Test method for temperature evenness of hot plate

A technology of hot plate temperature and testing method, which is applied in the direction of semiconductor/solid-state device testing/measurement, photolithography exposure equipment, microlithography exposure equipment, etc., which can solve the problem of affecting temperature uniformity, regular replacement, and inability to accurately analyze data judgments Hot plate uniformity and other issues, to achieve the effect of quantitative uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

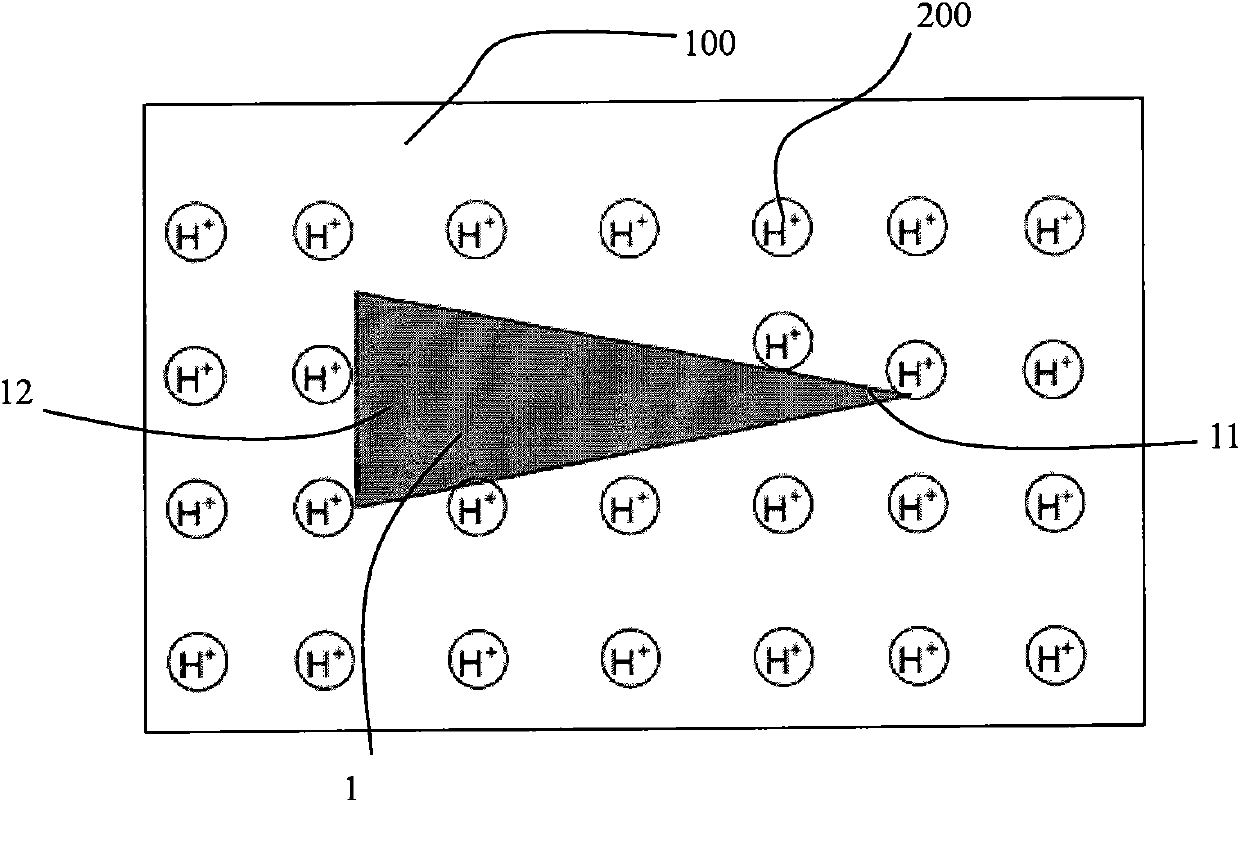

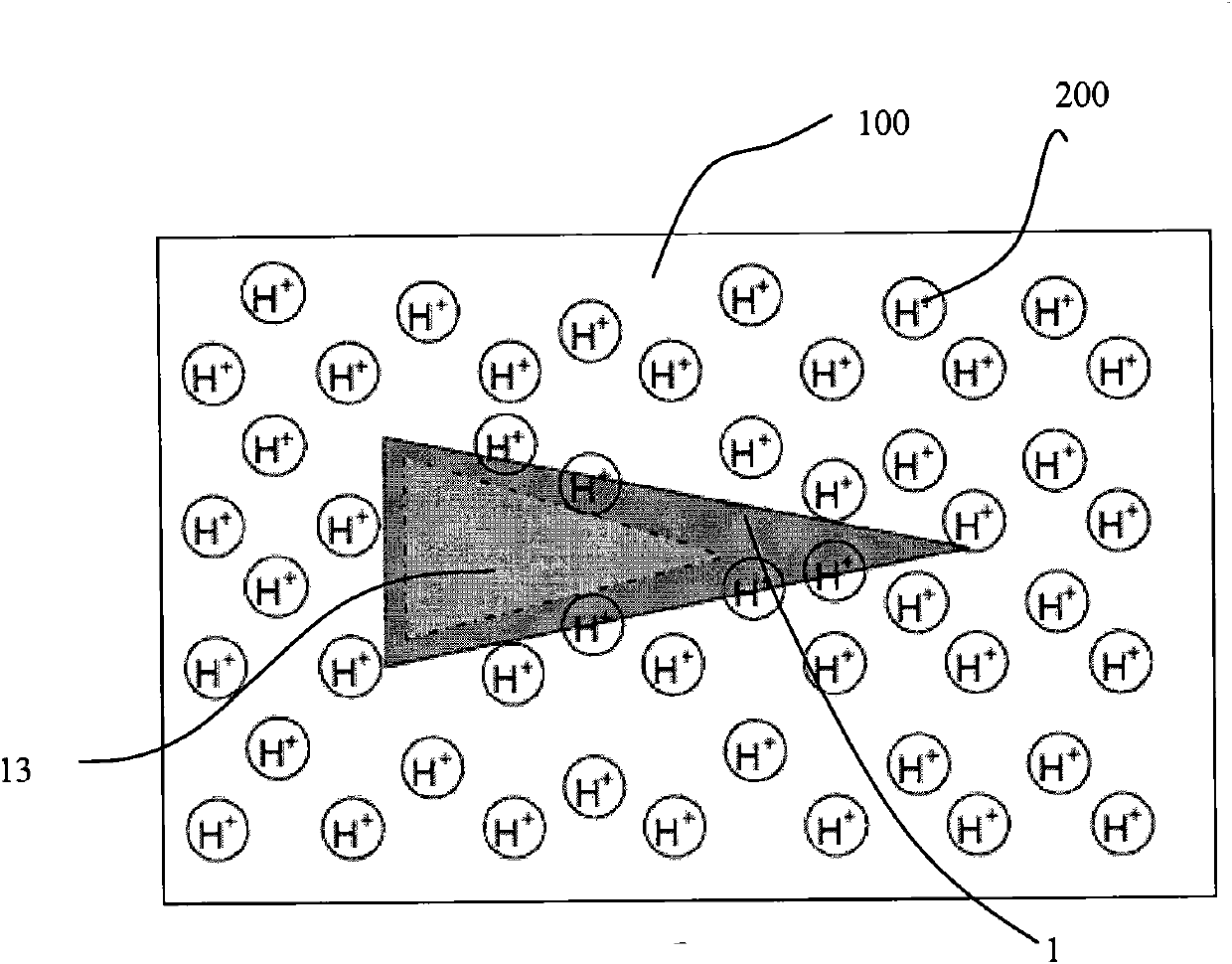

[0030] The hot plate uniformity test method of the present invention reflects the temperature uniformity of the hot plate by monitoring the influence of the post exposure bake (PEB, Post Exposure Bake) hot plate temperature difference on the shape of the specially designed pattern. These specially designed patterns are asymmetric structures, and the asymmetric part of the pattern has different degrees of sensitivity to temperature. see figure 1 and figure 2 , which shows the differential temperature sensitivity of the graphs of asymmetric structures during PEB.

[0031] figure 1 In the process, the pattern 1 with an asymmetric structure is placed on the photoresist plate 100, and the positive photoresist is coated on the wafer. In a preferred embodiment of the present invention, the positive photoresist is a positive deep ultraviolet chemically amplified (DUV CAR, DUV Chemically Amplified Photoresist) photoresist. Preferably, the positive photoresist is T-Butylester, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com