Insulator umbrella skirt, insulators comprising umbrella skirt as well as manufacturing methods for insulator umbrella skirt and insulators

A technology for insulator sheds and insulators, applied in the direction of insulators, supporting insulators, electrical components, etc., can solve the problems of high mechanical strength of the surface layer, poor mechanical strength of the surface layer, and easy cracks, etc., and achieve simple manufacturing process, low raw material cost, and Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

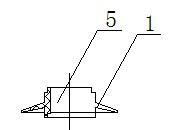

[0029] Such as figure 2 An insulator shed is shown, the shed is a hollow glass fiber reinforced plastic shed 1, and the hollow glass fiber reinforced plastic shed 1 is made of three-dimensional glass fiber three-dimensional fabric impregnated with epoxy resin.

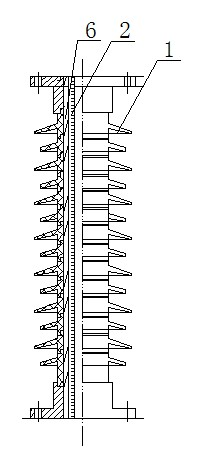

[0030] Such as image 3 The shown hollow insulator includes a hollow FRP shed 1, which is sequentially set on the hollow FRP insulator mandrel 2, and the hollow FRP shed 1 and the hollow FRP insulating mandrel 2 are bonded by epoxy resin 6.

[0031] Such as Figure 4 The shown solid insulator includes a hollow FRP shed 1, which is sequentially set on the solid FRP insulator mandrel 2, and the hollow FRP shed 1 and the solid FRP insulating mandrel 3 are bonded by epoxy resin 6.

[0032] A method for manufacturing an insulator shed, characterized in that:

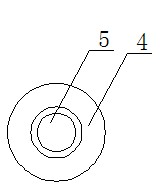

[0033] a. Make the three-dimensional glass fiber three-dimensional fabric as figure 1 As shown in the annular sheet 4, the center of the annular sheet 4 is a man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com