Method for inspecting current loop of main transformer sleeve by using zero lifting flow

A current loop and loop technology, applied in the phase angle between voltage and current, measuring current/voltage, measuring electricity and other directions, can solve problems such as inability to use, test current loop, lack of generator power in substations, etc., to ensure correct performance, avoid accidental shocks, reduce workload and test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

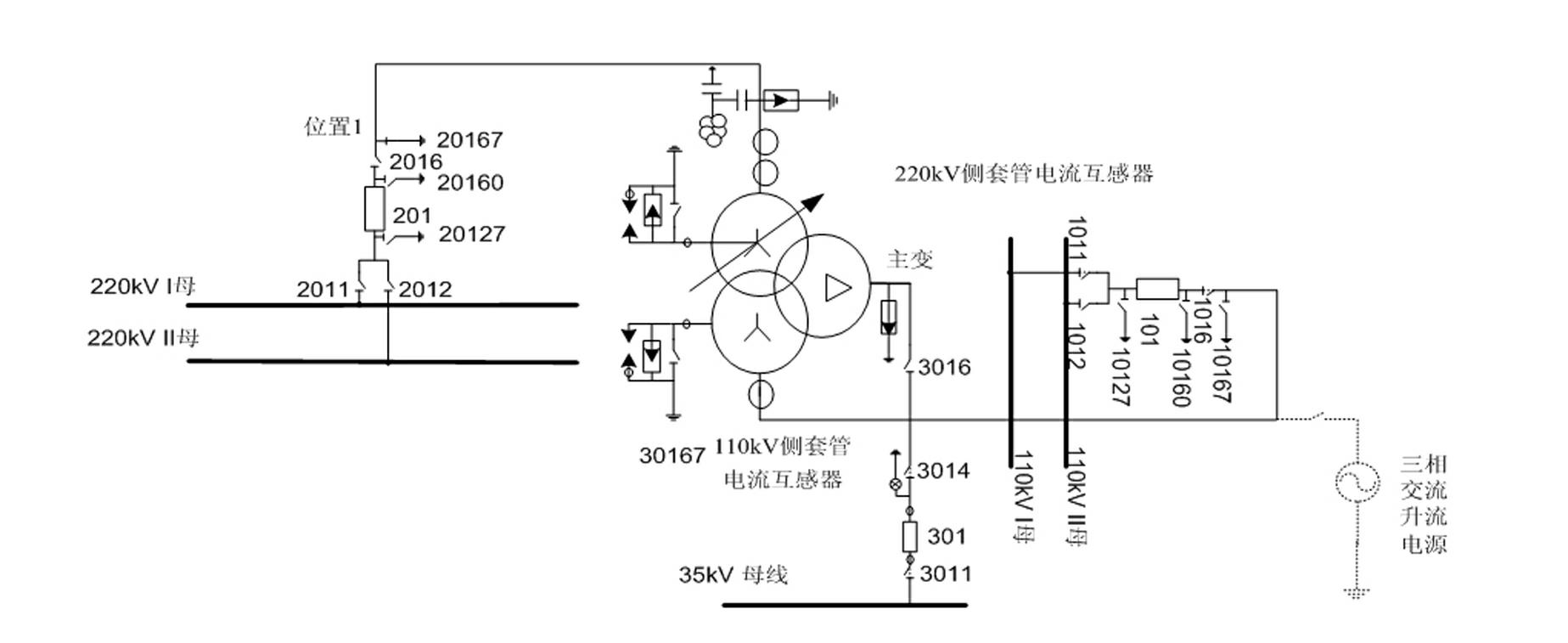

