of high cost of photovoltaic cells, achieve the effects of improving photoelectric conversion efficiency, wide sunlight spectrum, and inhibiting electronic recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the battery preparation process, diatomite powder and titanium dioxide powder are mixed according to a certain ratio, and a photoanode with excellent photoelectric performance is prepared on a conductive substrate. The counter electrode is made of conductive glass with high light transmittance, which can reduce the reflection of visible light and improve the utilization rate of sunlight.

[0017] The photoanode adopts the method of preparing diatomite-doped titanium dioxide film layer on the conductive substrate. The counter electrode is made of conductive glass with high light transmission function, and the counter electrode has the function of increasing the transmittance of visible light and reducing the reflection of visible light. The doping amount of diatomite in the photoanodic titanium dioxide coating is 5%-50%, and the coating thickness is 0.5-3μm.

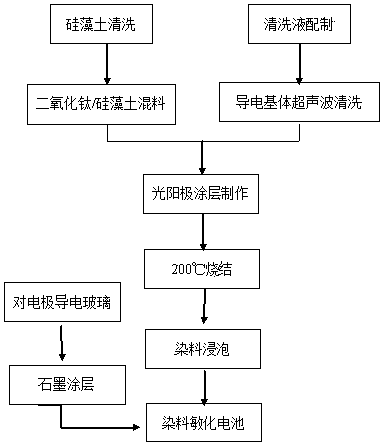

[0018] Such as figure 1 The process flow is shown as:

[0019] Conductive substrate cleaning: Prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com