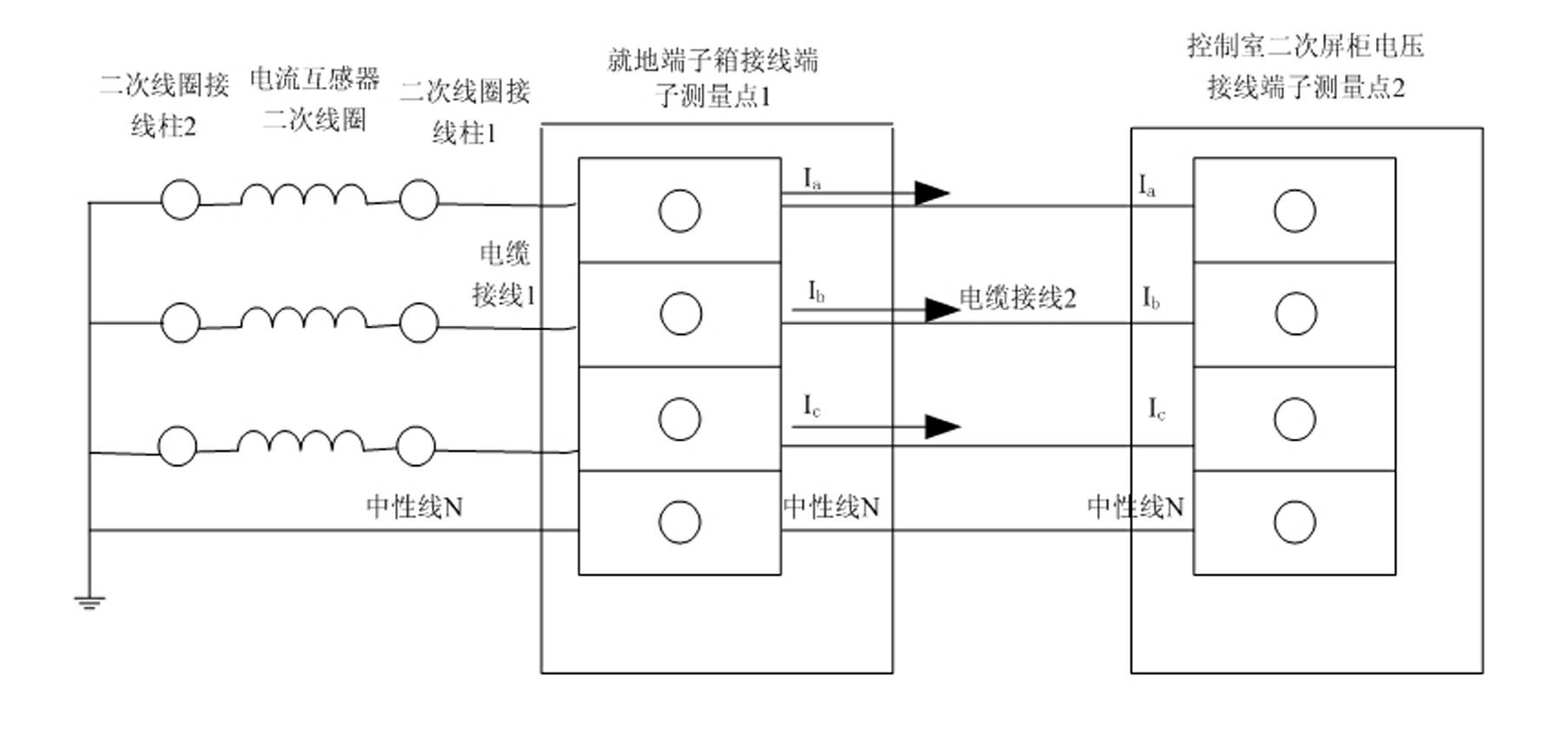

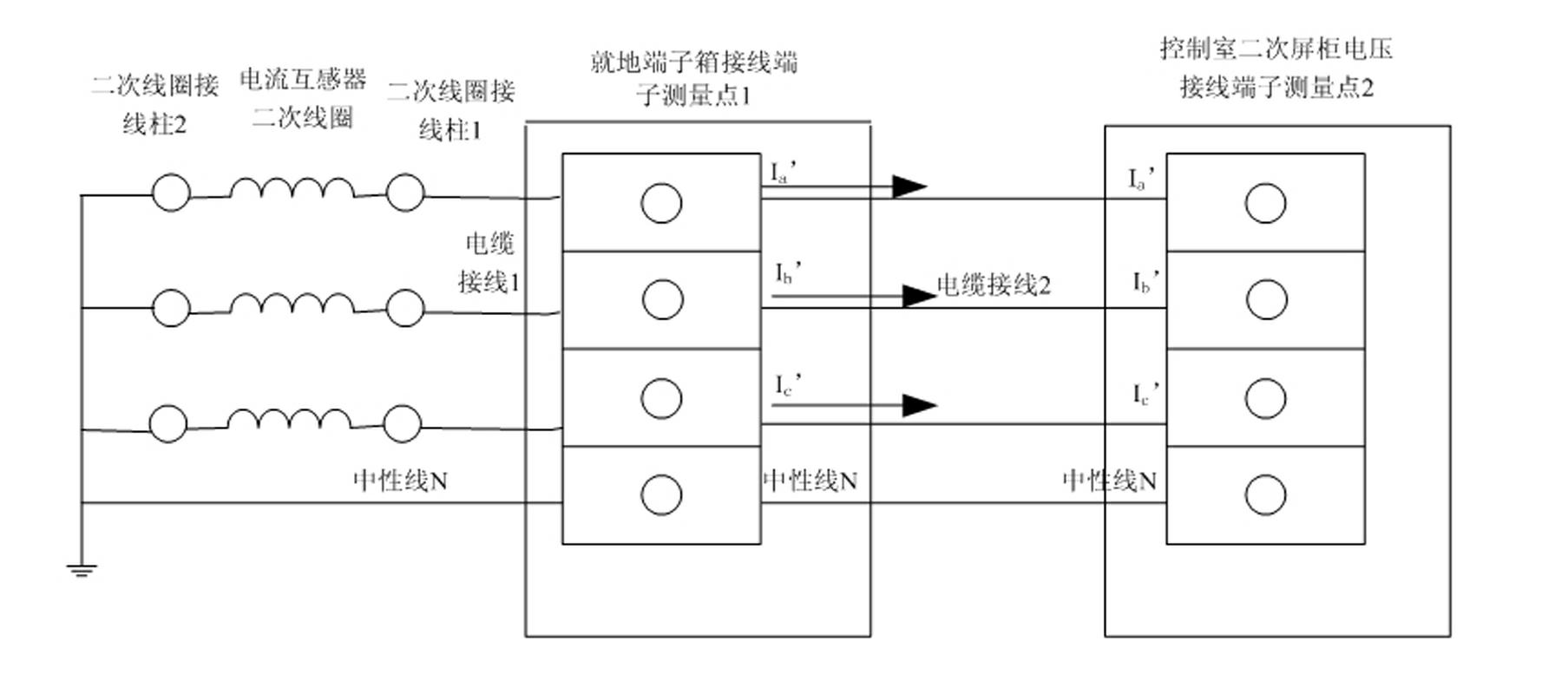

[0021] The method for checking the current loop of the main transformer bushing with zero rise current, the present invention is characterized in that: before the 220kV substation is put into production with live electricity, the following steps are carried out: Step 1, according to the order of one-to-one correspondence of cable connections, output the three-phase voltage regulator Use the A-phase circuit, B-phase circuit and C-phase circuit of the test line, which are respectively connected to the primary three-phase A-phase circuit, B-phase circuit and C-phase circuit on the 110kV side of the main transformer; set three-phase grounding on the 220kV side of the main transformer Short circuit point; step 2, close the test air switch, monitor the test current with a clamp meter, and monitor the secondary circuit current with a clamp phase meter; adjust the three-phase voltage regulator to slowly increase the three-phase test current from zero, so that When the secondary current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com